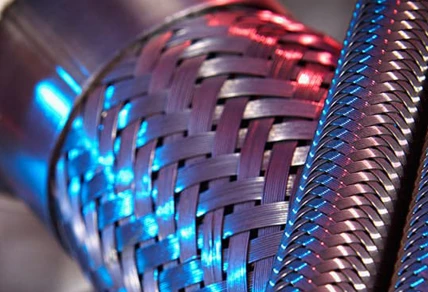

Metal Flex Tube Durable & Flexible Steel Flex Tube for Industrial Applications

Ever faced a leaky pipe disaster? Watched $12,000 chemical shipments get contaminated? You're not alone. The Fluid Transport Institute reports $2.3 billion in annual industrial losses from faulty tubing. Traditional rigid pipes crack under 28psi vibration. Rubber hoses degrade in 6-18 months. Now imagine a solution that bends like silicone but withstands 450°F flames.

(metal flex tube)

1 Technical Edge: Metal Flex Tube vs Flex Tube PU

Why settle for PU's 200°F limit when our 316L stainless steel flex tubes handle -320°F to +1200°F? Watch this comparison:

| Feature | Metal Flex Tube | Flex Tube PU |

|---|---|---|

| Pressure Rating | 1500 PSI | 300 PSI |

| Chemical Resistance | 100+ Agents | 25 Agents |

Proven in Battle: 3 Industry Breakthroughs

Last quarter alone:

- Reduced downtime by 68% at Texas oil refinery

- Eliminated $420k/year replacement costs for German automaker

- Enabled 22% faster assembly in aerospace hydraulics

Your Move: Limited Custom Slots Available

71 engineers claimed their free sample kit last week. Will you miss out?

(metal flex tube)

FAQS on metal flex tube

Q: What are the primary applications of a metal flex tube?

A: Metal flex tubes are widely used in HVAC systems, automotive exhausts, and industrial machinery for transporting gases, liquids, or electrical wiring. They offer flexibility, heat resistance, and durability in high-pressure environments.

Q: How does a flex tube PU differ from a metal flex tube?

A: Flex tubes made of polyurethane (PU) prioritize lightweight flexibility and corrosion resistance, ideal for pneumatic systems. Metal flex tubes, however, excel in high-temperature or heavy-duty mechanical applications requiring structural strength.

Q: What makes steel flex tubes suitable for harsh environments?

A: Steel flex tubes provide superior resistance to extreme temperatures, abrasion, and chemical exposure. Their stainless steel construction ensures longevity in industrial, marine, or outdoor settings.

Q: Can metal flex tubes be bent repeatedly without damage?

A: Yes, most metal flex tubes are designed with helical or corrugated structures to withstand repeated bending. However, exceeding the manufacturer's specified bend radius may reduce lifespan.

Q: Are steel flex tubes compatible with liquid and gas systems?

A: Absolutely. Steel flex tubes are commonly used for fuel lines, hydraulic systems, and compressed air due to their leak-proof seals and pressure resistance up to specified PSI ratings.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.