Structure and Materials

Advantages

Polyurethane screen panels offer numerous advantages over traditional screen materials.

Their wear resistance ensures prolonged operational life, reducing maintenance costs and downtime.

The lightweight construction lowers energy consumption and stress on machinery, while the customizable designs ensure optimal performance in diverse applications.

Furthermore, their corrosion resistance and low noise levels make them ideal for both dry and wet screening environments.

Key Features

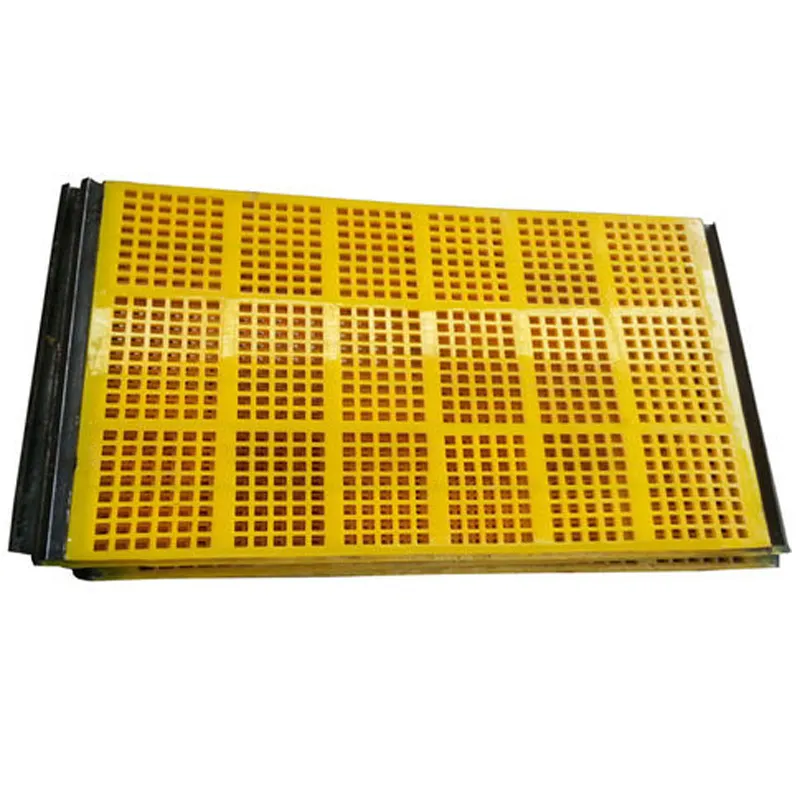

- 1. Wear Resistance: Polyurethane’s exceptional resistance to abrasion significantly extends the lifespan of the screen panels, even when used in high-wear environments.

2. Corrosion Resistance: The non-metallic nature of polyurethane ensures resistance to rust and chemical degradation, making the panels suitable for wet and corrosive conditions.

3. Lightweight and Easy Installation: Compared to metal screens, polyurethane panels are lightweight, reducing the load on screening equipment and simplifying installation and replacement.

4. Low Noise Levels: Polyurethane panels reduce operational noise, providing a quieter working environment.

5. Customizability: Polyurethane screen panels can be tailored to meet specific requirements, such as aperture size, panel thickness, and modular designs, ensuring compatibility with various screening systems.

Polyurethane screen panels are widely used in:

- Mining: For classifying and dewatering ores, coal, and minerals.

- Aggregate Production: In gravel, sand, and stone processing plants.

- Wastewater Treatment: For separating solid particles from liquid effluents.

- Chemical Processing: For screening and filtering corrosive or abrasive materials.

In conclusion, polyurethane screen panels are indispensable for modern material processing operations, combining durability,

efficiency, and adaptability to enhance productivity and reduce costs in challenging industrial applications.

Polyurethane Screen Panels Is Impact-Resistant, Which Is a Good Helper for Mine Screening.

Contact Us

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.

Related News