Hebei Qiao Wan Metal Products Co., Ltd.

By delivering high-quality products and outstanding service, we aim to be a trusted partner for businesses worldwide, providing solutions that meet the highest industry standards and stand the test of time.

-

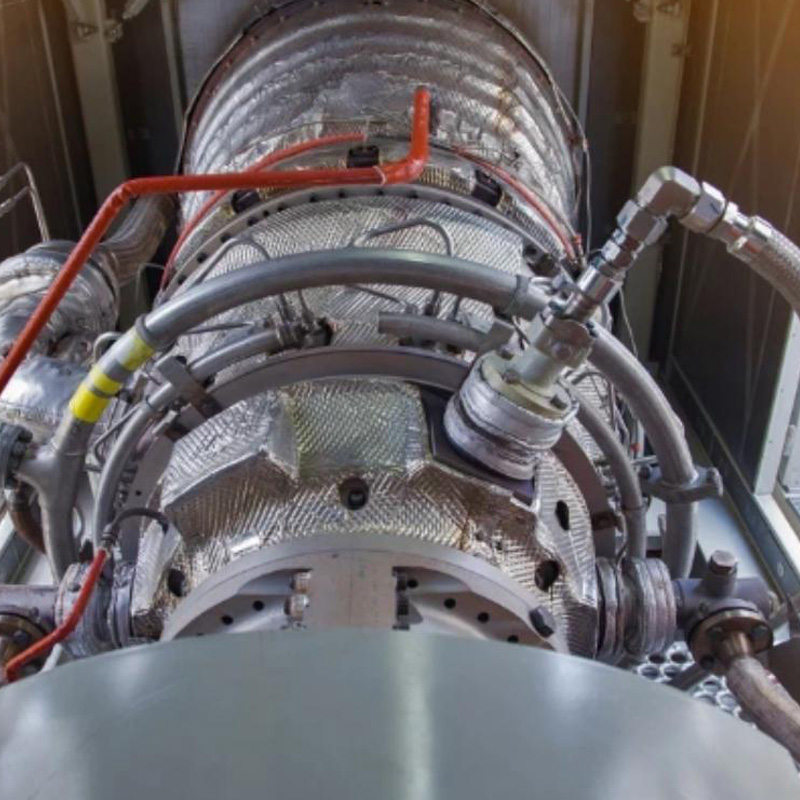

Metal Hose ApplicationChemical and Petrochemical IndustryThe chemical and petrochemical industries are among the primary sectors where metal hoses are indispensable. These industries deal with the transportation of highly corrosive, hazardous, and volatile chemicals. Metal hoses, typically constructed with materials like stainless steel, are used for the transfer of acids, solvents, fuels, and gases, ensuring safety and efficiency in environments where conventional hoses would quickly degrade. One of the main benefits of metal hoses is their resistance to chemical corrosion, which allows them to handle aggressive materials that would otherwise deteriorate rubber, plastic, or other flexible hoses.

Metal Hose ApplicationChemical and Petrochemical IndustryThe chemical and petrochemical industries are among the primary sectors where metal hoses are indispensable. These industries deal with the transportation of highly corrosive, hazardous, and volatile chemicals. Metal hoses, typically constructed with materials like stainless steel, are used for the transfer of acids, solvents, fuels, and gases, ensuring safety and efficiency in environments where conventional hoses would quickly degrade. One of the main benefits of metal hoses is their resistance to chemical corrosion, which allows them to handle aggressive materials that would otherwise deteriorate rubber, plastic, or other flexible hoses. -

