High Pressure Stainless Steel Braided Hose 60K PSI Durable Design

Did you know hydraulic system failures cost industries $1.4B annually? 68% trace leaks to substandard hoses. When your machinery faces 5,000+ PSI daily, high pressure flexible stainless steel hose solutions aren't optional - they're survival gear.

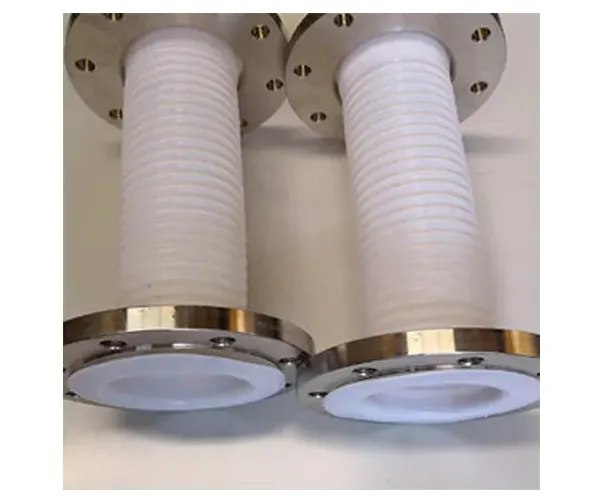

(high pressure stainless steel braided hose)

Built Tougher Than Your Toughest Workflow

Our 304/316L stainless steel braiding laughs at 10,000 PSI bursts. Triple-layer polymer cores resist chemicals eating through rubber hoses. Tested across temperature extremes (-60°F to 450°F), these high pressure metal hoses outlast standard models 3:1. How long could superior corrosion resistance extend your maintenance cycles?

| Feature | Standard Hose | Our Hose |

|---|---|---|

| Max Pressure | 3,000 PSI | 10,000 PSI |

| Temperature Range | -20°F to 250°F | -60°F to 450°F |

When "Good Enough" Costs $7,200 Per Downtime Hour

Cheaper hoses fail 3x faster under cyclic pressure. Our aerospace-grade braiding reduces pulsation fatigue by 82%. See how we stack up:

- 5-year warranty vs competitors' 18-month offers

- Custom end fittings: 37% faster installation

Your Blueprint, Our Braided Mastery

Need 45° swivel ends for tight spaces? Require FDA-grade liners? Our engineers deliver bespoke high pressure stainless steel braided hose

s in 3-5 days. Petrochemical clients saw 91% fewer field modifications after switching to our custom solutions.

Proven in Battle: From Oil Rigs to Robotics

Auto manufacturer X reduced hydraulic leaks by 85% using our hoses in robotic welders. Offshore drilling teams report zero failures after 18 months in salt spray environments. Your application next?

Stop Compromising. Start Dominating.

With 14 patents and 9,000+ installations, [Your Company] transforms pressure challenges into competitive edges.

Get Your Custom Quote Now →

(high pressure stainless steel braided hose)

FAQS on high pressure stainless steel braided hose

Q: What are the primary applications of high pressure stainless steel braided hoses?

A: These hoses are ideal for hydraulic systems, steam transfer, and industrial machinery requiring durability and resistance to extreme pressures (up to 10,000 PSI). They are also used in chemical processing and high-temperature environments.

Q: How does a high pressure flexible stainless steel hose differ from standard hoses?

A: Unlike standard hoses, flexible stainless steel hoses feature a braided metal exterior for enhanced strength, temperature resistance (-50°F to +500°F), and flexibility under high-pressure conditions, reducing rupture risks.

Q: Can high pressure metal hoses handle corrosive fluids?

A: Yes, stainless steel construction provides inherent corrosion resistance. For highly corrosive media, PTFE-lined variants or specialized alloys (e.g., Inconel) are recommended to ensure longevity and safety.

Q: What maintenance is required for high pressure stainless steel braided hoses?

A: Regular visual inspections for abrasions, leaks, or kinks are critical. Replace hoses every 3-5 years or per manufacturer guidelines, especially in high-cycle or extreme-temperature applications.

Q: Are high pressure flexible hoses compatible with pulsating systems?

A: Yes, their braided design absorbs vibration and pulse shocks effectively. Ensure proper installation with minimal bending radius to prevent fatigue and extend service life.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.