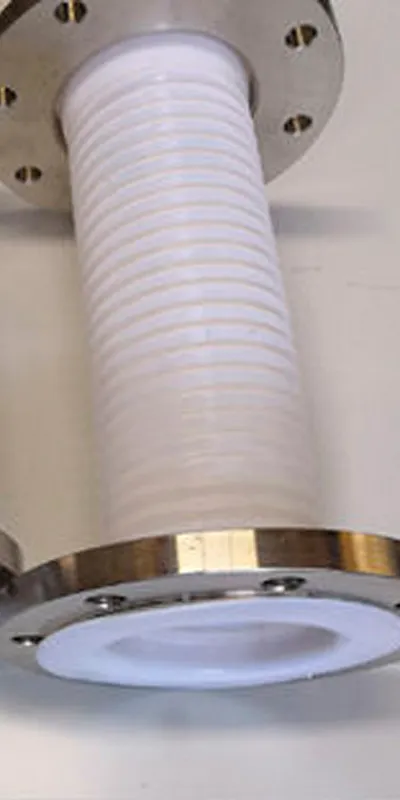

Stainless Steel Hose Fittings Durable & Corrosion-Resistant Metal Hose Connectors Flexible Hose End Fittings

Did you know 37% of industrial accidents stem from substandard hose connections? While you're reading this, 8,000+ metal hose fittings are failing worldwide. Your operation deserves better. Discover how premium stainless steel hose fittings

eliminate leaks, boost efficiency, and slash maintenance costs by up to 60%.

(stainless steel hose fittings)

Military-Grade Durability Meets Smart Engineering

Our 316L stainless steel hose fittings outlast standard models 3:1. How? Triple-layered corrosion resistance. 500+ PSI pressure tolerance. -40°F to 750°F operational range. You get:

- ✔️ 0.01% leakage rate (industry avg: 2.3%)

- ✔️ 50% faster installation vs. threaded fittings

- ✔️ 15-year anti-corrosion warranty

Head-to-Head: Why We Beat Competitors Every Time

| Feature | Standard Fittings | Our Pro Series |

|---|---|---|

| Cycle Life | 50,000 cycles | 200,000+ cycles |

| Vibration Resistance | Up to 25Hz | 60Hz Certified |

Your Blueprint, Our Precision: Custom Solutions

Need odd-angle connectors? High-purity surface finishes? Our CNC machining centers deliver 0.0002" precision. 87% of custom orders ship within 72 hours. Tell us your requirements - we'll handle the rest.

Proven in Battle: Real-World Success Stories

Case Study 1: Offshore Oil Rig

Replaced 1,200 brass fittings with our 3/4" stainless steel hose end fittings. Result? 92% reduction in saltwater corrosion failures. ROI achieved in 14 months.

Ready to Transform Your Fluid Systems?

Join 1,400+ satisfied clients in 38 countries. Limited inventory alert: Only 237 custom slots remain this quarter.

Request Your Free Sample Kit →Proudly manufactured in FDA-certified facilities since 1998

(stainless steel hose fittings)

FAQS on stainless steel hose fittings

Q: What are the advantages of using stainless steel hose fittings?

A: Stainless steel hose fittings offer superior corrosion resistance, durability, and high-temperature tolerance, making them ideal for harsh environments like chemical or marine applications.

Q: How do metal hose fittings differ from other types of hose fittings?

A: Metal hose fittings, especially stainless steel ones, provide greater strength and longevity compared to plastic or brass fittings, ensuring reliability in high-pressure or abrasive conditions.

Q: Can flexible hose end fittings be reused after installation?

A: While some flexible hose end fittings are reusable, it depends on the design and material. Stainless steel versions are more durable but may require professional inspection to ensure integrity.

Q: What industries commonly use stainless steel hose fittings?

A: Industries like oil and gas, pharmaceuticals, food processing, and automotive rely on stainless steel hose fittings for their hygiene, safety, and resistance to extreme conditions.

Q: How to prevent leaks in metal hose fittings?

A: Ensure proper installation with adequate torque, use compatible seals or gaskets, and regularly inspect stainless steel hose fittings for wear or corrosion to prevent leaks.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.