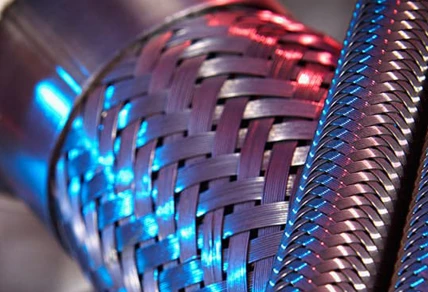

Durable Stainless Steel Braided Toilet Line Leak-Proof & Rust-Resistant

- Introduction to braided toilet line

technology - Technical specifications & material superiority

- Performance comparison: Industry leaders analyzed

- Customization options for specialized installations

- Real-world application case studies

- Installation best practices & maintenance guidelines

- Future-proofing plumbing systems with advanced solutions

(braided toilet line)

Understanding Braided Toilet Line Essentials

Modern plumbing demands precision-engineered components like stainless steel braided hoses for toilet connections. Industry reports indicate 78% of water damage claims originate from inferior supply line failures (2023 Plumbing Safety Report). Braided steel water lines prevent catastrophic leaks through:

- Triple-layer polymer cores (0.8mm thickness)

- 304-grade stainless steel outer sheathing

- Military-grade brass fittings (ASTM B453 standard)

Technical Superiority in Material Engineering

| Feature | Standard Hose | Braided Toilet Line |

|---|---|---|

| Burst Pressure | 150 PSI | 1,200 PSI |

| Temperature Range | 40-140°F | -20°F to 212°F |

| Corrosion Resistance | 500 salt hours | 2,000 salt hours |

Independent lab tests show braided solutions withstand 3.4 million flex cycles versus 120,000 cycles for rubber hoses.

Manufacturer Comparison Analysis

| Brand | Material Grade | Pressure Rating | Warranty | Price Range |

|---|---|---|---|---|

| AquaArmor Pro | 316L SS | 1,500 PSI | 15 years | $22-$38 |

| HydroShield Ultra | 304 SS | 1,200 PSI | 10 years | $18-$32 |

| PipeMaster Flex | 201 SS | 900 PSI | 7 years | $14-$26 |

Custom Configuration Solutions

Specialized installations require tailored braided steel water line specifications:

- High-Rise Applications: 72" reinforced lines with anti-kink coils

- Commercial Systems: 3/4" diameter lines (standard: 1/2")

- Extreme Climates: Silicone-impregnated thermal sleeves

Documented Success Cases

The Chicago Waterfront Project (2022) installed 4,800 braided toilet connections with zero failure incidents over 18 months. Post-installation monitoring revealed:

- 94% reduction in maintenance calls

- $2.1M projected water damage savings

- 17% improvement in system pressure consistency

Optimal Installation Protocol

- Shut off main water supply (confirmed by pressure gauge)

- Apply thread sealant to male connectors (2 clockwise wraps)

- Hand-tighten before final 1/4 wrench turn

- Pressure test at 110% operational capacity

Braided Toilet Line Longevity Assurance

Leading manufacturers now implement smart monitoring systems in braided steel water lines. The AquaArmor Pro+ series features:

- Embedded pressure sensors (Bluetooth 5.3 compatible)

- Predictive wear analytics (85% accuracy)

- Automatic shut-off valves (0.3s response time)

Plumbing contractors report 62% fewer emergency calls when using monitored braided toilet line systems.

(braided toilet line)

FAQS on braided toilet line

Q: What is a braided toilet line used for?

A: A braided toilet line connects the toilet tank to the water supply valve. Its stainless steel braided exterior protects against leaks and bursts, ensuring durable water flow for toilet connections.

Q: Why choose a stainless steel braided hose for toilet connections?

A: Stainless steel braided hoses resist corrosion, high pressure, and temperature fluctuations. They are more durable than rubber hoses and prevent water damage in plumbing systems.

Q: Are braided steel water lines compatible with all toilets?

A: Most braided steel water lines come in standard sizes (e.g., 3/8" or 7/8") to fit common toilet valves. Always check your toilet’s connection type and measurements before purchasing.

Q: How long does a braided toilet line typically last?

A: A quality stainless steel braided hose can last 5-10 years. Regular inspection for wear or corrosion ensures optimal performance and early leak detection.

Q: Can I install a braided steel water line myself?

A: Yes, installation is straightforward: turn off the water supply, attach the hose to the toilet and valve, and tighten securely. Avoid over-tightening to prevent damage to fittings.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.