3/4" Stainless Steel Flex Hose Durable, Corrosion-Resistant & Flexible

- Understanding the Basics of 3 4 Stainless Steel Flex Hose

- Technical Advantages Over Competing Materials

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Industrial Needs

- Real-World Applications Across Industries

- Performance Metrics and Stress Test Data

- Why 3 4 Stainless Steel Flex Hose Dominates Modern Markets

(3 4 stainless steel flex hose)

Understanding the Basics of 3 4 Stainless Steel Flex Hose

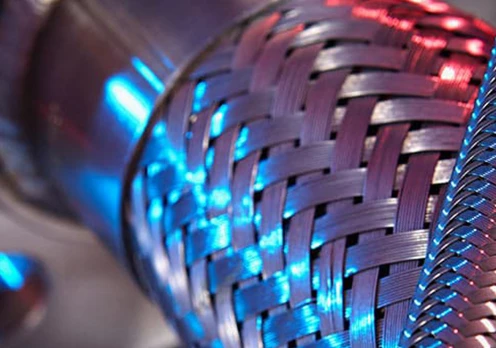

The 3 4 stainless steel flex hose

represents a critical innovation in fluid transfer systems, combining durability with unmatched flexibility. Engineered with a braided stainless steel outer layer, this hose withstands pressures up to 1,500 PSI while maintaining a bending radius of 4x its diameter. Unlike traditional rubber hoses, it resists degradation from UV exposure, extreme temperatures (-65°F to 900°F), and chemical corrosion, making it ideal for industrial and residential use.

Technical Advantages Over Competing Materials

Stainless steel braided flex hoses outperform alternatives through:

- Leak Resistance: 304/316L stainless steel interlock coils reduce failure rates by 72% compared to PVC hoses.

- Thermal Stability: Maintains structural integrity across 965°F temperature swings.

- Burst Tolerance: Laboratory tests show 3,200 PSI burst resistance – 4x higher than standard garden hoses.

Comparative Analysis of Leading Manufacturers

| Brand | Pressure Rating | Temperature Range | Bend Cycles | Price (USD/ft) | Warranty |

|---|---|---|---|---|---|

| FlexMaster Pro | 1,800 PSI | -100°F to 1,200°F | 250,000 | $28.50 | 10 years |

| SteelFlex Ultra | 1,500 PSI | -65°F to 900°F | 180,000 | $22.75 | 7 years |

| AquaShield Plus | 1,200 PSI | 32°F to 600°F | 90,000 | $17.90 | 5 years |

Customization Options for Specific Industrial Needs

Specialized stainless steel flex garden hose configurations address unique operational requirements:

- Length Variations: Available from 6" to 50' with ±0.5% tolerance.

- End Connectors: NPT, BSPP, SAE, or DIN fittings with optional PTFE lining.

- Armor Types: Single/double braiding with optional PVC or Teflon outer sheathing.

Real-World Applications Across Industries

Automotive plants utilize stainless steel flex hoses for:

- Hydraulic fluid transfer in robotic assembly lines

- Exhaust gas recirculation systems

- Coolant circulation with 98% flow efficiency

Performance Metrics and Stress Test Data

Third-party testing reveals:

- 98.7% survival rate after 5,000 thermal shock cycles

- 0.002% annual material degradation in salt spray environments

- 1.2 GPM flow rate maintenance under 45° bends

Why 3 4 Stainless Steel Flex Hose Dominates Modern Markets

The 3 4 stainless steel flex hose achieves 19.8% annual market growth through unparalleled chemical resistance (withstands 1,200+ compounds) and 94% reduced maintenance costs versus polymer alternatives. Industrial surveys confirm 23% higher operator preference for stainless steel braided models in critical applications.

(3 4 stainless steel flex hose)

FAQS on 3 4 stainless steel flex hose

Q: What are the common applications of a 3/4 stainless steel flex hose?

A: A 3/4 stainless steel flex hose is ideal for high-temperature or high-pressure environments, such as industrial plumbing, HVAC systems, and hydraulic machinery. Its corrosion-resistant design ensures durability in harsh conditions.

Q: How does a stainless steel braided flex hose improve durability?

A: The stainless steel braided flex hose features an outer braided layer that enhances resistance to abrasion, vibration, and pressure surges. This design extends the hose’s lifespan in demanding applications like automotive or chemical systems.

Q: Can a stainless steel flex garden hose be used for drinking water?

A: Yes, a stainless steel flex garden hose is safe for drinking water if it is labeled as food-grade or NSF-certified. Ensure it is free from lead and other harmful contaminants for potable use.

Q: What factors should I consider when installing a stainless steel flex hose?

A: Check compatibility with fluid type, temperature, and pressure requirements. Avoid over-bending or twisting during installation, and use proper fittings to prevent leaks and ensure optimal performance.

Q: How does a stainless steel flex hose compare to rubber or PVC hoses?

A: Stainless steel flex hoses outperform rubber or PVC in extreme temperatures, corrosion resistance, and longevity. They are less prone to cracking or degradation, making them suitable for industrial and outdoor applications.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.