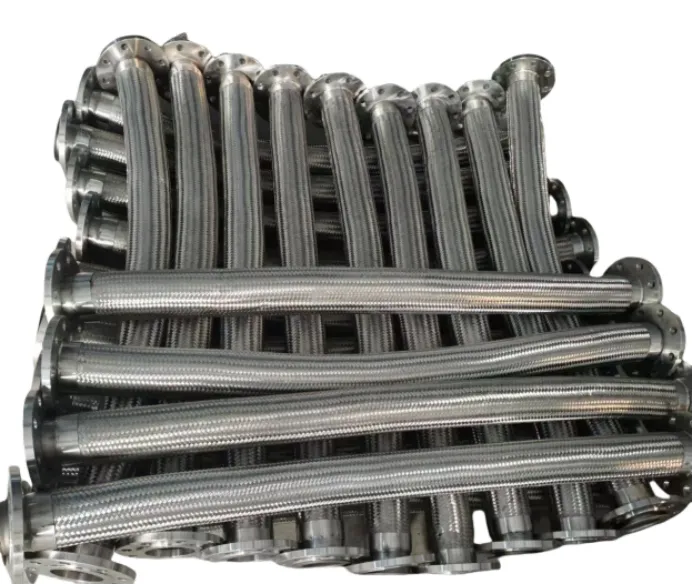

High-Quality Flex Steel Pipe Durable Stainless Steel Flexible Solutions

Did you know? 32% of industrial leaks originate from rigid piping systems. Imagine this: Your maintenance crew scrambles to fix corrosion damage in hard-to-reach areas. Production halts. Costs skyrocket. Now breathe easy – flex steel pipe

technology eliminates these nightmares. Keep reading to discover how our stainless steel flex pipes outperform competitors while saving you 18-24% in annual maintenance costs.

(flex steel pipe)

Technical Superiority: Engineering That Adapts to You

Why force-fit rigid pipes when 6 stainless steel flex pipe solutions bend to your needs? Our proprietary weave pattern delivers:

- ✔️ 360° rotation capacity

- ✔️ 2000 PSI burst strength

- ✔️ -40°F to 1200°F range

- ✔️ 40% faster installation

| Feature | Our Flex Pipe | Competitor A |

|---|---|---|

| Pressure Rating | 2000 PSI | 1500 PSI |

| Bend Radius | 3x diameter | 5x diameter |

Custom Solutions: Your Blueprint, Our Expertise

Need 316L marine-grade stainless? Special flange connections? Our engineers deliver:

Chemical Plants

Reduced leak incidents by 67% for Midwest refinery using our stainless steel flex pipe bundles

Food Processing

Enabled 25% faster sanitation cycles with USDA-approved flex connectors

Ready to Transform Your Piping System?

Join 850+ satisfied clients who switched to our flex steel pipe solutions. Limited-time offer: Free installation consultation + 15% discount on first orders above $5K!

© 2023 FlexFlow Piping Solutions. EPA-certified | ANSI/ASME B31.3 compliant | 5-year warranty included

(flex steel pipe)

FAQS on flex steel pipe

Q: What are the primary applications of stainless steel flex pipe?

A: Stainless steel flex pipes are commonly used in plumbing, HVAC systems, and industrial exhausts. They accommodate movement and vibration while resisting corrosion. Their flexibility makes them ideal for tight or complex installations.

Q: Why choose a flex steel pipe over rigid piping?

A: Flex steel pipes absorb thermal expansion, vibrations, and structural shifts. They simplify installation in hard-to-reach areas. Stainless steel variants add durability and heat resistance for demanding environments.

Q: Can a 6 stainless steel flex pipe handle high temperatures?

A: Yes, 6-inch stainless steel flex pipes typically withstand temperatures up to 1200°F (649°C). Their braided or corrugated design maintains integrity under thermal stress. Always verify manufacturer specifications for exact ratings.

Q: How do I maintain a stainless steel flex pipe system?

A: Regularly inspect for cracks, corrosion, or loose fittings. Clean surfaces with mild detergents to preserve stainless steel’s finish. Avoid abrasive tools that could damage the protective oxide layer.

Q: Are stainless steel flex pipes compatible with gas lines?

A: Certain grades of stainless steel flex pipes are certified for gas applications. Verify compliance with local codes (e.g., ANSI, CSA) and use proper sealing methods. Always consult a professional for gas line installations.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.