Iron Ore Mining & Processing Equipment Heavy-Duty Solutions

- Industry Overview & Economic Impact

- Technological Innovations Driving Efficiency

- Critical Machinery for Mining & Ore Processing

- Vendor Comparison: Performance Metrics

- Tailored Solutions for Diverse Mining Needs

- Case Studies: Operational Success Stories

- Sustainable Practices in Iron Ore Processing

(iron ore mining and processing)

Iron Ore Mining and Processing: Industry Overview & Economic Impact

Global iron ore production reached 2.5 billion metric tons in 2023, with Australia, Brazil, and China dominating 78% of output. The sector contributes $350 billion annually to the global economy, fueled by steel demand from construction (52%) and automotive sectors (28%). Emerging automation technologies have reduced extraction costs by 17% since 2020, while ore grades below 60% Fe now require advanced beneficiation systems to maintain profitability.

Technological Innovations Driving Efficiency

Modern processing plants integrate AI-powered sorting systems that improve recovery rates by 23-29%. High-pressure grinding rolls (HPGR) reduce energy consumption by 34% compared to traditional ball mills. Real-time slurry density sensors enable 99.8% precision in ore concentration, while autonomous drilling rigs achieve 22% faster penetration rates in hard rock formations.

Critical Machinery for Mining & Ore Processing

Essential equipment includes:

- 400-ton electric hydraulic shovels (bucket capacity: 36m³)

- Dual-powered crushers with 2,500 TPH capacity

- Magnetic separators achieving 96.5% Fe purity

- Tailings management systems recycling 89% process water

Vendor Comparison: Performance Metrics

| Vendor | Throughput (TPH) | Energy Efficiency | Maintenance Cost/Hour | Automation Level |

|---|---|---|---|---|

| Komatsu | 2,200 | 88 kWh/ton | $145 | Level 4 |

| Sandvik | 1,950 | 92 kWh/ton | $162 | Level 3 |

| Caterpillar | 2,400 | 84 kWh/ton | $178 | Level 4 |

Tailored Solutions for Diverse Mining Needs

Modular processing plants now enable 45-day deployment for remote sites, handling ore grades from 35% to 68% Fe. Customizable flotation circuits adapt to specific gangue mineral compositions, while hybrid power systems cut diesel dependency by 63% in off-grid operations. Slope stability monitors provide 14-day predictive alerts for open-pit mines.

Case Studies: Operational Success Stories

Project Atlas (Western Australia): Implemented AI-driven sorting + HPGR combination, achieving 31% yield improvement and $18/ton cost reduction. Carajás Mine (Brazil): Deployed autonomous haulage systems, reducing fuel consumption by 28% across 120 vehicles. Kiruna Complex (Sweden): Installed underground optical sorting, decreasing waste processing by 410,000 tons annually.

Sustainable Iron Ore Mining and Processing

Leading operations now achieve 92% material utilization through dry stacking tailings and sensor-based ore sorting. Carbon capture systems integrated with pelletization plants reduce Scope 1 emissions by 41%. Water recycling rates exceed 85% in advanced facilities, while bioleaching techniques recover 74% of rare earth elements from processing residues.

(iron ore mining and processing)

FAQS on iron ore mining and processing

Q: What machinery is essential for iron ore mining and processing?

A: Key equipment includes drills, bulldozers, crushers, and conveyor systems. Mining and quarrying machinery like excavators and haul trucks are critical for extraction. Processing plants use grinding mills, magnetic separators, and pelletizing machines.

Q: How does iron ore processing work after mining?

A: Ore is crushed, screened, and ground to a fine powder. Magnetic separation or flotation removes impurities like silica. The refined ore is then pelletized or sintered for industrial use.

Q: What are common challenges in iron ore mining and ore processing?

A: Challenges include managing low-grade ore and environmental regulations. Dust control and wastewater management are critical in processing. Equipment wear and energy costs also pose operational hurdles.

Q: Why is environmental monitoring important in iron ore mining?

A: Mining and processing can cause land degradation and water pollution. Monitoring ensures compliance with sustainability standards. Technologies like dust suppressants and recycling systems mitigate environmental impacts.

Q: What technologies improve efficiency in mining and ore processing?

A: Automation and AI optimize equipment performance and ore sorting. Advanced sensors enhance real-time quality control during processing. Energy-efficient machinery reduces operational costs and carbon footprint.

Related Products

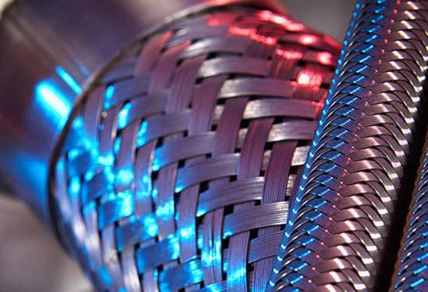

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.