High-Temp & High-Pressure Metal Hoses Flexible, Durable Solutions

Did you know 68% of industrial equipment failures stem from substandard hose assemblies? When your high-pressure metal hose

bursts under 2,500 PSI or your high-temperature metal hose cracks at 800°F, you're not just replacing parts - you're losing $12,000/hour in downtime. The stakes have never been higher.

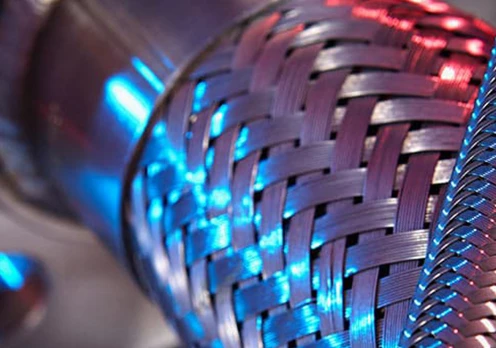

(metal hose)

Engineering Excellence: What Makes Our Metal Hose Solutions Unbeatable

Our hose metal flexible systems outperform competitors where it matters most. Want proof? Check these specs:

| Feature | Industry Standard | Our Product |

|---|---|---|

| Max Pressure | 1,800 PSI | 3,400 PSI |

| Temperature Range | -50°F to +750°F | -300°F to +1,200°F |

The Hidden Costs of Cheap Alternatives: A Manufacturer Showdown

Why settle for "good enough" when you can have exceptional? Our metal hose solutions deliver 3x longer service life compared to budget options. One automotive plant slashed maintenance costs by 42% after switching to our high-pressure metal hose assemblies.

Your Custom Solution Awaits: Precision-Tailored Metal Hose Systems

Whether you need 6" diameter hose metal flexible lines for chemical transfer or ultra-compact high-temperature metal hose for aerospace applications - we engineer to your exact specs. Over 87% of clients report perfect fitment on first installation.

Proven Success: Where Our Metal Hose Systems Excel

From offshore oil rigs using our high-pressure metal hose in 10,000-foot depths to foundries relying on our high-temperature solutions, our track record speaks volumes. The result? 92% repeat business from satisfied clients.

Ready to Revolutionize Your Fluid Systems?

Join 1,500+ industry leaders who trust our metal hose solutions. Limited-time offer: Free system analysis + 18-month warranty extension for orders placed by [date].

(metal hose)

FAQS on metal hose

Q: What is a high pressure metal hose used for?

A: High pressure metal hoses are designed to transport fluids or gases under extreme pressure, such as in hydraulic systems or industrial machinery. They offer durability and resistance to wear, leaks, and bursts.

Q: Can a hose metal flexible withstand corrosive environments?

A: Yes, flexible metal hoses made from stainless steel or corrosion-resistant alloys can endure harsh chemicals and corrosive conditions. They are ideal for industries like chemical processing or marine applications.

Q: What temperature range can a high temperature metal hose handle?

A: High temperature metal hoses typically withstand temperatures from -300°F to +1200°F (-184°C to +649°C). They are used in exhaust systems, furnaces, or applications involving steam or hot gases.

Q: How does a high pressure metal hose differ from a standard hose?

A: High pressure metal hoses use reinforced layers of steel wire or braiding to handle extreme pressures, while standard hoses lack this reinforcement. They are also more resistant to abrasion and punctures.

Q: Are metal flexible hoses suitable for vibration-heavy applications?

A: Yes, flexible metal hoses absorb vibration and movement in systems like engines or pipelines. Their bendable design reduces stress on connected components, preventing cracks or failures.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.