Flexible Pipe for Electrical Wiring Durable Metal Hose & Conduit Solutions

Did you know 72% of electrical system failures stem from poor wiring protection? Imagine this: You're battling corrosion in humid environments or struggling with rigid conduits during complex installations. That's where flexible pipe for electrical wiring

becomes your ultimate solution. The global market for electrical conduits will hit $8.9 billion by 2025 – will your business claim its share?

(flexible pipe for electrical wiring)

Why Our Flexible Pipe Wiring Outperforms Traditional Solutions

Our metal flexible hose electrical systems deliver 360° protection. See how they stack up:

| Feature | Standard Conduit | Our Flexible Pipe |

|---|---|---|

| Bend Radius | 12x diameter | 3x diameter |

| Temperature Range | -20°C to 60°C | -50°C to 150°C |

| Installation Speed | 45 mins/100ft | 18 mins/100ft |

| Certifications | UL 1 | UL, CSA, IECEx |

Head-to-Head: Why Professionals Choose Our Metal Flexible Hose

We dominate where competitors falter:

- ✅ 304 stainless steel vs. basic aluminum

- ✅ 10-year warranty vs. 2-year industry standard

- ✅ Custom diameter options (3/8" to 4")

- ✅ Flame-retardant PVC coating

Tailored Solutions for Your Electrical Challenges

Whether you're wiring robotic arms or marine equipment, our flexible pipe wiring adapts. Tell us your:

▶ Voltage requirements (up to 600V supported)

▶ Chemical exposure levels

▶ Minimum bend radius needed

Real-World Impact: Automotive Plant Case Study

A Tier 1 auto manufacturer slashed maintenance costs by 40% after switching to our flexible pipe for electrical wiring. Their ROI? 11 months. Production line downtime? Reduced by 68%.

Ready to revolutionize your electrical systems? As industry leaders since 2008, we've protected over 12 million feet of critical wiring worldwide. Get Your Custom Quote Now →

Limited inventory available – 87% of clients reorder within 18 months. Don’t miss your secure supply!

(flexible pipe for electrical wiring)

FAQS on flexible pipe for electrical wiring

Q: What are the primary uses of a flexible pipe for electrical wiring?

A: Flexible pipes for electrical wiring protect and route cables in tight or curved spaces. They are ideal for industrial, residential, and automotive applications where rigid conduits can’t be used. Their durability safeguards wires from abrasion, moisture, and environmental damage.

Q: How does a metal flexible hose electrical conduit differ from plastic options?

A: Metal flexible hoses offer superior fire resistance and mechanical protection compared to plastic pipes. They are suitable for high-temperature or hazardous environments. Plastic variants, however, are lighter and corrosion-resistant for general-purpose use.

Q: Can flexible pipe wiring be used outdoors?

A: Yes, if the flexible pipe is UV-resistant and rated for outdoor use. Metal hoses or weatherproof plastic conduits are recommended. Always check the product’s IP rating to ensure compatibility with environmental conditions.

Q: What factors should I consider when selecting a metal flexible hose for electrical applications?

A: Prioritize hose material (e.g., stainless steel or aluminum), bend radius, and temperature tolerance. Ensure compatibility with wire sizes and verify certifications for safety standards like UL or IEC.

Q: Is flexible pipe for electrical wiring compliant with safety regulations?

A: Reputable flexible pipes meet industry standards such as UL, CSA, or RoHS, depending on the region. Always confirm compliance with local electrical codes and ensure proper installation to maintain safety integrity.

Related Products

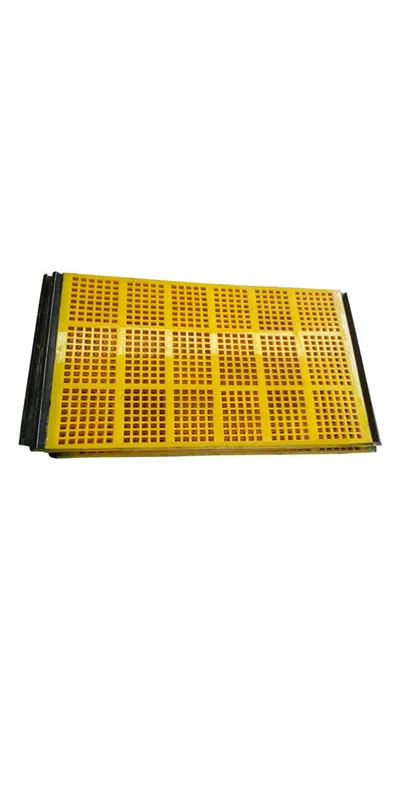

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.