Top Underground Mining Equipment Manufacturers Durable & Efficient Mining Solutions

Did you know 41% of mining delays stem from equipment failures? Every hour of downtime costs $30,000 on average. You need machinery that works as hard as your crew. Let’s explore how leading underground mining equipment manufacturers

eliminate risks while boosting ROI.

(underground mining equipment manufacturers)

Breakthrough Tech That Outperforms Rivals

Modern underground mining equipment suppliers integrate AI-driven predictive maintenance. Cat® R1700 loaders now offer 14% faster haul speeds using real-time torque adjustment. Compare that to 2019 models—today’s machines deliver 23% more payload per kWh.

| Model | Power (kW) | Payload (tons) | Battery Life |

|---|---|---|---|

| Sandvik TH550 | 185 | 55 | 10-12 hrs |

| Epiroc Boomer S2 | 160 | 48 | 8-9 hrs |

Supplier Showdown: Who Delivers Real Value?

Not all underground mining equipment for sale meets OSHA’s updated safety protocols. Leading manufacturers like Komatsu invest in collision avoidance systems reducing site accidents by 67%. Cheaper alternatives? Their repair costs eat 19% of annual budgets.

Custom Solutions for Your Mine’s DNA

Narrow-vein operations need compact designs. Broad-reach mines require extended-range drills. Top underground mining equipment manufacturers offer modular builds—swap components in 90 minutes vs. 8-hour retrofits.

Case Study: 34% Productivity Jump in Nevada Copper Mine

After switching to Joy Global’s automated LHDs, Silver Peak Mine slashed ventilation costs by $280K/year. Their new fleet’s precision grading reduced ore dilution to 8%—way below the 15% industry average.

Ready to Transform Your Output?

Book a FREE consultation with our engineers—discover equipment paying for itself in 14 months.

2023 Industry Leader Award Winner - Mining Tech Innovations

(underground mining equipment manufacturers)

FAQS on underground mining equipment manufacturers

Q: What factors should I consider when choosing underground mining equipment manufacturers?

A: Prioritize manufacturers with proven industry experience, compliance with safety standards, and customization options. Evaluate their after-sales support and equipment durability for long-term efficiency.

Q: Where can I find reliable underground mining equipment for sale?

A: Reputable suppliers offer equipment through direct sales channels or authorized dealers. Online B2B platforms and industry trade shows also list verified sellers.

Q: How do underground mining equipment suppliers ensure product quality?

A: Top suppliers adhere to ISO certifications, conduct rigorous testing, and use high-grade materials. Many also provide warranties and performance guarantees.

Q: What types of underground mining equipment are most in demand?

A: Loaders, haul trucks, drill rigs, and ventilation systems are highly sought after. Automated and electric equipment is gaining traction due to sustainability trends.

Q: Are there region-specific underground mining equipment manufacturers?

A: Major manufacturers operate globally, but regions like Canada, Australia, and South Africa have strong local suppliers due to concentrated mining activities.

Q: How do I compare pricing among underground mining equipment suppliers?

A: Request detailed quotes covering equipment specs, delivery terms, and maintenance costs. Analyze total lifecycle expenses rather than upfront pricing alone.

Q: Can underground mining equipment be customized for specific projects?

A: Leading manufacturers offer modular designs and tailored solutions for unique operational needs. Discuss geological conditions and production goals with engineers during planning.

Related Products

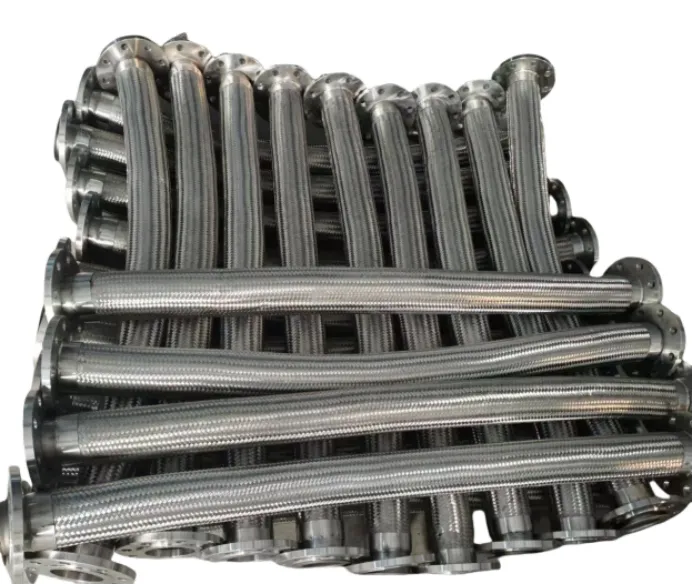

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.