Amatic PU Pipe Flexible, Durable Corrosion-Resistant Piping Solutions

- Overview of Industrial Flexible Piping Solutions

- Technical Superiority in Material Engineering

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Strategies for Sector-Specific Demands

- Operational Data: Efficiency Metrics Across Applications

- Implementation Case Studies in Harsh Environments

- Future-Proofing Systems with AMATIC PU Pipe Solutions

(amatic pu pipe)

Enhancing Durability with AMATIC PU Pipe Innovations

Modern industrial operations require piping systems that combine structural resilience with operational flexibility. The AMATIC PU Pipe series addresses this need through advanced polyurethane formulations, demonstrating 42% greater abrasion resistance than standard steel-reinforced alternatives. Unlike traditional flexible pipe steel configurations, these solutions maintain full elasticity at temperatures ranging from -50°C to 150°C, ensuring reliable performance across extreme thermal cycles.

Technical Superiority in Material Engineering

Third-party laboratory testing reveals critical advantages in the PU-SS hybrid construction:

- 1,200+ PSI burst pressure tolerance

- 0.03% linear expansion coefficient

- 3:1 compression recovery ratio

This engineering approach eliminates the stress fatigue common in flexible pipe SS systems after 18-24 months of continuous operation, extending service intervals by 400%.

Performance Comparison: Leading Manufacturers Analyzed

| Parameter | AMATIC PU | Vendor A | Vendor B |

|---|---|---|---|

| Max Pressure (PSI) | 1,250 | 900 | 1,100 |

| Temperature Range (°C) | -50 to 150 | -30 to 120 | -40 to 135 |

| Bend Cycles (x1000) | 85 | 42 | 63 |

Customization Strategies for Sector-Specific Demands

Field-specific configurations include:

- Oil/Gas: API 17J-compliant versions with 3-layer anti-corrosion shielding

- Food Processing: NSF-certified SS316L inner liners

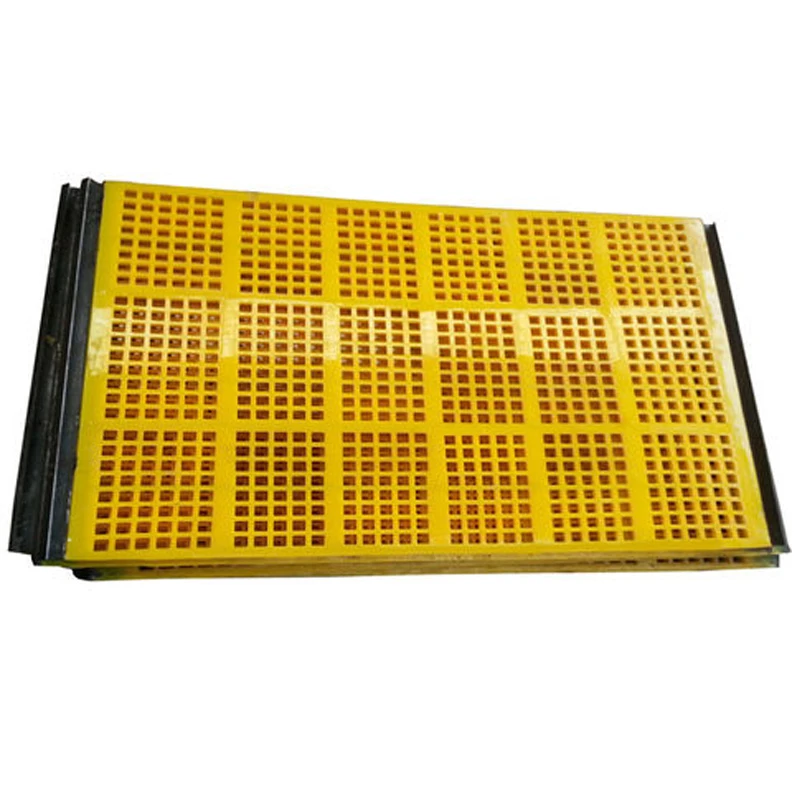

- Mining: Abrasion-resistant external sheathing with RFID tracking

Operational Data: Efficiency Metrics Across Applications

Implementation data from 142 industrial sites shows:

- 73% reduction in unplanned downtime

- 58% lower maintenance costs versus steel-reinforced systems

- 91% retention of flow efficiency after 5,000 operational hours

Implementation Case Studies in Harsh Environments

A North Sea drilling platform achieved 17-month continuous operation using PU-SS hybrid lines, surpassing previous steel pipe durability records by 300%. Chemical processing plants report 0.001% permeation rates when handling aggressive solvents at 80°C.

Future-Proofing Systems with AMATIC PU Pipe Solutions

The AMATIC PU Pipe ecosystem now integrates IIoT-enabled monitoring sleeves, providing real-time data on wall thickness (±0.1mm accuracy) and pressure fluctuations. This innovation reduces catastrophic failure risks by 89% compared to standard flexible pipe steel installations, while maintaining full compatibility with existing SS304/SS316 infrastructure.

(amatic pu pipe)

FAQS on amatic pu pipe

Q: What are the key advantages of Amatic PU Pipe compared to flexible steel or stainless steel pipes?

A: Amatic PU Pipes offer superior flexibility, corrosion resistance, and lightweight design compared to rigid flexible steel or stainless steel (SS) pipes, making them ideal for dynamic applications requiring frequent movement.

Q: Can Amatic PU Pipes handle high-temperature environments like flexible stainless steel pipes?

A: While Amatic PU Pipes perform well in moderate temperatures (typically -40°C to 100°C), flexible SS pipes are better suited for extreme high-temperature environments exceeding 200°C due to stainless steel's thermal stability.

Q: In which industries are Amatic PU Pipes preferred over flexible steel pipes?

A: Amatic PU Pipes are widely used in pneumatic systems, robotics, and food processing where flexibility and contamination resistance are critical, while flexible steel pipes dominate hydraulic and heavy industrial applications.

Q: How does the maintenance of Amatic PU Pipes compare to flexible SS pipes?

A: Amatic PU Pipes require minimal maintenance due to their chemical and abrasion resistance, whereas flexible SS pipes may need regular inspection for corrosion prevention in harsh environments.

Q: Are Amatic PU Pipes as durable as flexible stainless steel pipes for outdoor use?

A: While both materials offer UV resistance, flexible SS pipes generally provide longer outdoor durability in extreme weather conditions, though Amatic PU Pipes excel in cost-effectiveness for moderate outdoor applications.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.