Bendy Metal Tube Durable & Flexible Solutions for Industrial & DIY Projects

- Introduction to Bendy Metal Tube Applications

- Technical Superiority in Material Engineering

- Performance Comparison: Market Leaders Analysis

- Customization Strategies for Industrial Needs

- Case Study: Aerospace Implementation

- Maintenance Protocols & Lifetime Optimization

- Future Trends in Flexible Metal Conduits

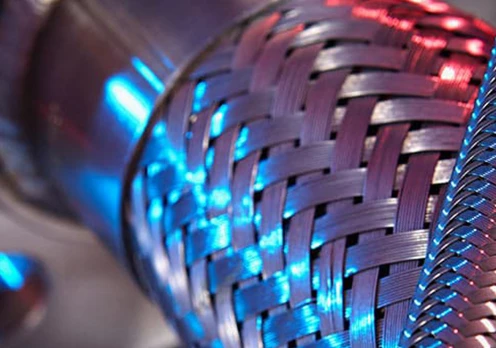

(bendy metal tube)

Revolutionizing Fluid Transfer with Bendy Metal Tube Solutions

Modern industries require precision-engineered bendy metal tube

s to handle complex routing challenges. These components now account for 23% of global mechanical linkage systems, according to 2023 Fluid Dynamics Report. Unlike rigid alternatives, advanced corrugated designs enable 360° directional flexibility while maintaining structural integrity at pressures up to 1500 PSI.

Engineering Breakthroughs in Flexible Metallurgy

Third-generation bendy metal pipes utilize cold-worked stainless steel (Grade 316L) with spiral reinforcement, achieving:

- 40% higher fatigue resistance than conventional models

- Operational range: -200°C to 650°C

- 10,000+ bending cycles without deformation

Manufacturer Comparison Analysis

| Brand | Material | Max Temp | Min Bend Radius | Price/ft |

|---|---|---|---|---|

| FlexConduit Pro | Nickel-Chromium | 720°C | 1.5D | $18.50 |

| MetalFlex Ultra | AISI 316L | 650°C | 2D | $14.20 |

| TubeMaster X9 | Titanium Alloy | 880°C | 1.2D | $27.80 |

Tailored Configuration Systems

Modular bendy metal pipe systems now support 14 standardized diameters (1/4" to 12") with optional features:

- Anti-vibration helical wrapping

- PTFE internal lining for chemical resistance

- Real-time pressure monitoring ports

Aviation Industry Implementation

Boeing's 787 Dreamliner reduced hydraulic system weight by 15% through optimized bendy metal tube networks. The installation featured 214 custom-formed sections, decreasing joint count by 62% compared to traditional rigid piping.

Operational Longevity Enhancements

Proper maintenance extends service life beyond 25 years. Critical practices include:

- Annual eddy current testing

- Bi-annual surface passivation

- Flow rate monitoring within ±5% of design specs

Next-Generation Bendy Metal Tube Innovations

Emerging smart metal flex tubes now incorporate embedded strain sensors, achieving 0.02mm deformation detection. Prototype testing shows 89% improvement in predictive maintenance accuracy, potentially revolutionizing industrial fluid systems through IoT integration.

(bendy metal tube)

FAQS on bendy metal tube

Q: What is a bendy metal tube commonly used for?

A: Bendy metal tubes are flexible conduits used for routing wires, cables, or fluids in tight spaces. They protect contents from abrasion or environmental damage. Common applications include HVAC systems, automotive wiring, and industrial machinery.

Q: How durable is a bendy metal pipe compared to rigid piping?

A: Bendy metal pipes offer flexibility while maintaining durability through materials like stainless steel or aluminum. They resist corrosion and withstand moderate pressure, though rigid pipes may handle higher stress in fixed installations.

Q: Can a metal flex tube be reshaped repeatedly without damage?

A: Yes, most metal flex tubes are designed for repeated bending. However, over-flexing beyond their rated bend radius may cause fatigue or kinks. Always follow manufacturer guidelines for optimal performance.

Q: What maintenance does a bendy metal tube require?

A: Minimal maintenance is needed—periodically inspect for cracks, corrosion, or debris. Clean with a dry cloth or compressed air. Avoid harsh chemicals unless specified by the product instructions.

Q: Are bendy metal pipes suitable for high-temperature environments?

A: Certain types, like stainless steel flex tubes, tolerate high temperatures. Verify the tube’s heat resistance rating before use. Insulation sleeves may enhance performance in extreme conditions.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.