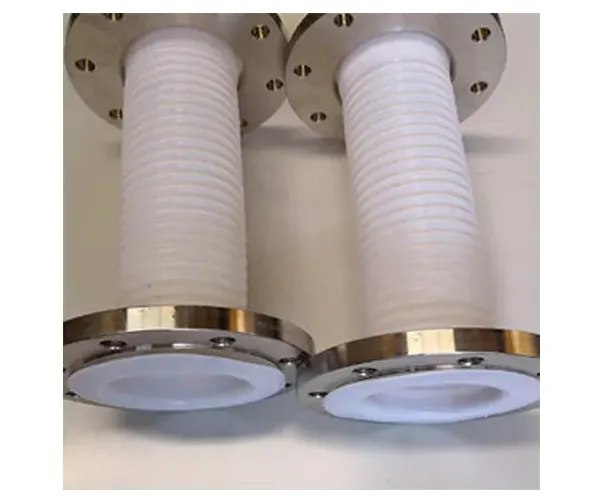

Structure and Materials

Advantages

PTFE bellows offer numerous advantages over other materials such as rubber or metal bellows.

They provide a long-lasting, chemical-resistant, and flexible sealing solution for harsh environments.

Their ability to absorb movement, thermal expansion, and vibrations makes them an ideal choice in applications where other materials might fail.

Moreover, their non-stick properties ensure smooth operation with minimal maintenance, reducing operational costs.

Key Features

- 1.Chemical Resistance: PTFE is highly resistant to corrosion and chemical attack, making it suitable for aggressive chemical environments.

2. High-Temperature Resistance: PTFE can withstand temperatures from -200°C to +260°C, which is ideal for high-temperature applications.

3.Low Friction: PTFE’s low friction properties allow for smooth operation, minimizing wear and tear on moving parts.

4. Flexibility and Expansion: PTFE bellows can handle axial and lateral movements, making them suitable for absorbing shocks and reducing stress in mechanical systems.

5. Durability: PTFE is highly durable and can resist abrasion, ensuring long service life even in challenging environments.

PTFE bellows are commonly used in industries such as:

- Chemical Processing: For sealing and protecting systems that handle aggressive or corrosive chemicals.

- Pharmaceuticals: To prevent contamination and maintain sanitary conditions in sensitive manufacturing processes.

- Food Processing: To ensure safe handling of food-grade materials, where non-reactive and non-toxic materials are critical.

- Semiconductor and Electronics: In systems that require high purity and resistance to chemicals and heat.

- Energy: In power plants or other high-temperature systems where thermal expansion needs to be accommodated.

PTFE bellows are essential components in many industrial applications where flexibility, chemical resistance, and durability are required.

Their ability to withstand extreme conditions and their versatility in handling thermal expansion, movement, and pressure make them indispensable in modern engineering.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.

Related News