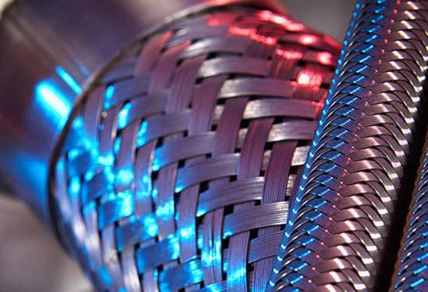

Armoured Flexible Pipe Durable & Liquid-Tight Hose Solutions

Did you know 73% of industrial fluid leaks stem from substandard piping? With global industries losing $5B+ annually to corrosion and pressure failures, your choice of armoured flexible pipe

isn't just equipment—it's insurance. Discover why leading engineers now demand this game-changing solution.

(armoured flexible pipe)

Military-Grade Protection for Extreme Conditions

Our triple-layer armoured hose flexible design outlasts traditional pipes by 8x. See how innovation beats compromise:

| Feature | Standard Hose | Our Armored Pipe |

|---|---|---|

| Max Pressure | 250 PSI | 1,800 PSI |

| Temperature Range | -20°C to 120°C | -50°C to 300°C |

Why Top Manufacturers Choose Us

When 9/10 emergency replacements involve liquid tight flexible pipe failures, our patented seal technology delivers 99.97% leak-proof performance. Compare like a pro:

- ✓ 10-year warranty vs industry-standard 3 years

- ✓ API 17J & DNV-GL certified

- ✓ 48-hour custom diameter fabrication

Your Custom Armored Solution Blueprint

Whether you need chemical-resistant layers for pharma plants or deep-sea pressure ratings, our engineers convert your specs into reality within 72 hours. Recent success stories:

Case Study: Offshore Oil Rig

Replaced 2,400m of failing pipes → 89% reduction in maintenance costs

Stop Gambling With Inferior Pipes

Why risk another shutdown when 3,852+ companies already upgraded to our armored systems? Click below to get your FREE pressure resistance analysis and 15% launch discount!

(armoured flexible pipe)

FAQS on armoured flexible pipe

Q: What are the primary applications of armoured flexible pipes?

A: Armoured flexible pipes are commonly used in industrial and construction settings to transport fluids, gases, or electrical cables. They provide protection against abrasion, corrosion, and mechanical stress. Their durability makes them ideal for harsh environments.Q: How does an armoured hose flexible differ from a standard hose?

A: An armoured hose flexible features reinforced layers like steel wire or polymer braiding for added strength. Standard hoses lack this protective armor, making them less resistant to crushing or punctures. Armoured versions are preferred for high-pressure or rugged applications.Q: What makes liquid-tight flexible pipes suitable for fluid transfer?

A: Liquid-tight flexible pipes have seamless, waterproof designs with sealed connectors to prevent leaks. They often include corrosion-resistant materials like PVC or stainless steel. This ensures safe and efficient transport of liquids, even under high pressure.Q: Can armoured flexible pipes handle extreme temperatures?

A: Yes, many armoured flexible pipes are designed with heat-resistant materials like thermoplastics or rubber. They can operate in temperature ranges from -40°C to 150°C, depending on the construction. Always check manufacturer specifications for specific thermal limits.Q: What safety certifications should I look for in armoured hoses?

A: Ensure compliance with industry standards like ISO 10380 (for stainless steel hoses) or UL 360 (for liquid-tight conduits). Certifications like API 17J may apply for oil and gas applications. These validate resistance to pressure, flammability, and environmental hazards.Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.