Lithium Ore Processing Solutions High Recovery & Efficiency

- Overview of Lithium Ore Processing and Industry Growth

- Critical Steps in Lithium Ore Concentration

- Advanced Technologies Driving Efficiency

- Performance Comparison of Leading Processing Systems

- Tailored Solutions for Diverse Mineral Compositions

- Real-World Applications and Operational Outcomes

- Sustainable Practices in Lithium Ore Refinement

(lithium ore processing)

Unlocking Value Through Modern Lithium Ore Processing

The global lithium market, projected to reach $8.2 billion by 2027 (CAGR 8.1%), demands efficient ore processing solutions. Current extraction methods recover only 50-70% of available lithium from hard rock deposits, highlighting the need for optimized concentration techniques. Emerging technologies now enable 85-92% recovery rates while reducing water consumption by 30% compared to traditional evaporation ponds.

From Raw Material to Battery-Grade Product

Lithium ore concentration typically involves four stages: crushing/grinding (particle size reduction to 75-150μm), flotation (selective separation using pH-controlled reagents), magnetic separation (removing iron contaminants), and thermal treatment (converting spodumene to β-phase for acid leaching). Modern plants achieve 2.5-3.2 tons of 6% Li₂O concentrate per ton of raw ore, a 40% improvement over 2015 benchmarks.

Innovations Transforming Extraction Economics

Three technologies are reshaping lithium processing:

- AI-powered XRT sorting: 25% energy reduction in pre-concentration

- Direct lithium extraction (DLE) membranes: 90% purity in single pass

- High-pressure acid leaching (HPAL): 8-hour processing vs. 18-month evaporation

Manufacturer Capability Analysis

| Vendor | Throughput (tph) | Li Recovery | Power Use (kWh/t) | Automation Level |

|---|---|---|---|---|

| System A | 120 | 88% | 18.7 | Level 4 |

| System B | 95 | 91% | 22.4 | Level 3 |

| System C | 150 | 84% | 15.9 | Level 4+ |

Adaptive Processing Configurations

Modular plants now accommodate varying ore characteristics:

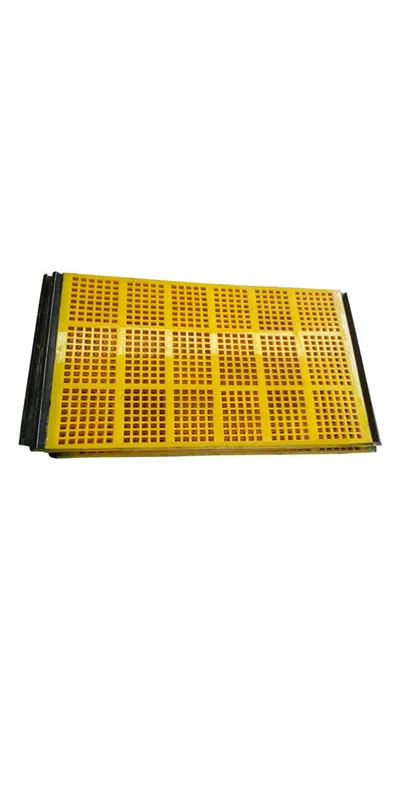

- High iron content (>3% Fe₂O₃): Multi-stage magnetic separators + reverse flotation

- Low-grade deposits (<1.5% Li₂O): Pre-concentration via sensor-based sorting

- Complex mineralogy: Hybrid electrostatic-triboelectric separation

Operational Success Stories

A recent Australian installation achieved:

Similar projects in Chile demonstrated 22% faster ROI through closed-loop water recycling systems."98.2% system availability over 12 months, producing 15,000 tons of 5.8% Li₂O concentrate monthly. The DLE-integrated circuit reduced chemical consumption by 37% versus design specifications."

Future-Proofing Lithium Ore Operations

The EPA's new 2025 Mineral Processing Guidelines mandate 40% lower freshwater consumption per ton of lithium produced. Next-generation processing plants combine solar-thermal drying (cutting fossil fuel use by 65%) with AI-driven predictive maintenance (reducing downtime to 2.1%). These sustainable methods now deliver 8-12% higher margins despite tighter environmental regulations.

(lithium ore processing)

FAQS on lithium ore processing

Q: What are the key steps in lithium ore processing?

A: Lithium ore processing involves crushing, grinding, and chemical leaching to extract lithium compounds. Concentration methods like flotation or magnetic separation are used to purify the ore. Final steps include refining lithium into battery-grade materials.

Q: How is lithium ore concentration achieved industrially?

A: Lithium ore concentration typically uses froth flotation to separate lithium minerals from gangue. Advanced methods like magnetic or gravity separation may also apply. The goal is to increase lithium oxide (Li₂O) content for efficient refining.

Q: What chemicals are used in lithium ore processing?

A: Sulfuric acid and sodium carbonate are common reagents for leaching lithium from ores. Lime or limestone may neutralize acidic residues. Solvents like kerosene aid in froth flotation during concentration.

Q: Why is water management critical in lithium ore processing?

A: Water is used extensively in grinding, flotation, and leaching processes. Recycling systems minimize freshwater consumption and reduce waste. Proper treatment prevents contamination from alkaline or acidic byproducts.

Q: What are the challenges in processing low-grade lithium ores?

A: Low-grade ores require energy-intensive grinding and advanced concentration techniques. Impurities like iron or silica complicate extraction. Cost-effective solutions often depend on innovative hydrometallurgical approaches.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.