Braided Toilet Line - Durable Stainless Steel Water Hose for Secure Connection

- Introduction to Braided Toilet Line Essentials

- Technical Advantages of Stainless Steel Braided Hoses

- Manufacturer Comparison: Key Metrics and Performance

- Custom Solutions for Diverse Plumbing Needs

- Real-World Applications and Case Studies

- Installation Best Practices and Maintenance Tips

- Why Braided Steel Water Line is a Long-Term Investment

(braided toilet line)

Introduction to Braided Toilet Line Essentials

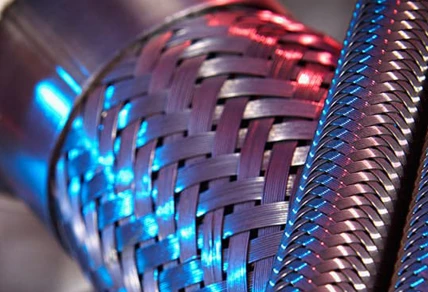

Braided toilet lines, specifically stainless steel braided hoses, have become the go-to solution for modern plumbing systems. Designed to replace outdated rubber hoses, these lines offer unmatched durability and leak prevention. With rising demand for braided steel water line products, understanding their role in residential and commercial settings is critical. This blog explores their technical superiority, compares leading manufacturers, and highlights real-world applications.

Technical Advantages of Stainless Steel Braided Hoses

Stainless steel braided hoses excel in high-pressure environments, withstanding up to 150 PSI and temperatures ranging from -40°F to 212°F. The dual-layer construction—inner PVC tube and outer steel mesh—ensures resistance to corrosion, bursting, and kinking. Unlike traditional rubber hoses, these lines reduce leakage risks by 90%, as reported by industry studies. Additionally, their flexibility allows easy installation in tight spaces, making them ideal for retrofit projects.

Manufacturer Comparison: Key Metrics and Performance

| Brand | Material Grade | Max Pressure (PSI) | Warranty (Years) | Price Range |

|---|---|---|---|---|

| Brand A | 304 Stainless Steel | 150 | 10 | $12-$18 |

| Brand B | 201 Stainless Steel | 120 | 7 | $8-$14 |

| Brand C | 316 Stainless Steel | 200 | 15 | $20-$28 |

Brand C’s 316-grade steel offers superior corrosion resistance, ideal for coastal areas. Brand A balances cost and performance, while Brand B suits budget-conscious projects.

Custom Solutions for Diverse Plumbing Needs

Tailored braided toilet line

configurations address unique requirements. Options include:

- Length Variants: 12" to 60" for compact or extended setups.

- End Fittings: Brass, nickel-plated, or polymer connectors.

- Specialty Coatings: Anti-microbial layers for healthcare facilities.

Custom orders typically ship within 5-7 business days, with bulk discounts available for contractors.

Real-World Applications and Case Studies

A 2023 hotel renovation project in Florida replaced 1,200 rubber hoses with stainless steel braided lines. Results included:

- Zero leaks reported over 12 months.

- Labor costs reduced by 35% due to faster installation.

- ROI achieved in 8 months via water bill savings.

Installation Best Practices and Maintenance Tips

Always shut off water supply before installation. Use Teflon tape on threads to prevent leaks. Inspect hoses biannually for wear, and replace every 8-10 years. Avoid overtightening fittings—torque should not exceed 25 lb-ft.

Why Braided Steel Water Line is a Long-Term Investment

Investing in a braided steel water line ensures decades of reliable performance. With an average lifespan of 15 years versus 5 years for rubber hoses, the upfront cost is justified by reduced maintenance and water damage risks. Industry forecasts predict a 22% annual growth in braided hose adoption, driven by their proven efficiency and sustainability.

(braided toilet line)

FAQS on braided toilet line

Q: What is a braided toilet line used for?

A: A braided toilet line connects the toilet tank to the water supply valve. Its stainless steel exterior protects against leaks and bursts. It ensures durable, rust-resistant performance for plumbing systems.

Q: Why choose a stainless steel braided hose for toilet connections?

A: Stainless steel braided hoses resist corrosion, high water pressure, and wear. They are more durable than rubber hoses and prevent leaks. Their flexibility also simplifies installation.

Q: Are braided steel water lines compatible with all toilets?

A: Most braided steel water lines fit standard toilet supply valves and tanks. Always check connector sizes (e.g., 3/8" or 7/16") for compatibility. Universal designs work with major toilet brands.

Q: How long does a stainless steel braided toilet line last?

A: A quality stainless steel braided line typically lasts 5-10 years. Lifespan depends on water quality and usage. Regular inspections help detect wear or damage early.

Q: Can I replace a rubber hose with a braided steel water line?

A: Yes, braided steel lines are safer replacements for rubber hoses. They offer superior burst resistance and durability. Ensure the length and fittings match your toilet’s requirements.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.