Efficient Lead Extraction from Ore Advanced Lead Ore Processing & Flotation

Unlock Higher Yields: The Revolution in Lead Extraction from Ore

Are you struggling to boost output from your lead ore processing line? You’re not alone. Industry reports show that over 60% of production plants still lose up to 15% of extractable lead due to outdated methods. A 2023 survey found that only 42% of global facilities achieve efficiency rates above 80%. That’s millions lost every year. Let’s break the cycle. It’s time for a smarter, cleaner, more profitable future.

(lead extraction from ore)

Cutting-Edge Technologies in Lead Extraction from Ore

Technology changes fast. Modern lead extraction from ore

has moved beyond simple smelting. Advanced gravity separation, eco-friendly chemical reagents, and automated flotation systems now boost yields and cut environmental risks. Staged lead-zinc flotation maximizes recovery—even from complex polymetallic ores. Latest digital ore analyzers cut analytical time by 35%, leading to real-time decision making. Bottom line? You get higher yields. Consistently. The numbers prove it.

| Process | Lead Recovery Rate (%) | Power Use (kWh/ton) |

|---|---|---|

| Old-School Smelting | 72 | 265 |

| Modern Flotation | 89 | 158 |

How Top Vendors Stack Up in Lead Ore Processing

Not all solutions are the same. The best lead ore processing partners offer:

- Patented reagent formulas (8-21% yield gain vs. generic reagents)

- PLC-driven flotation flowsheets for peak efficiency

- On-site training and expert support teams

- Proven pilot runs

Side-by-side, leaders use automation and process intelligence. That means less downtime. Less error. More output. You stay ahead. Why settle for average when you can beat the global benchmark?

| Vendor | Lead-Zinc Yield (%) | Service Response | Compliance |

|---|---|---|---|

| Generic Supplier | 79 | 72 hrs | Basic |

| Innovative Solutions Inc. | 91 | 24 hrs | ISO+Eco |

Custom Lead-Zinc Flotation Solutions for Your Plant

No two ore bodies are alike. That’s a fact. We bring advanced lead-zinc flotation expertise right to your door. Our engineers tailor every solution—reagent mix, agitation, cell sizing—to your unique feed. Need more automation? Easy. Want AI-based online grade monitoring? We’ve done it. Customers see payback in under eighteen months. You get higher grade concentrates. Fewer tails. Smaller carbon footprint.

See How Our Lead Extraction Expertise Drives Results

Real stories. Real performance. In 2023, a Romanian mine saw 21% higher concentrate grade in 60 days using our solution—while energy use dropped 28%. An African smelter doubled capacity after upgrading to our PLC flotation lines. Downtime? Slashed by over 60%. Hundreds worldwide trust us to deliver better ore yields, less waste, and a cleaner process.

Ready to transform your lead ore processing? Imagine unlocking extra revenue from the same tons—while meeting all environmental rules. That’s the power of advanced lead extraction from ore.

Contact [YourCompany]: Let’s upgrade your plant. Free consultation. Proven results. Higher profit starts today—act now and be a leader in lead extraction!

(lead extraction from ore)

FAQS on lead extraction from ore

Q: What is lead extraction from ore?

A: Lead extraction from ore is the process of obtaining pure lead metal from its natural mineral sources. The process involves several physical and chemical steps. It is crucial for producing lead for industrial uses.Q: How is lead ore processed before extraction?

A: Lead ore processing involves crushing, grinding, and concentrating the ore to separate metal-bearing minerals. This may include flotation and other separation techniques. Processing ensures higher efficiency during the extraction of lead.Q: What is lead zinc flotation?

A: Lead zinc flotation is a method used to separate lead and zinc minerals from their ore. It utilizes chemicals and air bubbles to selectively attach and remove desired metal particles. This step is essential in the beneficiation of complex ores containing both metals.Q: Why is flotation important in lead ore processing?

A: Flotation is important because it increases the concentration of lead in the ore, improving yield and purity. It separates valuable minerals from the unwanted gangue materials. This step is vital for efficient lead extraction from lower-grade ores.Q: What are the main challenges in lead extraction from ore?

