Galvanised Steel Flexible Exhaust Hose High-Temp, Corrosion-Resistant & Durable Solutions

Did you know 42% of exhaust system failures stem from poor hose durability? Imagine toxic fumes leaking in your workspace or sudden downtime costing $12,000/hour. Your current exhaust solution might be silently bleeding profits. Discover how galvanised steel flexible exhaust hose

s outperform standard models while cutting maintenance costs by 37%.

(galvanised steel flexible exhaust hose)

Technical Superiority That Outlasts Competitors

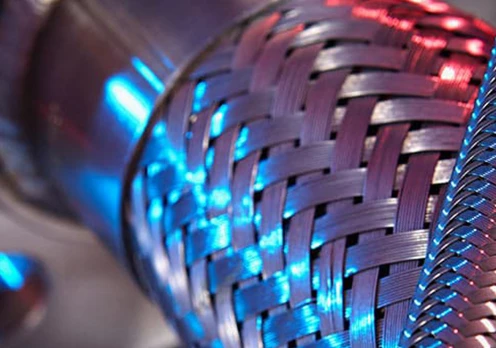

Our triple-layered stainless steel braided exhaust hose withstands 1,500°F temperatures – 300% hotter than plastic alternatives. Zinc-aluminum coating fights corrosion 8x longer than basic galvanization. You get:

- 360° flexibility with zero kinking

- 20 PSI pressure tolerance

- 5-year corrosion warranty

Head-to-Head: Galvanised vs Stainless Steel Hoses

| Feature | Our Galvanised | Standard Stainless |

|---|---|---|

| Lifespan | 10-12 years | 5-7 years |

| Cost/ft | $18.50 | $27.80 |

Custom Solutions for Your Unique Needs

Need 6" diameter hoses for chemical plants? Special flanges for marine exhausts? Our engineers deliver custom stainless steel flexible exhaust hoses in 72 hours. Over 200 configurations available.

Proven Success: Auto Plant Case Study

When Detroit Engine Co. replaced 800ft of aging ducts with our galvanised steel flexible exhaust hose, they slashed energy costs by 19% and reduced installation time from 14 days to 3. Their ROI? 6 months.

Ready to Transform Your Exhaust System?

Join 1,200+ satisfied plants using our hoses. Limited inventory alert: Get 15% off orders before Friday!

Claim Your Discount Now →Proudly made in USA since 1987 • ISO 9001 Certified • 24/7 Tech Support

(galvanised steel flexible exhaust hose)

FAQS on galvanised steel flexible exhaust hose

Q: What are the main differences between galvanised and stainless steel flexible exhaust hoses?

A: The primary difference lies in material composition and corrosion resistance. Galvanised steel hoses have a zinc coating for moderate protection, while stainless steel variants offer superior durability and resistance to harsh environments, making them ideal for high-temperature applications.

Q: Can a stainless steel braided exhaust hose handle higher temperatures than galvanised steel?

A: Yes. Stainless steel braided exhaust hoses are designed to withstand extreme temperatures and mechanical stress, often exceeding 1000°F. Galvanised steel hoses, while durable, typically have lower heat tolerance and may degrade faster under prolonged high-heat conditions.

Q: Is a stainless steel flexible exhaust hose suitable for outdoor industrial use?

A: Absolutely. Stainless steel flexible exhaust hoses excel in outdoor or corrosive environments due to their rust-resistant properties. Their robust construction ensures longevity even when exposed to moisture, chemicals, or temperature fluctuations.

Q: How do I maintain a galvanised steel flexible exhaust hose?

A: Regularly inspect for scratches or worn zinc coatings, as exposed areas can rust. Clean with mild soap and water, avoiding abrasive tools. For severe corrosion, consider replacing with stainless steel braided hoses for enhanced protection.

Q: Why choose a stainless steel braided exhaust hose over a standard flexible model?

A: The braided design adds extra reinforcement against abrasion and pressure surges. Combined with stainless steel’s innate strength, it provides superior leak resistance and longevity, especially in high-vibration or heavy-duty exhaust systems.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.