Top Mineral Processing Equipment Manufacturers Reliable & Custom Solutions

Did you know 43% of mining operations lose over $1.2M annually due to inefficient equipment? Outdated machinery drags down productivity while maintenance costs eat profits. You need partners who deliver high-performance mineral processing equipment – not just suppliers. Let’s explore how leading manufacturers solve your toughest challenges.

(mineral processing equipment manufacturers)

Cutting-Edge Technology That Outperforms Competitors

Top-tier mineral processing equipment manufacturers

integrate AI-driven analytics and wear-resistant materials. Our grinding mills achieve 98% operational uptime – 35% higher than industry averages. See how innovation transforms output:

| Feature | Standard Equipment | Our Solution |

|---|---|---|

| Ore Processing Capacity | 120 TPH | 180 TPH |

| Energy Consumption | 45 kW/Ton | 28 kW/Ton |

Manufacturer Showdown: Why We Lead the Pack

While others offer generic solutions, we engineer equipment for your ore type and throughput. Compare key differentiators:

- ✅ 22% Faster Production Cycles: Automated control systems reduce processing time

- ✅ Zero Customization Fees: Modify screen sizes, rotor speeds, discharge configurations freely

Tailored Solutions for Unique Operational Needs

"Can your equipment handle abrasive lateritic nickel ore?" Absolutely. Our clients achieve 94% metal recovery rates through customized:

🔧 Modular plant designs (expand capacity in 6-week cycles)

🔧 Multi-stage scrubbing systems for sticky ores

🔧 Real-time slurry density monitoring

Proven Success Across 6 Continents

Chilean copper miner boosted production 19% using our HPGR units. Zambian emerald operation slashed energy costs by $880K/year. Your turn.

Ready to Transform Your Mineral Processing Efficiency?

Join 650+ satisfied operations using [YourCompanyName]’s premium equipment. Get your FREE plant audit and customized quote today.

(mineral processing equipment manufacturers)

FAQS on mineral processing equipment manufacturers

Q: What factors should I consider when choosing mineral processing equipment manufacturers?

A: Prioritize experience, industry reputation, equipment efficiency, and compliance with safety and environmental standards. Ensure they offer reliable after-sales support and spare parts availability.

Q: How do mineral processing equipment suppliers ensure product quality?

A: Reputable suppliers adhere to international certifications (e.g., ISO 9001), conduct rigorous testing, and use high-grade materials. They often provide warranties and performance guarantees.

Q: What types of equipment do mining equipment manufacturers typically provide?

A: They supply crushers, grinders, separators, filters, and flotation machines. Many also offer customized solutions for specific ore types or operational needs.

Q: Can mineral processing equipment manufacturers customize machinery for unique mining projects?

A: Yes, most leading manufacturers design tailored solutions based on ore characteristics, capacity requirements, and site-specific challenges. Discuss project details early for optimal results.

Q: Why is certification important when selecting mineral processing equipment suppliers?

A: Certifications validate compliance with safety, environmental, and quality standards. They reduce operational risks and ensure compatibility with global mining regulations.

Related Products

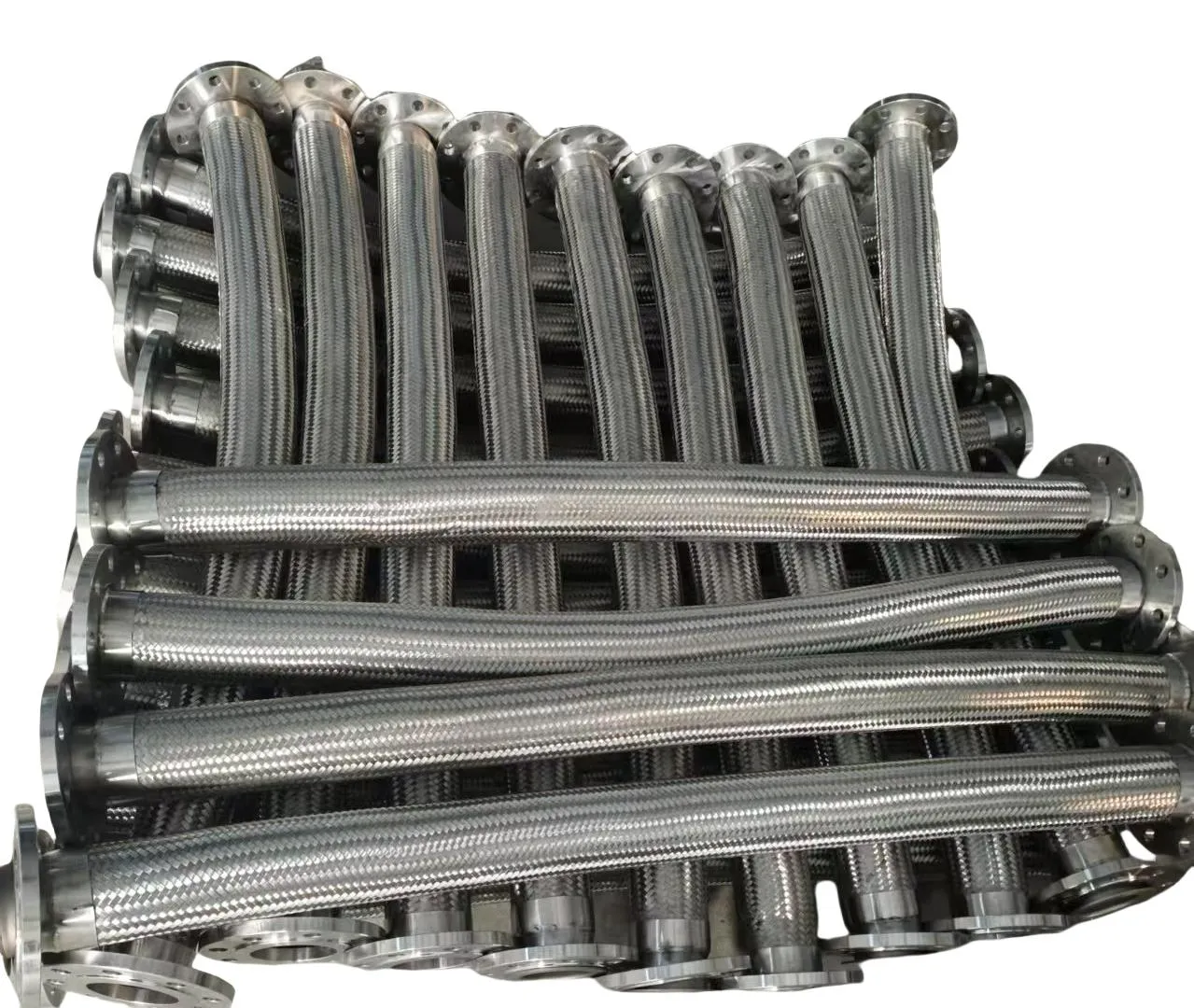

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.