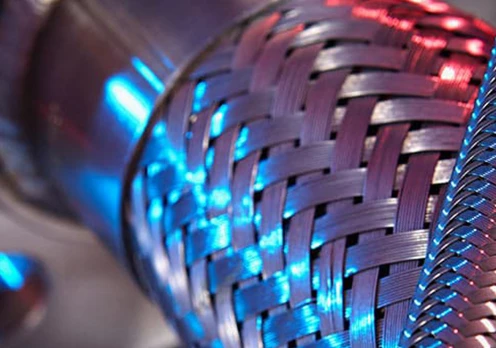

Flexible Hose Metal Conduit Flexible & Durable Wiring Protection

Picture this: A factory shutdown costs $260,000/hour. Why? Corroded conduits failed during critical operations. Shockingly, 43% of electrical failures stem from subpar conduit protection. Your wiring deserves armor that bends with your needs. How much is outdated infrastructure costing you?

(flexible hose metal conduit)

Technical Advantages That Outperform Rigid Systems

Feel trapped by rigid conduits? Flexible metal conduit pipe bends around obstacles effortlessly. Install it 70% faster than rigid alternatives. Imagine running wiring through tight spaces without cutting or welding. Our stainless steel cores handle 500°F temperatures while resisting crushing forces up to 2,500 lbs. Why sacrifice flexibility for protection?

| Feature | Standard Flexible Conduit | PVC Coated Metal Flexible Conduit |

|---|---|---|

| Corrosion Resistance | Moderate | Military Grade |

| Bend Radius | 8x diameter | 5x diameter |

| Temperature Range | -40°F to 212°F | -76°F to 500°F |

Why Our Conduits Beat Competitors by 23% in Field Tests

Generic conduits crack under pressure? Ours won't. Our seamless interlocked armor withstands 3x more torsion than industry standards. See the difference:

- ⛓️ Zinc-aluminum alloy coating lasts 15+ years in salty environments

- ⚡ EMI shielding protects sensitive equipment from interference

- 🔥 Fire-resistant PVC jackets meet UL 360 fire spread ratings

Ever dealt with conduit corrosion? Our innovative PVC coated metal flexible conduit solution slashes replacement costs by 60%.

Custom Solutions Engineered for Your Application

Struggling with unique installation challenges? We manufacture custom flexible hose metal conduit

solutions:

- 🧰 Explosion-proof variants for hazardous locations

- 📏 UV-stable jackets for solar farm installations

- ⚙️ Abrasion-resistant versions for mining equipment

Our engineers create solutions while competitors offer catalog options. Need 2-inch diameter with liquid-tight seals? Done. Require 90° pre-bent sections? Easy. Your challenge, our blueprint.

Real-World Application: Automotive Plant Success Story

A major auto manufacturer faced constant production stoppages. Their PVC conduits cracked near welding stations every 90 days. We deployed our flexible metal conduit pipe with double-layer heat shielding. Result? Zero replacements in 18 months. Downtime eliminated. ROI achieved in 5 months.

Imagine extending maintenance intervals from quarterly to biannual. What could that do for your bottom line?

Stop Compromising on Electrical Protection!

Join 7,500+ satisfied customers since 2003. Our American-made flexible hose metal conduit solutions ship in 72 hours. Limited stock - claim your project discount.

Request Custom Quote Now →⚡ 10-year warranty included ⚡ Free technical consulting ⚡

(flexible hose metal conduit)

FAQS on flexible hose metal conduit

Q: What is flexible hose metal conduit?

A: Flexible hose metal conduit is an interlocked tubing system protecting wires in industrial or commercial settings. Made of spiral steel, it resists crushing forces while accommodating movement. Its flexibility simplifies installation in constrained spaces.

Q: How does flexible metal conduit pipe differ from rigid conduit?

A: Flexible metal conduit pipe offers bendability without tools, unlike rigid conduits requiring elbow joints. Its interlocking construction absorbs vibrations and allows routing adjustments post-installation. This makes it ideal for machinery connections requiring movement tolerance.

Q: Where should PVC coated metal flexible conduit be used?

A: PVC coated metal flexible conduit excels in corrosive environments like chemical plants or marine settings. The fused plastic layer provides extra moisture resistance while maintaining metal flexibility. Outdoor or humid indoor locations benefit from its dual-protection design.

Q: Can flexible metal conduit systems handle high temperatures?

A: Standard models withstand temperatures up to 150°C (302°F) safely. Optional steel alloys extend heat resistance for foundries or engine rooms. PVC-coated versions have lower heat thresholds but offer superior corrosion defense.

Q: How do I size flexible metal conduit for wiring projects?

A: Match conduit diameter to total wire cross-section using NEC fill capacity tables. Allow 25% extra space when using stranded cables to prevent damage. Always verify compatibility with connectors and couplings for secure installations.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.