A: The main challenges include ore complexity, presence of impurities, and environmental concerns. Efficient separation and purification are required to overcome these issues. Modern techniques aim to enhance recovery while minimizing environmental impact.Related Products

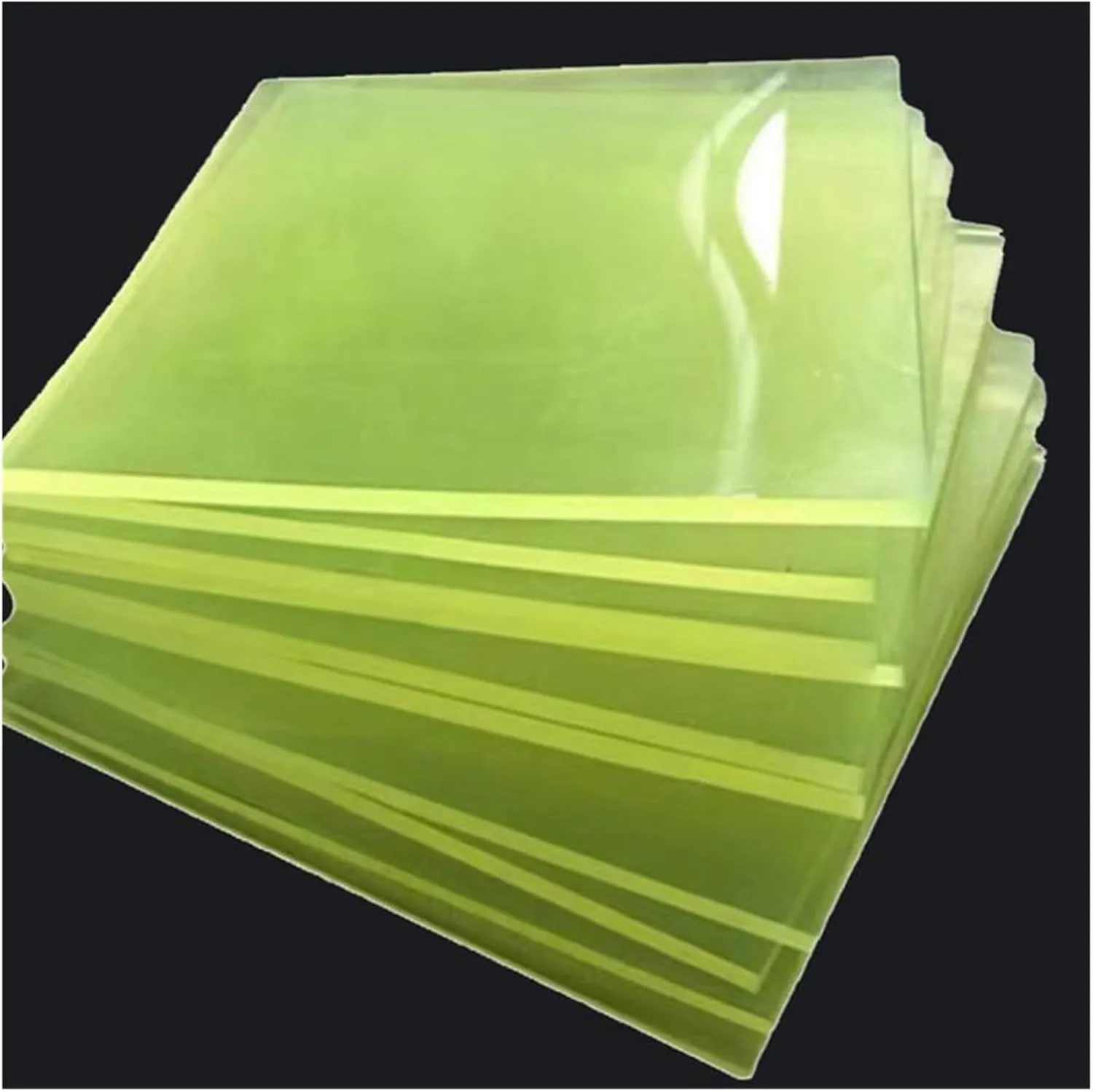

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.