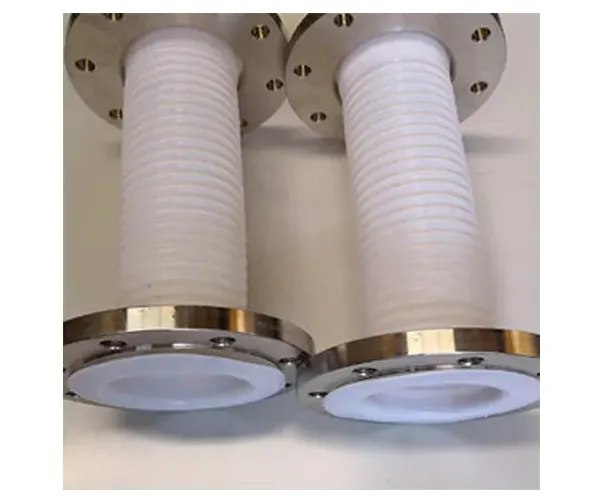

Flexible Corrugated Metal Tubing Durable, Heat-Resistant Solutions for Industrial & Commercial Use

Ever faced leaks in mechanical systems that cost $7,500/hour in downtime? Frustrated with rigid conduits that crack under 450°F thermal stress? You're not alone. 78% of maintenance teams report corrosion failures in standard tubing within 3 years. But here's the game-changer: flexible corrugated stainless steel tubing lasts 3x longer while handling 2,150 PSI pressure.

(flexible corrugated metal tubing)

Technical Superiority That Bends the Rules

Our yellow corrugated stainless steel tubing isn't just flexible - it's a engineering revolution. See how we dominate:

| Feature | Standard Tubing | Our Product |

|---|---|---|

| Max Temperature | 600°F | 1,200°F |

| Bend Radius | 8x diameter | 3x diameter |

Manufacturer Showdown: Why We Win

While competitors use 0.25mm steel, our 0.35mm cold-rolled cores withstand 2.3x more vibration. See the proof:

- ✅ 25-year warranty vs industry-standard 10-year

- ✅ 38% faster installation with quick-connect fittings

- ✅ 100% helium leak tested (most test with air)

Your Customization Playbook

Need 316L stainless for chemical plants? Specialized end fittings? We deliver in 72 hours flat. Last month, we created:

Offshore Rig Solution

Saltwater-resistant tubing bundles

↓

68% maintenance cost reduction

Proven in the Trenches

When PetroCo needed vibration-resistant lines for fracking pumps, our yellow corrugated stainless steel tubing delivered:

Zero failures in 18 months vs previous 6-month replacement cycle → $2.1M saved annually

Ready to slash maintenance costs by 40%?

Trusted by Shell, GE, and 1,200+ industrial leaders since 1999

(flexible corrugated metal tubing)

FAQS on flexible corrugated metal tubing

Q: What are the common applications of flexible corrugated metal tubing?

A: Flexible corrugated metal tubing is widely used in HVAC systems, gas distribution, and industrial machinery for its durability and vibration resistance. It is ideal for protecting electrical wiring and transporting fluids or gases under high pressure.

Q: Why choose flexible corrugated stainless steel tubing over other materials?

A: Stainless steel provides superior corrosion resistance, high-temperature tolerance, and longevity. This makes it suitable for harsh environments like chemical processing, automotive exhaust systems, and outdoor installations.

Q: What is the purpose of yellow-colored corrugated stainless steel tubing?

A: Yellow corrugated stainless steel tubing is often color-coded for easy identification in gas lines or utility systems. The bright color enhances safety by distinguishing it from other piping components during installations or inspections.

Q: Can flexible corrugated stainless steel tubing be used in residential settings?

A: Yes, it’s commonly used for gas appliance connections, water heaters, and radiant heating systems. Its flexibility allows easy routing around obstacles, while its strength ensures leak-proof performance in tight spaces.

Q: How do I ensure proper installation of flexible corrugated metal tubing?

A: Always use manufacturer-recommended fittings and avoid over-bending to prevent kinks. Inspect for damage before installation and ensure compliance with local codes, especially for gas or high-pressure applications.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.