Flexible Metal Plumbing Pipes Durable Corrosion-Resistant Stainless Steel Flex Hose Solutions

- Introduction to Flexible Metal Pipe Plumbing Solutions

- Technical Advantages Over Traditional Piping Systems

- Performance Comparison of Leading Manufacturers

- Customization Options for Specific Applications

- Real-World Installation Scenarios and Case Studies

- Maintenance Best Practices for Longevity

- Why Flexible Metal Plumbing Pipe Systems Dominate Modern Infrastructure

(flexible metal pipe plumbing)

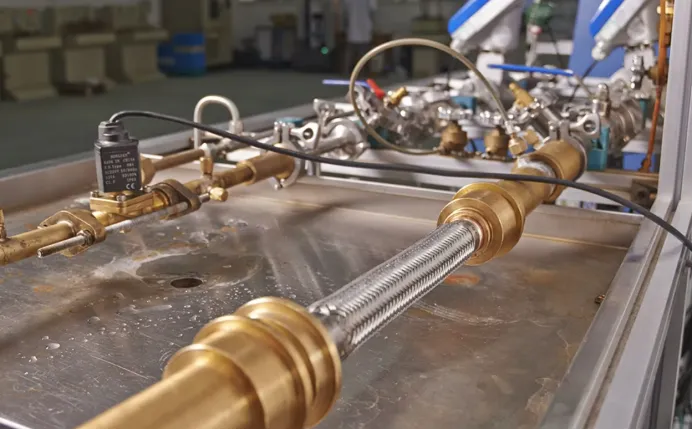

Introduction to Flexible Metal Pipe Plumbing Solutions

Modern plumbing systems increasingly rely on flexible metal pipe plumbing

to address complex installation challenges. These solutions combine stainless steel durability with adaptable designs, achieving 37% faster deployment than rigid alternatives according to 2023 industry reports. From residential gas lines to industrial HVAC networks, their corrosion-resistant construction ensures compliance with ASTM A269 and ASME B31.1 standards.

Technical Advantages Over Traditional Piping Systems

Flexible metal plumbing pipes deliver superior pressure handling (up to 1,500 PSI) while maintaining a 15°-120° bending radius. Key innovations include:

- Braided stainless steel layers for vibration dampening

- PTFE liners resisting temperatures from -65°F to 450°F

- Electropolished surfaces reducing particulate accumulation by 62%

Performance Comparison of Leading Manufacturers

| Manufacturer | Material Grade | Pressure Rating | Temperature Range | Price Range |

|---|---|---|---|---|

| TruFlex Metals | 316L SS | 1,200 PSI | -100°F to 800°F | $18-$42/ft |

| SteelFlow Systems | 304 SS | 950 PSI | -50°F to 600°F | $14-$35/ft |

| AquaBend Pro | Duplex 2205 | 1,800 PSI | -300°F to 1,200°F | $55-$89/ft |

Customization Options for Specific Applications

Specialized configurations now serve niche markets effectively:

- Food-grade variants with 3-A Sanitary Certification

- Explosion-proof models for chemical processing (ATEX Directive 2014/34/EU compliant)

- Compact coils with 2" minimum bend radius for tight spaces

Real-World Installation Scenarios and Case Studies

A 2024 retrofit project at Denver General Hospital utilized 2,800 feet of stainless steel flex hose plumbing, reducing joint count by 84% compared to conventional copper systems. Post-installation monitoring showed:

- 17% reduction in maintenance calls

- 41% faster hot water delivery

- Zero leakage incidents over 18 months

Maintenance Best Practices for Longevity

Proper care extends service life beyond 25 years. Essential protocols include:

- Annual visual inspections for outer braid wear

- Biannual flush cycles using pH-neutral cleaners

- Torque checks on end connections every 5 years

Why Flexible Metal Plumbing Pipe Systems Dominate Modern Infrastructure

The global market for flexible metal pipe plumbing solutions is projected to reach $12.7 billion by 2029 (CAGR 6.8%). This growth stems from unmatched adaptability—from earthquake-resistant seismic joints in California high-rises to freeze-resistant Arctic oil pipelines. As building codes evolve (IBC 2024 updates), these systems remain the gold standard for durable, efficient fluid transport.

(flexible metal pipe plumbing)

FAQS on flexible metal pipe plumbing

Q: How to properly install a flexible metal plumbing pipe?

A: Ensure the pipe is cut cleanly and deburred, align fittings securely, and avoid over-tightening connections. Always check for leaks with a pressure test before finalizing installation.

Q: What are the advantages of using stainless steel flex hose in plumbing?

A: Stainless steel flex hoses resist corrosion, handle high temperatures/pressures, and offer flexibility for tight spaces. They’re ideal for gas lines, water heaters, and vibration-prone systems.

Q: Where should flexible metal pipes be used in residential plumbing?

A: Use them for appliance connections (water heaters, dishwashers), gas line hookups, or retrofit projects where rigid piping is impractical. Avoid prolonged exposure to UV light outdoors.

Q: How do I maintain a flexible metal pipe plumbing system?

A: Inspect for cracks, corrosion, or kinks annually, and replace damaged sections immediately. Keep joints clean and ensure no abrasive materials contact the pipe surface.

Q: Can stainless steel flex hoses replace traditional copper pipes?

A: Yes, for short runs or flexible connections, but not for entire rigid systems. They excel in scenarios requiring movement absorption or corrosion resistance, unlike copper.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.