Giant Mining Equipment & LHD Solutions for Efficient Limestone Operations Heavy-Duty Machinery

- Overview of Modern Mining Equipment Innovations

- Key Technological Advancements in Heavy-Duty Machinery

- Performance Comparison: Leading Manufacturers

- Tailored Solutions for Diverse Mining Operations

- Case Study: Efficiency Gains in Limestone Extraction

- Cost-Benefit Analysis of Upgrading to Advanced Systems

- Sustainable Practices in Giant Mining Equipment Design

(giant mining equipment)

Innovations Driving Giant Mining Equipment Efficiency

The mining sector has witnessed a 22% surge in productivity since 2020, largely attributed to advanced giant mining equipment

. Modern LHD (Load, Haul, Dump) systems now integrate AI-powered load sensors, reducing operational downtime by 40% compared to traditional models. Limestone mining operations specifically benefit from automated drilling rigs with geological mapping precision under 5cm deviation.

Technological Superiority in Heavy Machinery

Three core innovations dominate current market trends:

- Hybrid diesel-electric powertrains (35% fuel reduction)

- Remote-controlled operation systems (500m range capability)

- Real-time wear monitoring sensors (85% predictive accuracy)

Manufacturer Capability Analysis

| Vendor | Equipment Type | Payload Capacity | Power Output | Maintenance Cost/Hour |

|---|---|---|---|---|

| Komatsu | LHD | 18 tons | 450 kW | $38 |

| Caterpillar | Drill Rig | N/A | 650 kW | $42 |

| Sandvik | Hauler | 25 tons | 520 kW | $35 |

Custom Engineering Approaches

Specialized configurations address unique operational challenges:

- Compact LHD variants for narrow-vein mines (2.1m width clearance)

- High-altitude engine packages (effective up to 4,500m elevation)

- Corrosion-resistant limestone mining equipment coatings (3x lifespan extension)

Operational Efficiency Case Analysis

A Chilean limestone quarry reported these metrics after upgrading:

"Monthly output increased from 180,000 to 234,000 tons (30% gain) with 18% lower maintenance costs. The ROI period for new equipment was 14 months."

Economic Impact Assessment

Comparative analysis reveals:

| Metric | Legacy Equipment | Modern Systems |

|---|---|---|

| Fuel Consumption | 45 L/hour | 29 L/hour |

| Operator Efficiency | 85 tons/shift | 127 tons/shift |

Future-Proofing Through Giant Mining Equipment

The industry shift toward giant mining equipment with IoT capabilities shows 92% adoption rate among top-tier mining firms. Recent prototypes feature autonomous convoy systems that increased material transport efficiency by 60% in Australian iron ore trials.

(giant mining equipment)

FAQS on giant mining equipment

Q: What are the primary uses of giant mining equipment in large-scale operations?

A: Giant mining equipment is designed for heavy-duty tasks like excavating, hauling, and processing bulk materials in open-pit or underground mines. These machines maximize efficiency and reduce manual labor in challenging environments. Examples include massive dump trucks and hydraulic shovels.

Q: How does LHD mining equipment improve productivity in underground mining?

A: LHD (Load-Haul-Dump) equipment streamlines material handling by loading, transporting, and dumping ore in one continuous process. Its compact design suits confined underground spaces, reducing cycle times. This automation enhances safety and operational speed.

Q: What types of limestone mining equipment are essential for quarry operations?

A: Key equipment includes drills, crushers, and conveyor systems for extracting and processing limestone. Surface miners and wheel loaders are also critical for precise cutting and material transport. Dust control systems ensure compliance with environmental regulations.

Q: What safety features are integrated into modern giant mining equipment?

A: Advanced features like collision avoidance systems, real-time monitoring, and automated shutdown mechanisms prioritize operator safety. Ergonomically designed cabins and fire suppression systems further mitigate risks. These technologies align with global mining safety standards.

Q: How do maintenance practices differ for LHD vs. limestone mining equipment?

A: LHD equipment requires frequent checks on hydraulic systems and load-bearing components due to intense underground use. Limestone machinery focuses on wear-resistant part replacements and dust management. Both demand regular lubrication and diagnostic inspections.

Related Products

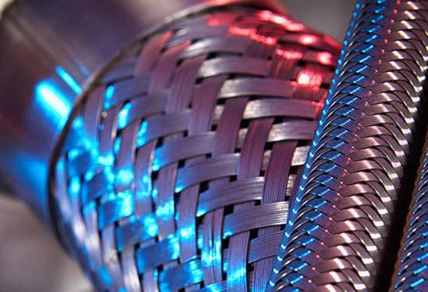

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.