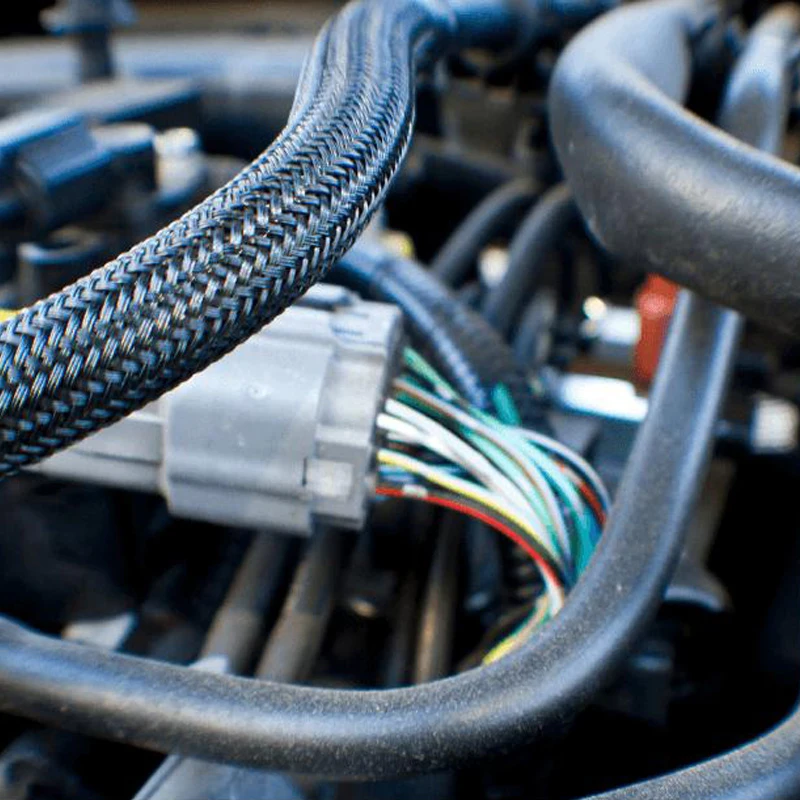

Metal Hose ApplicationAutomotive IndustryThe automotive industry relies heavily on a wide range of components that ensure vehicles and machines perform reliably under varying conditions. Among these components, metal hoses are particularly critical due to their flexibility, durability, and ability to handle high temperatures, pressures, and exposure to chemicals. In vehicles, metal hoses are commonly used in exhaust systems, fuel lines, air conditioning, power steering, and hydraulic systems, where they must endure harsh conditions while maintaining safety and performance.

Metal Hose ApplicationAutomotive IndustryThe automotive industry relies heavily on a wide range of components that ensure vehicles and machines perform reliably under varying conditions. Among these components, metal hoses are particularly critical due to their flexibility, durability, and ability to handle high temperatures, pressures, and exposure to chemicals. In vehicles, metal hoses are commonly used in exhaust systems, fuel lines, air conditioning, power steering, and hydraulic systems, where they must endure harsh conditions while maintaining safety and performance. -

Metal Hose ApplicationFood and Beverage IndustryThe food and beverage industry is highly regulated and demands strict hygiene standards, especially in the transport of liquids, gases, and powders. Metal hoses have become a vital part of the food and beverage manufacturing process due to their resistance to contamination, ease of cleaning, and ability to handle a wide range of temperatures and pressures. In this sector, metal hoses are used to transfer various food products such as milk, beer, wine, oils, and syrups, all of which require safe, sanitary, and efficient transportation.

Metal Hose ApplicationFood and Beverage IndustryThe food and beverage industry is highly regulated and demands strict hygiene standards, especially in the transport of liquids, gases, and powders. Metal hoses have become a vital part of the food and beverage manufacturing process due to their resistance to contamination, ease of cleaning, and ability to handle a wide range of temperatures and pressures. In this sector, metal hoses are used to transfer various food products such as milk, beer, wine, oils, and syrups, all of which require safe, sanitary, and efficient transportation. -

Metal Hose ApplicationHVAC (Heating, Ventilation, and Air Conditioning)In the HVAC industry, metal hoses play a critical role in ensuring the safe and efficient operation of heating, ventilation, and air conditioning systems in both residential and commercial buildings. These systems involve the transfer of refrigerants, water, and air between various components, and metal hoses provide the flexibility and durability needed to handle the high pressures and fluctuating temperatures typical of HVAC operations. Whether it's in large commercial air conditioning units or small residential heating systems, metal hoses ensure that these systems operate smoothly and efficiently.

