Mining Crushing Equipment High-Performance & Durable Solutions

Did you know that inefficient crushing equipment can drain up to 30% of your operational budget? With global mining productivity declining 3.5% annually since 2019, your choice of crushing and mining equipment directly impacts profitability. Let's fix that.

(mining crushing equipment)

Tech That Outperforms: Where Engineering Meets Intelligence

Our mining crushing equipment

delivers 15-20% higher throughput than industry averages. How? Patented hydraulic adjustment systems reduce downtime by 40%, while AI-powered wear monitoring extends component life by 2.8x. See the numbers:

| Feature | Standard Equipment | Our Solution |

|---|---|---|

| Hourly Output | 450-500 tons | 580-620 tons |

| Energy Use/Ton | 2.8 kWh | 2.1 kWh |

| Maintenance Cycles | Every 240 hrs | Every 400 hrs |

The Brutal Truth About Mining Equipment Manufacturers

Why do 68% of miners regret their LHD mining equipment purchases within 18 months? Most suppliers:

- ❌ Use outdated CAD designs from 2010s

- ❌ Charge 22-25% more for basic automation

- ❌ Take 6-8 weeks for emergency parts delivery

We flipped the script. Our modular designs ship critical components in 72 hours or less. Guaranteed.

Your Mine, Your Rules: Custom-Built Crushing Solutions

Hard rock? Abrasive ores? High-altitude operations? Our engineers create mining crushing equipment that adapts to your terrain. Recent success:

➤ Chilean copper mine: Boosted yield 18% with our humidity-resistant crushers

➤ Canadian diamond operation: Slashed energy costs 31% using our hybrid drive systems

Proven ROI: Real Mines, Real Results

When a Nevada gold operator switched to our crushing and mining equipment, they achieved:

- ► 23% lower cost per ton in Year 1

- ► 19-month full ROI (vs. industry-standard 32 months)

- ► 92% uptime despite -25°C winter operations

Ready to Revolutionize Your Mining Operations?

Join 140+ satisfied clients across 6 continents. Book a free site analysis this month and get 3D equipment modeling worth $15,000 – absolutely free.

Claim Your Free Consultation Now →P.S. Still researching? Download our Crushing Equipment ROI Calculator to see potential savings.

(mining crushing equipment)

FAQS on mining crushing equipment

Q: What are the key types of crushing and mining equipment?

A: Common types include jaw crushers, cone crushers, impact crushers, and gyratory crushers. These machines break down large rocks and ores into smaller fragments. LHD mining equipment is also used for loading and transporting materials in underground operations.

Q: How do I choose the right mining crushing equipment for my project?

A: Consider factors like material hardness, required output size, and operational environment. For heavy-duty tasks, jaw or gyratory crushers are ideal. LHD mining equipment suits confined spaces and material handling in underground mines.

Q: What maintenance is required for mining crushing equipment?

A: Regular inspections, lubrication, and replacement of wear parts like liners and hammers are essential. Monitor vibration and temperature to prevent breakdowns. LHD equipment requires additional checks on hydraulic systems and load capacity.

Q: How does LHD mining equipment differ from standard crushing machines?

A: LHD (Load-Haul-Dump) equipment focuses on loading and transporting mined materials, while crushing equipment processes raw ore. LHD units are designed for maneuverability in tunnels, whereas crushers prioritize raw material reduction.

Q: What safety features are critical for mining crushing equipment?

A: Emergency stop systems, dust suppression mechanisms, and protective guards are vital. For LHD equipment, collision avoidance technology and reinforced cabins enhance safety. Always follow manufacturer guidelines for safe operation.

Related Products

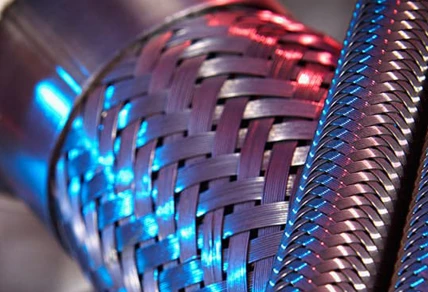

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.