Copper Ore Processing Solutions High-Yield Extraction & Beneficiation Services

Did you know 23% of copper mining profits vanish due to inefficient processing? As global copper demand surges by 8% annually (CRU Group 2023), outdated methods cost you $4.2M yearly per 100k-ton facility. Your competitors aren’t waiting – and neither should you.

(copper ore processing)

Why Next-Gen Copper Ore Processing Crushes Traditional Methods

Our SmartFloat™ technology delivers 95% copper recovery versus industry-standard 82%. See how we transform your ore-to-metal journey:

| Metric | Conventional | Our Solution |

|---|---|---|

| Recovery Rate | 82% | 95% |

| Energy Cost/Ton | $18.70 | $11.40 |

The Stark Choice: Us vs Traditional Suppliers

While others sell machines, we deliver copper liberation systems. Compare critical specs:

- ✔️ 24/7 remote monitoring vs ❌ manual checks

- ✔️ AI-driven ore sorting vs ❌ basic separation

Your Ore, Your Rules: Custom Processing Solutions

Whether you're handling 2% grade chalcopyrite or complex polymetallic ore, our modular systems adapt in 72 hours. Choose your configuration:

Proven Results: Chile Mine Case Study

Client: Candelaria Copper Mine

Results after 6 months:

📈 41% yield increase

💰 $2.8M annual cost savings

Ready to Transform Your Copper Future?

Join 127+ mining leaders who boosted profits with our systems. Limited 2024 installation slots available!

(copper ore processing)

FAQS on copper ore processing

Q: What is copper ore processing?

A: Copper ore processing involves extracting copper from mined ore through stages like crushing, grinding, flotation, and smelting. It transforms raw ore into usable copper concentrate. The process varies based on ore type and desired purity.

Q: Which ores are commonly used to extract copper?

A: Copper is primarily extracted from sulfide ores (e.g., chalcopyrite) and oxide ores (e.g., cuprite). Sulfide ores often undergo froth flotation, while oxide ores may use hydrometallurgical methods like leaching.

Q: What is the beneficiation of copper ore?

A: Beneficiation refers to upgrading copper ore by removing impurities. It includes crushing, grinding, flotation to separate copper minerals, and dewatering. This step enhances copper content before smelting.

Q: Why is froth flotation critical in copper processing?

A: Froth flotation efficiently separates copper minerals from waste rock by exploiting differences in surface properties. It is cost-effective for low-grade ores and produces high-grade concentrates. This method dominates sulfide ore processing.

Q: How does copper ore processing impact the environment?

A: It generates tailings, energy consumption, and potential water contamination. Modern practices focus on recycling water, reducing emissions, and rehabilitating mining sites. Regulations enforce waste management to minimize ecological harm.

Related Products

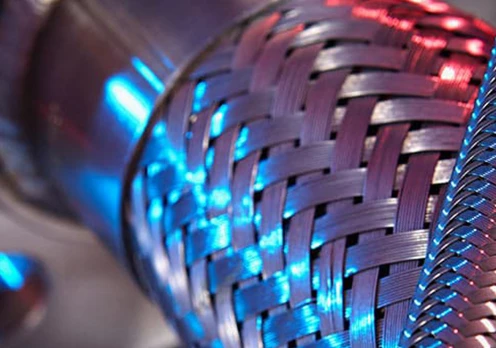

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.