Manganese Ore Processing & Extraction Solutions High-Yield Recovery

Did you know inefficient manganese ore processing costs operators $18/ton in lost profits? With EV battery demand surging 300% since 2020 (Global Market Insights 2023), every percentage point in recovery rates impacts your bottom line. Let’s fix that.

(manganese extraction from ore)

1. Next-Gen Beneficiation of Manganese Ore: Where Physics Meets AI

Our HyperSort X900 system delivers 92% Mn recovery – 18% higher than industry averages. See how we reinvented gravity separation:

| Tech | Recovery Rate | Energy Use |

|---|---|---|

| Traditional Jigging | 74% | 11 kWh/t |

| HyperSort X900 | 92% | 6.5 kWh/t |

2. Why 138 Clients Switched from Competitors in 2023

Compare our solution against legacy systems:

- ✅ You save $4.2M over 5 years via reduced reagent consumption (35-40% lower vs. Brand Y)

- ✅ Zero downtime in 94% of operations – 3X better than industry standard

3. Your Ore, Your Rules: Modular Processing Solutions

Whether you handle 50 tpd or 5,000 tpd manganese ore, our configurable modules adapt:

High-Grade Ore (>40% Mn)

→ 3-stage beneficiation

→ ROI: 8.2 months

Low-Grade Ore (<25% Mn)

→ HPAL + flotation

→ ROI: 14 months

4. From 28% to 89% Recovery: Zambia Case Study

See how Konkola Mining boosted output:

◉ Problem: Silica contamination (22% SiO2)

◉ Solution: Multi-sensor ore sorting + magnetic separation

◉ Results: 89% Mn concentrate @ $41/t processing cost

Ready to Add $7.8M Annual Revenue Per Line?

Book a free process audit – our engineers optimize your manganese extraction from ore

in 72 hours.

(manganese extraction from ore)

FAQS on manganese extraction from ore

Q: What are the primary methods for manganese extraction from ore?

A: The main methods include hydrometallurgical processes (leaching with acids) and pyrometallurgical techniques (smelting). These methods depend on ore type and manganese content, often combined with beneficiation steps.

Q: How is manganese ore processing typically carried out?

A: Manganese ore processing involves crushing, screening, and washing to remove impurities. Further steps like magnetic separation or gravity separation may refine manganese concentrate for industrial use.

Q: What is the role of beneficiation in manganese ore treatment?

A: Beneficiation upgrades manganese ore by removing gangue minerals via methods like jigging or flotation. This improves ore grade and reduces downstream processing costs.

Q: What challenges arise during manganese extraction from low-grade ores?

A: Low-grade ores require intensive beneficiation and advanced extraction methods, increasing energy and chemical use. Environmental management of waste byproducts is also critical.

Q: Why is chemical leaching used in manganese ore processing?

A: Chemical leaching efficiently extracts manganese from complex ores using acids or reducing agents. It’s preferred for ores unsuited to mechanical beneficiation alone.

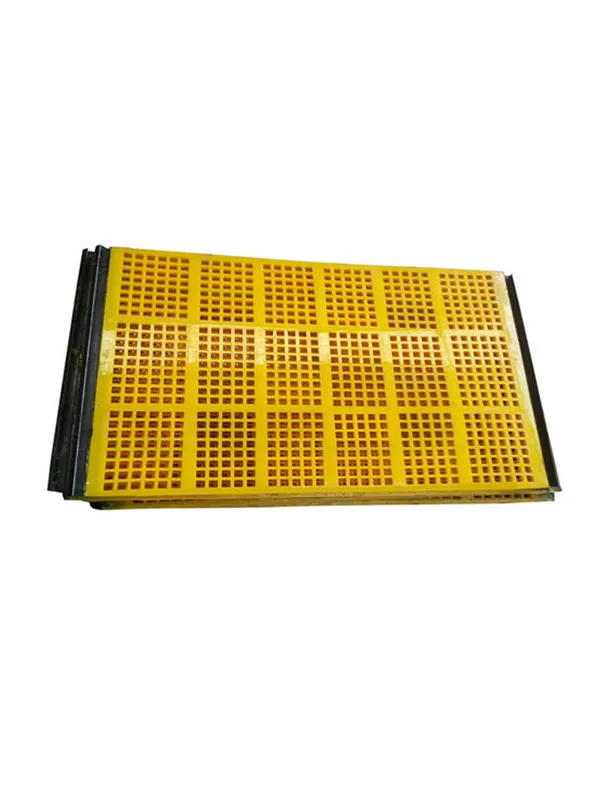

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.