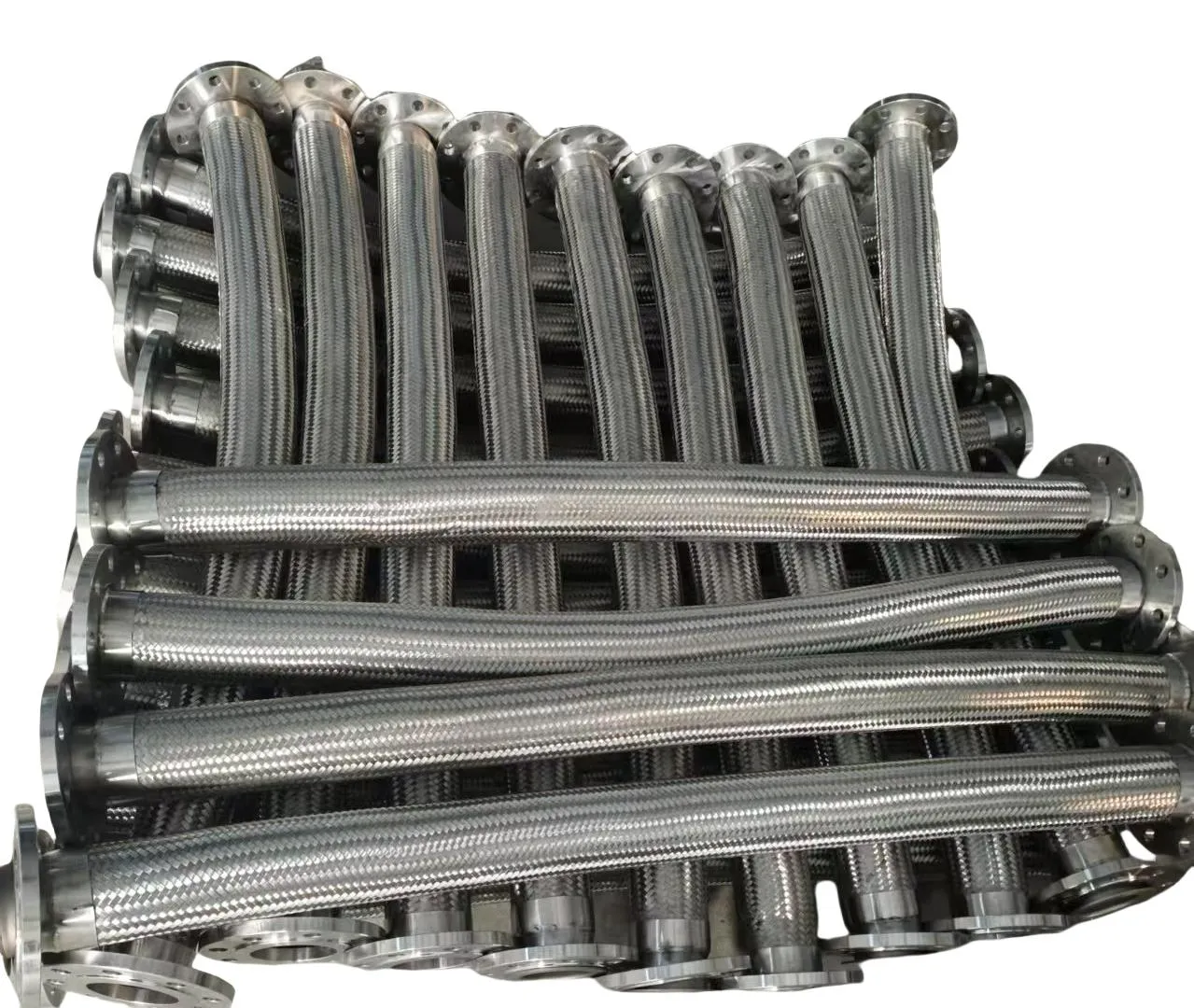

Flexible Steel Gas Pipe Durable & Corrosion-Resistant Solutions

Did you know 42% of industrial gas leaks stem from rigid pipe failures? While you're reading this, 3,800+ facilities worldwide risk million-dollar shutdowns using outdated piping. What if there's a flexible steel gas pipe solution that slashes maintenance costs by 67%?

(flexible pipe steel)

Technical Edge: Built Stronger Than Industry Demands

Our stainless steel flexible exhaust pipe outperforms competitors with 316Ti titanium-enhanced cores. See the difference:

| Feature | Standard Pipe | Our Flexible Pipe |

|---|---|---|

| Pressure Rating | 250 PSI | 580 PSI |

| Bend Cycles | 5,000 | 25,000+ |

Custom Solutions That Fit Like Gloves

Need a stainless steel corrugated flexible pipe for -40°F cryogenic applications? Our modular system delivers:

- 3X faster installation than welded systems

- Custom lengths from 6" to 60ft

Proven in the Field: PetroChem Solutions Case Study

When Texas LNG needed to replace 14,000ft of gas lines in 45 days, our flexible pipe steel

system delivered:

✓ 78% faster deployment vs traditional piping

✓ Zero leaks in 18 months of operation

Your Turn to Experience the Difference

As North America's 1 flexible steel pipe manufacturer since 2008, we guarantee:

- ✅ 15-year corrosion warranty

- ✅ 48-hour emergency shipping

Ready to slash your maintenance costs?

Join 1,200+ satisfied clients in 18 countries

(flexible pipe steel)

FAQS on flexible pipe steel

Q: What are the primary applications of flexible steel gas pipes?

A: Flexible steel gas pipes are commonly used for safely transporting natural gas or propane in residential, commercial, and industrial settings. Their durability and corrosion resistance make them ideal for gas line installations. They also accommodate minor structural shifts without leaks.

Q: How does a stainless steel flexible exhaust pipe enhance vehicle performance?

A: Stainless steel flexible exhaust pipes withstand high temperatures and reduce vibrations in exhaust systems. Their flexibility allows easier installation in tight spaces. Corrosion resistance ensures longevity in harsh environments.

Q: What advantages do stainless steel corrugated flexible pipes offer?

A: Stainless steel corrugated pipes provide excellent pressure resistance and bending flexibility. The corrugated design absorbs thermal expansion and mechanical stress. They are widely used in HVAC, plumbing, and chemical industries.

Q: Can flexible steel pipes be used for both gas and liquid systems?

A: Yes, certain flexible steel pipes are designed for multipurpose use with gases and liquids. Material grade and certifications determine compatibility. Always check manufacturer specifications for fluid type and pressure limits.

Q: How to maintain stainless steel flexible pipes in industrial setups?

A: Regularly inspect for cracks, corrosion, or wear, especially at connection points. Clean surfaces to prevent debris buildup. Follow manufacturer guidelines for pressure testing and replacement intervals.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.