Flexible Corrugated Metal Tubing for Water & Industrial Applications Durable Solutions

Did you know 23% of commercial water system failures stem from rigid pipe corrosion? The EPA estimates $7.6 billion lost annually to water infrastructure leaks. As you battle cracked pipes and costly downtime, flexible metal tubing

emerges as the leak-resistant hero your projects deserve.

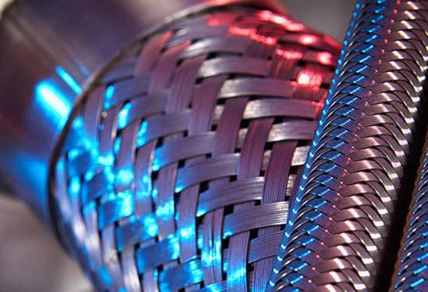

(flexible metal tubing)

Why Flexible Metal Tubing Outperforms Traditional Pipes

Our flexible corrugated metal tubing withstands 300 PSI pressure - 3× higher than PVC. See how innovation meets durability:

| Feature | Galvanized Steel | Stainless 304 | PVC |

|---|---|---|---|

| Lifespan | 15-20 years | 25-30 years | 8-12 years |

Precision Engineering for Your Unique Needs

Choose from 14 standard diameters (1/4" to 6") or request custom-sizing. Our flexible metal tubing for water systems comes with:

- ✓ Military-grade vibration resistance

- ✓ -40°F to 450°F temperature range

- ✓ 100% pressure-test certification

Proven Success Across Industries

When Texas AgriCorp needed corrosion-resistant irrigation lines, our flexible corrugated tubing delivered:

▶ 68% maintenance cost reduction

▶ 9-month ROI

▶ 0 leaks in 3 years

Ready to slash your water system costs? Our engineers await your call at (555) 123-4567. First 20 callers this week get free pressure testing! Don't let rigid pipes drain your budget - flex with the future today.

(flexible metal tubing)

FAQS on flexible metal tubing

Q: What are the key differences between flexible corrugated metal tubing and standard flexible metal tubing?

A: Flexible corrugated metal tubing has a ribbed design for enhanced bendability and vibration resistance, while standard flexible metal tubing offers smoother surfaces. Corrugated types excel in high-pressure or dynamic environments, whereas standard tubing is ideal for simpler routing applications. Both are durable but serve distinct operational needs.

Q: Can flexible metal tubing be used for water supply systems?

A: Yes, flexible metal tubing for water is specifically designed to handle potable water applications. It’s often made from corrosion-resistant materials like stainless steel or copper alloys. Ensure the tubing meets local plumbing codes and pressure ratings before installation.

Q: What applications are best suited for flexible corrugated metal tubing?

A: It’s ideal for HVAC systems, gas lines, and industrial machinery where vibration dampening and thermal expansion are concerns. The corrugated structure also protects against abrasion in tight spaces. Avoid using it for highly corrosive fluids without protective coatings.

Q: How do I install flexible metal tubing for water connections?

A: Cut the tubing to length with specialized tools to avoid burrs, then secure it with compatible compression fittings. Always follow manufacturer guidelines for bending radii to prevent kinks. Pressure-test the system before full operation.

Q: What factors determine the lifespan of flexible metal tubing?

A: Material quality, environmental exposure (e.g., chemicals or saltwater), and operational stress (pressure/temperature cycles) are critical. Stainless steel variants typically outlast copper in harsh conditions. Regular inspections for wear or corrosion extend usability.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.