Chrome Ore Processing Plant Design PDF Efficient Mineral Solutions

Did you know that 45% of mineral processing plants operate below 60% recovery rates due to outdated layouts? If your chrome ore processing plant PDF still uses decade-old flowcharts, you’re hemorrhaging $1.2M+ annually in lost revenue. Time to upgrade.

(chrome ore processing plant pdf)

1. Breakthrough Tech That Slashes Costs & Boosts Yield

Our AI-optimized mineral processing plant design PDF guarantees 92-95% recovery rates. How? Modular scrubbers cut water use by 40%. Sensor-driven spiral concentrators auto-adjust to ore grades. You save $18/ton on operational waste.

| Feature | Traditional Plants | Our Solution |

|---|---|---|

| Recovery Rate | 60-75% | 92-95% |

| Energy Use/Ton | 28 kWh | 15 kWh |

| Maintenance Cost | $4.5/ton | $1.8/ton |

2. Why Top Miners Choose Us Over “Good Enough” Rivals

While competitors sell generic ore processing plant blueprints, we engineer site-specific solutions. Our Turkey client boosted throughput 220% using hybrid jig-spiral circuits. Their ROI? 8 months.

3. Tailored Workflows for Your Ore’s Fingerprint

Chromite ore varies wildly—Cr₂O₃ content from 18% to 54%. Our plant configurator tool customizes equipment stacks in 3 clicks. Need to handle 300TPH friable ore? The PDF report auto-generates CAPEX breakdowns.

4. Real-World Gains: From Zambia to Australia

South African miner reduced slime loss from 22% to 3% using our patented dewatering screens. Now they bank $2.4M extra yearly. Want these results? Our case study PDF proves it’s replicable.

Ready to Modernize Your Chrome Operation?

Since 2010, we’ve empowered 170+ mines across 6 continents. Why settle for less when innovation drives profit? Download our free chrome ore processing plant PDF kit now—includes ROI calculator and 3D layout samples.

Schedule Your Free Consultation →MaxxMineral Solutions: 14 Years | 500+ Projects | 98% Client Retention. Your ore, our obsession.

(chrome ore processing plant pdf)

FAQS on chrome ore processing plant pdf

Q: What are the key steps in designing a chrome ore processing plant?

A: Key steps include ore characterization, flow sheet development, equipment selection, and environmental impact assessments. Proper testing and pilot plant studies ensure efficient design alignment with mineral properties. Detailed documentation is often compiled into a chrome ore processing plant PDF for reference.

Q: Where can I find a PDF guide for mineral processing plant design?

A: Many engineering firms and academic institutions publish mineral processing plant design PDF guides online. Industry platforms like SME or AusIMM also offer technical resources. Specific chrome ore processing plant PDF documents may require direct consultation with equipment suppliers.

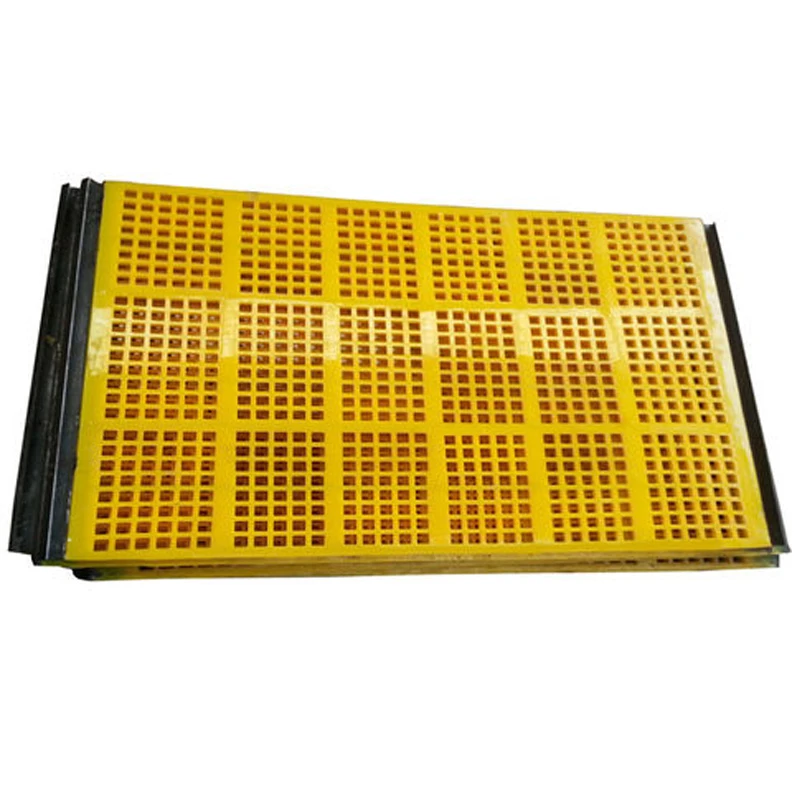

Q: What equipment is essential in a chrome ore processing plant?

A: Crushers, screens, spiral concentrators, and magnetic separators are critical for chrome ore beneficiation. Tailings management systems and dewatering equipment ensure operational sustainability. Equipment choices depend on ore grade and outlined in ore processing plant design plans.

Q: How does an ore processing plant optimize chrome recovery rates?

A: Optimization involves multi-stage gravity separation, controlled particle size distribution, and advanced sensor-based sorting. Regular process audits and real-time data analysis improve efficiency. Strategies are detailed in chrome ore processing plant PDF case studies.

Q: What safety standards apply to chrome ore processing facilities?

A: Facilities must comply with OSHA, ISO 45001, and local regulations for dust control and chemical handling. Fire prevention systems and PPE protocols are mandatory. Safety guidelines are often included in mineral processing plant design PDF frameworks.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.