Metal Hose ApplicationHVAC (Heating, Ventilation, and Air Conditioning)In the HVAC industry, metal hoses play a critical role in ensuring the safe and efficient operation of heating, ventilation, and air conditioning systems in both residential and commercial buildings. These systems involve the transfer of refrigerants, water, and air between various components, and metal hoses provide the flexibility and durability needed to handle the high pressures and fluctuating temperatures typical of HVAC operations. Whether it's in large commercial air conditioning units or small residential heating systems, metal hoses ensure that these systems operate smoothly and efficiently. -

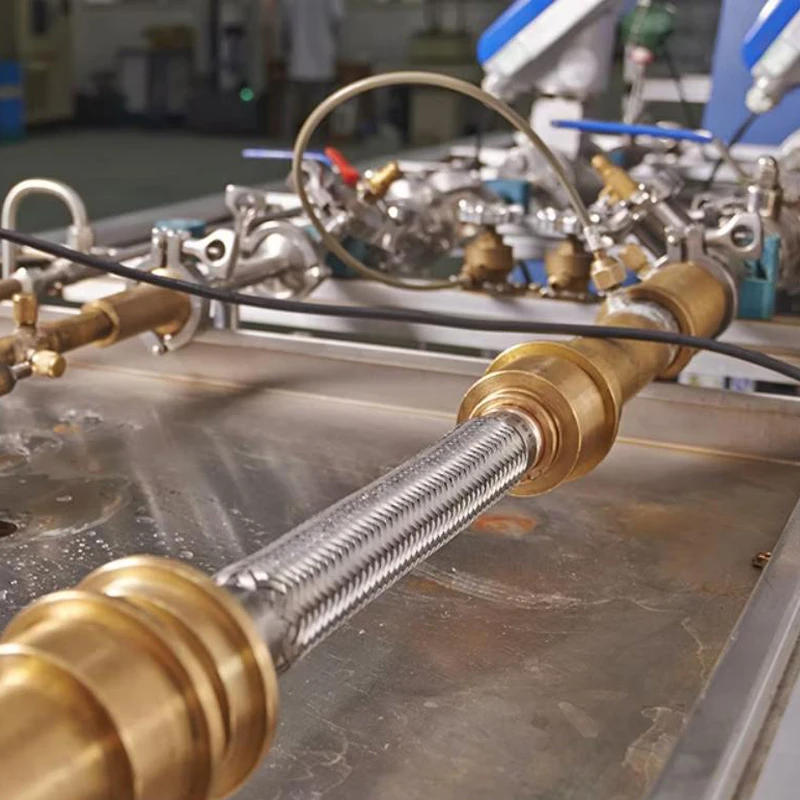

Polyurethane ApplicationOil and Gas IndustryThe oil and gas industry is one of the most challenging sectors for pipeline systems due to the harsh environments and extreme conditions involved in exploration, production, refining, and transportation. These operations require pipelines that can endure high pressures, extreme temperatures, and exposure to corrosive substances over long periods. Polyurethane lined pipes have emerged as a reliable and efficient solution for meeting these demands, offering superior performance compared to traditional steel or concrete pipelines.

Polyurethane ApplicationOil and Gas IndustryThe oil and gas industry is one of the most challenging sectors for pipeline systems due to the harsh environments and extreme conditions involved in exploration, production, refining, and transportation. These operations require pipelines that can endure high pressures, extreme temperatures, and exposure to corrosive substances over long periods. Polyurethane lined pipes have emerged as a reliable and efficient solution for meeting these demands, offering superior performance compared to traditional steel or concrete pipelines. -

Polyurethane ApplicationChemical Processing IndustryThe chemical processing industry operates in some of the most demanding environments, dealing with highly aggressive substances such as acids, alkalis, organic solvents, and other corrosive chemicals. These materials can rapidly degrade traditional piping systems, leading to frequent maintenance, costly downtime, and increased safety risks. Polyurethane lined pipes have become a preferred solution for this industry, thanks to their exceptional resistance to chemical attack, abrasion, and wear, as well as their ability to handle extreme temperatures and pressures.

