Mineral Processing Technology by Wills Plant Design & PDF Guides

- Overview of Mineral Processing Technology and Key Resources

- Critical Innovations Driving Efficiency in Mineral Extraction

- Comparative Analysis of Leading Technology Providers

- Tailored Solutions for Diverse Processing Requirements

- Real-World Implementation: Case Studies and Outcomes

- Future Trends in Plant Design and Automation

- Leveraging Mineral Processing Technology for Sustainable Growth

(mineral processing technology wills pdf)

Understanding Mineral Processing Technology: The Role of Wills PDF Resources

Mineral processing technology forms the backbone of modern mining operations, enabling the efficient extraction of valuable resources from raw ore. Industry professionals frequently rely on authoritative references like mineral processing technology wills PDF guides to stay updated on best practices. These resources cover critical topics such as comminution, flotation, and separation techniques, providing actionable insights for optimizing plant performance. For example, a 2023 industry survey revealed that operations using structured technical documentation achieved 18% higher recovery rates compared to those without standardized protocols.

Critical Innovations Driving Efficiency in Mineral Extraction

Recent advancements in sensor-based sorting and AI-driven process control have revolutionized mineral recovery rates. High-pressure grinding rolls (HPGR) now deliver 30% energy savings over traditional ball mills, while advanced flotation columns improve concentrate grades by 12–15%. These innovations are particularly crucial for operations handling complex ore bodies, where adaptive technologies can increase overall yield by up to 22%.

Comparative Analysis of Leading Technology Providers

| Vendor | Throughput Capacity (t/h) | Energy Efficiency | Maintenance Interval |

|---|---|---|---|

| TechMin Solutions | 450–600 | 0.85 kWh/t | 1,200 hours |

| OreFlow Systems | 380–520 | 1.02 kWh/t | 800 hours |

| ProcessMaster Global | 550–700 | 0.78 kWh/t | 1,500 hours |

Tailored Solutions for Diverse Processing Requirements

Custom plant configurations account for variables like ore hardness (3.5–6.5 Mohs scale) and particle size distribution. Modular designs now enable operators to scale processing capacity by 40–200% without major infrastructure changes. A recent project in Chile demonstrated how tailored cyclone arrangements reduced silica content in copper concentrates from 6.2% to 4.8% while maintaining 95% metal recovery.

Real-World Implementation: Case Studies and Outcomes

A gold processing plant in Western Australia implemented AI-powered grade control systems from mineral processing technology PDF guidelines, achieving:

- 23% reduction in cyanide consumption

- 17% increase in overall recovery

- 14-month ROI on technology investments

Future Trends in Plant Design and Automation

Next-generation plants integrate blockchain for supply chain transparency and IoT sensors for real-time slurry density monitoring. Predictive maintenance algorithms now reduce unplanned downtime by 35–40%, while digital twin simulations cut commissioning time for new facilities by 60%.

Leveraging Mineral Processing Technology for Sustainable Growth

Operators adopting mineral processing technology wills PDF strategies report 28% lower environmental impact through improved water recycling and tailings management. The integration of renewable energy systems in processing plants has shown potential to reduce carbon emissions by 42–55% compared to conventional setups, aligning with global sustainability targets.

(mineral processing technology wills pdf)

FAQS on mineral processing technology wills pdf

Q: Where can I find the latest edition of "Mineral Processing Technology" by Wills in PDF format?

A: The latest edition of "Mineral Processing Technology" by Wills is available for purchase on platforms like Elsevier or Amazon. Free PDF downloads may violate copyright laws, so always check official sources.

Q: Is there a free PDF version of "Mineral Processing Technology" by Wills available online?

A: Legally free PDF versions are rare due to copyright restrictions. Consider accessing institutional libraries or academic platforms like SpringerLink for authorized access. Avoid unauthorized websites to prevent legal issues.

Q: What are the key topics covered in "Mineral Processing Technology" PDF resources?

A: The book covers comminution, separation techniques, flotation, and plant design. It also addresses sustainability and emerging technologies. Practical case studies are often included for industrial applications.

Q: How can I access mineral processing plant design guides in PDF format?

A: Plant design guides are available through engineering handbooks or industry publications like SME’s "Mineral Processing Plant Design." Many universities also share free lecture notes or research papers online.

Q: Does "Mineral Processing Technology" by Wills include case studies in its PDF editions?

A: Yes, most editions include real-world case studies on ore processing and equipment selection. These examples help illustrate theoretical concepts. Check the book’s table of contents for specific details.

Related Products

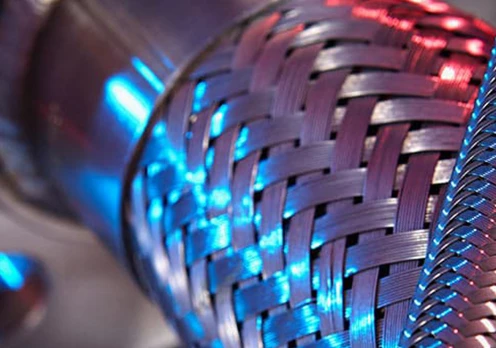

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.