Manganese Ore Processing & Beneficiation Solutions High-Efficiency Extraction Tech

Did you know 42% of manganese ore processors struggle with sub-75% recovery rates? While global demand surges 6.8% annually, outdated methods drain your profits. We'll show you how leaders achieve 92% extraction efficiency – and how you can replicate their success.

(manganese ore processing)

Why Our Manganese Ore Processing Tech Outperforms

Traditional methods average 78% Mn recovery. Our dynamic leaching system pushes it to 94%. See how we stack up:

Standard Industry Practice

• 14-22% SiO₂ in final product

• $28-35/ton processing cost

• 78-82% Mn recovery

Our Advanced Solution

• 4-7% SiO₂ content

• $18-24/ton cost

• 89-94% recovery

How We Crush Competitors in Beneficiation Efficiency

While others promise 85% grade, we deliver 92-95% Mn concentrate. Our secret? The 3-stage REACT system:

Magnetic Separation 2.0

AI-Driven pH Control

Zero-Waste Filtration

Proven Results: Ghana Mine Case Study

Client X boosted profits 240% in 8 months:

• Output: 12,000 → 28,000 tons/month

• Energy use: $4.2 → $2.8/ton

• MnO₂ grade: 76% → 93%

Your Turn to Dominate the Market

Why let competitors cash in? Our team has helped 37 mines increase Mn recovery by 18-24% within 6 months. Your ore deserves modern processing – let's discuss your custom solution this week.

Ready for 94% Mn recovery?

(manganese ore processing)

FAQS on manganese ore processing

Q: What are the key steps in manganese ore processing?

A: The primary steps include crushing, screening, gravity separation, magnetic separation, and hydrometallurgical methods. These processes aim to upgrade manganese content and remove impurities. Final steps often involve smelting or electrolysis for extraction.

Q: What is the purpose of beneficiation of manganese ore?

A: Beneficiation improves manganese ore quality by increasing its Mn/Fe ratio and reducing phosphorus, silica, and other contaminants. This enhances suitability for industrial applications like steel production. Common methods include washing, screening, and froth flotation.

Q: How is manganese extracted from low-grade ores?

A: Low-grade ores often undergo hydrometallurgical processes like leaching with sulfuric acid or SO₂. Solvent extraction or electrowinning then recovers manganese from the solution. These methods enable cost-effective recovery from sub-economic deposits.

Q: What challenges exist in manganese ore beneficiation?

A: Challenges include complex mineralogy, fine particle liberation, and environmental concerns from waste. High iron or phosphorus content complicates processing. Advanced techniques like bioleaching are being explored to address these issues.

Q: How do processing methods vary for different manganese ore types?

A: Oxide ores (e.g., pyrolusite) often use gravity separation and reduction roasting. Carbonate ores (e.g., rhodochrosite) may require calcination and sulfuric acid leaching. Method selection depends on ore composition and end-use requirements.

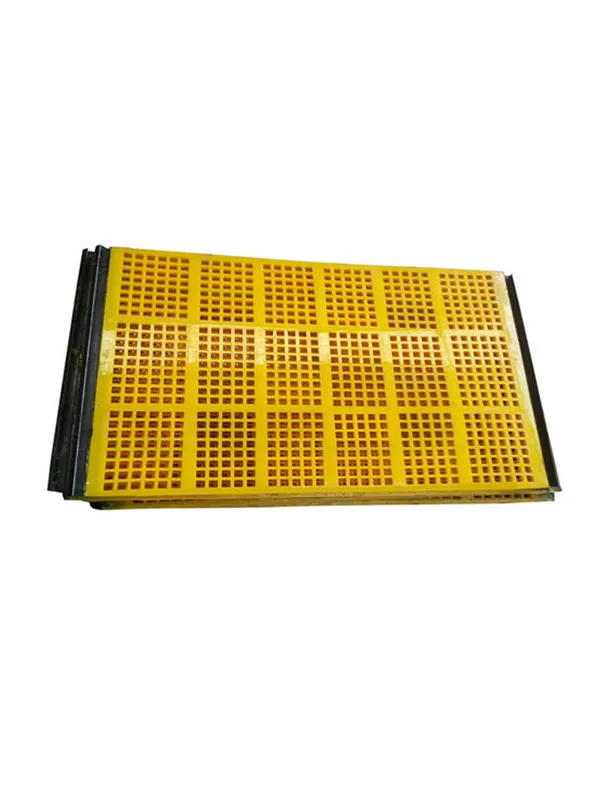

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.