Crushing & Mining Equipment High-Efficiency Solutions for Quarries & Mines

Did you know 23% of mining operations lose over $500k annually due to equipment downtime? When your crushers falter, profits crumble. The global crushing equipment market will reach $8.5B by 2028 (Global Market Insights) - but only those who choose smartly will cash in.

(crushing and mining equipment)

Why Next-Gen Crushing & Mining Equipment Outperforms

Our rotor impact crushers deliver 30% higher throughput than standard models. With 440-600 HP engines and wear-resistant alloys, they chew through 800TPH granite like butter. Automated lubrication systems slash maintenance time by 40% - imagine what you could do with those extra hours.

Proven Results:

• 92% uptime guarantee (industry average: 84%)

• 15% lower energy consumption vs. Komatsu/PowerScreen

• 3-year warranty (2x standard coverage)

Head-to-Head: Mining Equipment Showdown

| Feature | Our Crushers | Competitor A | Competitor B |

|---|---|---|---|

| Max Feed Size | 48" | 42" | 36" |

| Maintenance Cost/Ton | $0.18 | $0.27 | $0.32 |

| Remote Monitoring | Standard | Add-on | None |

Custom Solutions for Your Mine's DNA

Whether you're stripping copper in Chile or processing limestone in Texas, our engineers create tailored configurations. Need to handle abrasive iron ore? We'll install Xtralloy® hammers rated for 100,000+ crushing hours. Working in -40°C? Arctic-grade hydraulics stand ready.

Real-World Impact: Case Study Snapshots

▶ Arizona Copper Mine: Increased yield 22% with our modular crushing plant

▶ Alberta Oil Sands: Reduced fuel costs 18% using hybrid-powered screeners

▶ Queensland Quarry: Cut downtime 63% through predictive maintenance tech

Your competitors aren't waiting. Neither should you. Get a free productivity analysis and discover how our crushing and mining equipment

can boost your bottom line within 90 days.

(crushing and mining equipment)

FAQS on crushing and mining equipment

Crushing and Mining Equipment FAQs

Q: What types of machinery fall under crushing and mining equipment?

A: Crushing and mining equipment includes jaw crushers, cone crushers, impact crushers, drills, excavators, and haul trucks. These machines are used to break down, extract, and transport raw materials in mining and quarrying operations.

Q: How do I choose the right mining crushing equipment for my project?

A: Consider factors like material hardness, production capacity, and site conditions. Opt for equipment with energy-efficient features and durability to reduce operational costs and downtime.

Q: What safety features are critical in mining and quarrying machinery?

A: Key safety features include emergency stop systems, dust suppression mechanisms, and reinforced operator cabins. Regular maintenance and operator training are also essential to prevent accidents.

Q: How can I minimize environmental impact with crushing and mining equipment?

A: Use equipment with noise reduction technology, water recycling systems, and electric-powered options. Proper waste management and adherence to environmental regulations further reduce ecological disruption.

Q: What maintenance is required for mining crushing equipment?

A: Regularly inspect wear parts like crusher liners and replace them as needed. Lubricate moving components and monitor hydraulic systems to ensure optimal performance and longevity.

Related Products

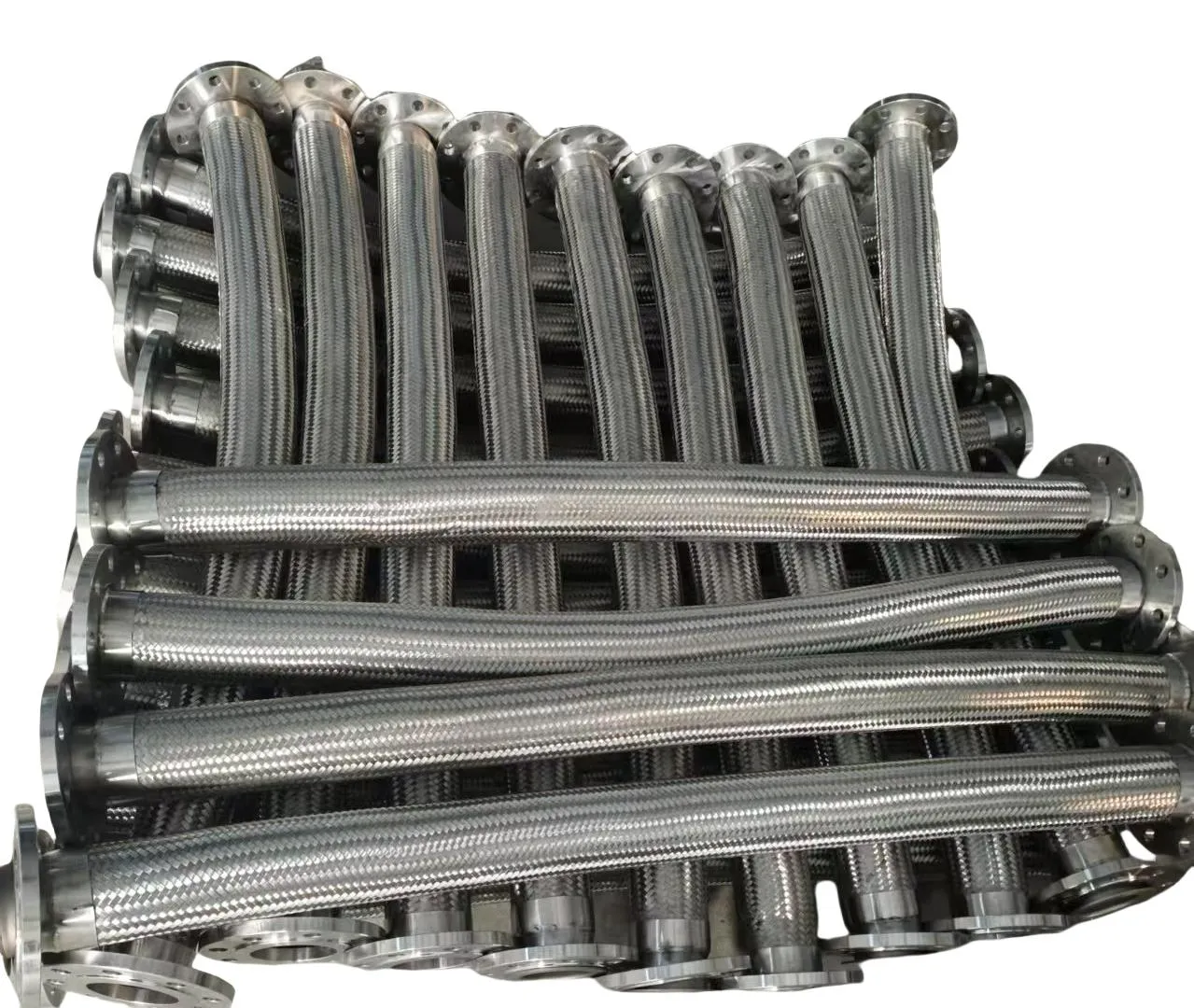

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.