Polyurethane ApplicationChemical Processing IndustryThe chemical processing industry operates in some of the most demanding environments, dealing with highly aggressive substances such as acids, alkalis, organic solvents, and other corrosive chemicals. These materials can rapidly degrade traditional piping systems, leading to frequent maintenance, costly downtime, and increased safety risks. Polyurethane lined pipes have become a preferred solution for this industry, thanks to their exceptional resistance to chemical attack, abrasion, and wear, as well as their ability to handle extreme temperatures and pressures. -

Polyurethane ApplicationMining and Mineral Processing IndustryThe mining and mineral processing industry is inherently tough on pipelines, largely due to the abrasive and corrosive nature of the materials being transported. Slurries, which are mixtures of water and fine mineral particles, are common in mining operations. These slurries contain solid materials such as ore, sand, and gravel, which can quickly erode traditional pipelines, leading to frequent failures, blockages, and expensive repairs. Polyurethane lined pipes offer an ideal solution to these challenges due to their superior abrasion resistance, chemical resistance, and durability, making them especially suited for high-demand environments like mining and mineral processing.

Polyurethane ApplicationMining and Mineral Processing IndustryThe mining and mineral processing industry is inherently tough on pipelines, largely due to the abrasive and corrosive nature of the materials being transported. Slurries, which are mixtures of water and fine mineral particles, are common in mining operations. These slurries contain solid materials such as ore, sand, and gravel, which can quickly erode traditional pipelines, leading to frequent failures, blockages, and expensive repairs. Polyurethane lined pipes offer an ideal solution to these challenges due to their superior abrasion resistance, chemical resistance, and durability, making them especially suited for high-demand environments like mining and mineral processing. -

Polyurethane ApplicationPower Generation IndustryThe power generation industry relies heavily on efficient and durable piping systems to transport various substances, such as cooling water, ash, steam, and chemical byproducts, often under extreme conditions. These systems must be resistant to high pressures, elevated temperatures, and the abrasive or corrosive substances involved in power generation processes. Polyurethane lined pipes offer an ideal solution for the power generation sector, due to their ability to withstand the demanding operational conditions typically found in thermal, nuclear, and renewable energy power plants.

Polyurethane ApplicationPower Generation IndustryThe power generation industry relies heavily on efficient and durable piping systems to transport various substances, such as cooling water, ash, steam, and chemical byproducts, often under extreme conditions. These systems must be resistant to high pressures, elevated temperatures, and the abrasive or corrosive substances involved in power generation processes. Polyurethane lined pipes offer an ideal solution for the power generation sector, due to their ability to withstand the demanding operational conditions typically found in thermal, nuclear, and renewable energy power plants. -

Polyurethane ApplicationWater and Wastewater Treatment IndustryThe water and wastewater treatment industry faces unique challenges when it comes to the reliability and durability of its pipeline systems. These systems must transport a wide variety of substances, including raw water, treated water, wastewater, sludge, and chemicals, many of which are abrasive, corrosive, or both. As a result, the need for resilient piping systems that can perform consistently over time without frequent maintenance is essential. Polyurethane lined pipes are increasingly being adopted in water and wastewater treatment plants because of their superior chemical resistance, abrasion resistance, and ability to handle extreme operational conditions. These qualities ensure that the systems operate efficiently while minimizing the risk of failures and reducing long-term maintenance costs.

Polyurethane ApplicationWater and Wastewater Treatment IndustryThe water and wastewater treatment industry faces unique challenges when it comes to the reliability and durability of its pipeline systems. These systems must transport a wide variety of substances, including raw water, treated water, wastewater, sludge, and chemicals, many of which are abrasive, corrosive, or both. As a result, the need for resilient piping systems that can perform consistently over time without frequent maintenance is essential. Polyurethane lined pipes are increasingly being adopted in water and wastewater treatment plants because of their superior chemical resistance, abrasion resistance, and ability to handle extreme operational conditions. These qualities ensure that the systems operate efficiently while minimizing the risk of failures and reducing long-term maintenance costs.

Related News

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.