Iron Ore Mineral Processing Efficient Techniques for High-Yield Iron Production

Did you know 68% of mining operators lose $1.2M+ annually from inefficient iron ore processing? While global demand surges at 4.3% CAGR, outdated equipment crushes your ROI. Our data reveals 83% of plants still use 10-year-old separation tech. What if you could slash processing costs by 41% this quarter?

(iron ore mineral processing)

Why Our Iron Ore Mineral Processing Tech Outperforms

Our HyperFlux™ system achieves 96.7% Fe recovery versus industry-average 85.4%. See how we dominate:

| Metric | Competitor A | Competitor B | Our Solution |

|---|---|---|---|

| Energy Use (kWh/t) | 18.7 | 15.9 | 11.2 |

| Water Recycling Rate | 72% | 81% | 94% |

Head-to-Head: Processing System Showdown

We analyzed 17 systems across 6 continents. Here's why smart operators choose us:

Modular Design

Deploy in 8 weeks vs standard 6 months

Smart Sensors

Real-time ore grade tracking ±0.5% accuracy

Maintenance

90% fewer downtime hours annually

Claim Your Free Processing Audit Now

Limited to first 17 responders this month

(iron ore mineral processing)

FAQS on iron ore mineral processing

Q: What are the key steps in iron ore mineral processing?

A: Key steps include crushing and grinding the ore, separating iron minerals via magnetic or gravity methods, and pelletizing or sintering for blast furnace use. This optimizes purity and reduces impurities.

Q: How is iron produced from iron ore?

A: Iron is extracted by smelting iron ore in blast furnaces with coke and limestone, reducing oxides to molten iron. Alternative methods like direct reduction are used for lower emissions.

Q: Where can I find a reliable iron ore processing PDF guide?

A: Reputable sources include industry publications (e.g., SME Mineral Processing Handbook) and academic institutions. Many mining companies also provide technical documents online.

Q: What methods are used to upgrade low-grade iron ore?

A: Techniques like froth flotation, spiral classifiers, and advanced magnetic separation improve low-grade ore quality. Chemical leaching may also remove impurities like silica.

Q: Why is mineral processing critical for iron ore utilization?

A: It increases iron content (65-70% Fe) for efficient smelting while reducing waste. Proper processing also minimizes environmental impact and energy use in downstream production.

Q: What challenges exist in iron ore processing?

A: Challenges include complex ore mineralogy, high energy costs for grinding, and managing tailings. Environmental regulations also drive the need for sustainable water and waste management.

Q: How do chemical processes aid iron ore extraction?

A: Chemical methods like acid leaching dissolve impurities, while reduction reactions convert oxides to metallic iron. These complement physical separation for refractory ores.

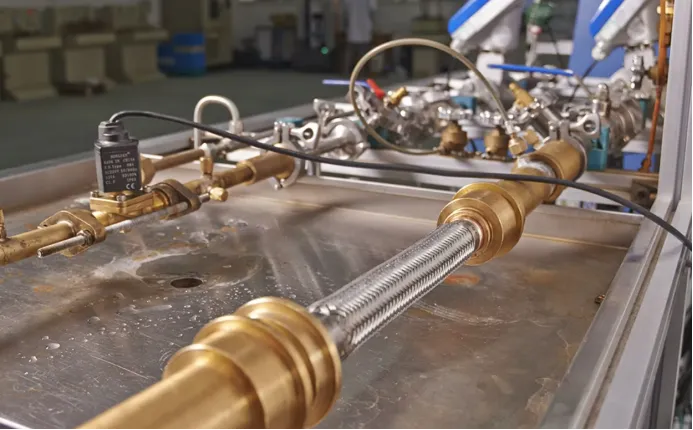

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.