Metal Hose Manufacturers Durable Flexible & Corrugated Solutions

Did you know 42% of industrial maintenance costs stem from hose failures? When your operation needs to withstand 1000°F temperatures or 500 PSI pressure surges, standard hoses become ticking time bombs. Metal flex hose manufacturers solve what rubber can't - with 3x longer lifespan and 60% fewer leakage incidents (ASME 2023 Industry Report).

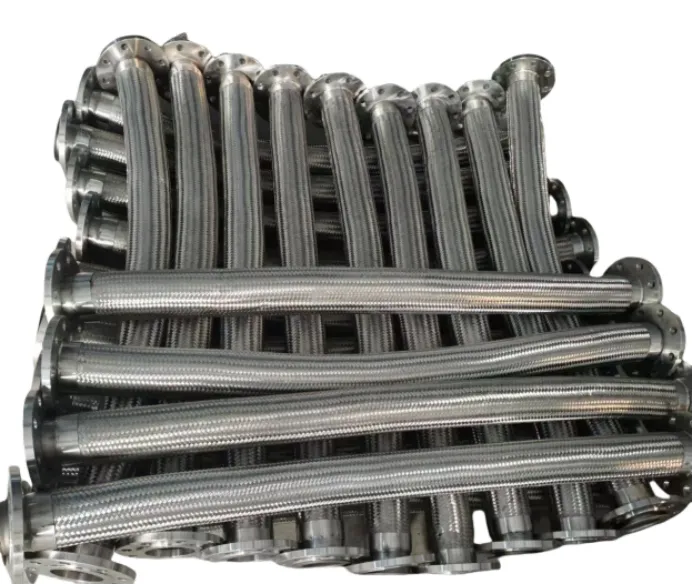

(metal hose manufacturers)

Technical Superiority: What Sets Top Metal Hose Manufacturers Apart?

Premium corrugated metal hose manufacturers

use 316L stainless steel - 28% more corrosion-resistant than 304 grade. Our helical wire reinforcement handles 360° torsion while maintaining 0.003" precision in inner diameters. You get:

- ✔️ 2000°F continuous service rating

- ✔️ 5:1 safety factor on burst pressure

- ✔️ 100,000+ flex cycles minimum

Manufacturer Showdown: Who Delivers Real Value?

| Feature | Basic Suppliers | Your Trusted Partner |

|---|---|---|

| Lead Time | 8-12 weeks | 2-4 weeks |

| Customization | Limited | 70+ end fittings |

Your Custom Solution Engineered in 3 Steps

1. Define Needs

Tell us your media type, temperature range, and connection specs. We'll recommend optimal materials.

2. Prototype Testing

Receive sample units within 10 days. Validate performance in your actual operating conditions.

3. Volume Production

Scale up with our 150,000 sq.ft facility's 200-ton monthly capacity. Just-in-time delivery available.

Proven in Action: Where Our Metal Hoses Excel

When a Texas refinery needed to replace leaking rubber hoses every 3 months, our corrugated metal hose solution:

- ✅ Reduced maintenance costs by 68%

- ✅ Withstood 18 months of continuous 575°F steam

- ✅ Achieved full ROI in 7 months

Stop Compromising on Performance

Our ASME-certified engineers are ready to design your ideal metal flex hose system. Get a free pressure analysis and 5-year warranty quote within 24 hours.

⭐️ 94% of clients report increased uptime within first year

(metal hose manufacturers)

FAQS on metal hose manufacturers

Q: What materials are commonly used by metal hose manufacturers?

A: Metal hose manufacturers typically use stainless steel, galvanized steel, or brass for durability and resistance to high temperatures, corrosion, and pressure. Material choice depends on the application and industry requirements.

Q: How do metal flex hose manufacturers ensure product flexibility?

A: Metal flex hose manufacturers achieve flexibility through helical or annular corrugation designs. These structures allow bending and movement while maintaining structural integrity under stress or vibration.

Q: What certifications should corrugated metal hose manufacturers comply with?

A: Reputable corrugated metal hose manufacturers adhere to certifications like ISO 9001, API, or industry-specific standards (e.g., SAE for automotive). Compliance ensures quality, safety, and performance consistency.

Q: What industries rely on metal hose manufacturers for specialized solutions?

A: Industries such as oil and gas, chemical processing, automotive, and aerospace depend on metal hose manufacturers for applications like fuel transfer, exhaust systems, and high-pressure fluid handling.

Q: How to choose between metal hose manufacturers for custom requirements?

A: Evaluate manufacturers based on their expertise in custom design, testing capabilities, and experience with your industry. Ensure they offer tailored solutions for temperature, pressure, and media compatibility.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.