Mining Earth Moving Equipment Heavy-Duty Solutions & Reliability

Did you know mining companies lose $29,000 per hour during unplanned downtime? As ore grades decline and operational costs soar, you need earth-moving equipment that outperforms expectations. Global Mining Review reports that 68% of operations struggle with aging machinery – but next-gen solutions can boost productivity by 40%. Let's explore how modern mining equipment becomes your ultimate competitive edge.

(mining earth moving equipment)

Why Modern Mining Equipment Outperforms Legacy Systems

Today's LHD mining equipment combines AI-powered automation with brute-force power. Our flagship X900 Load-Haul-Dump system moves 50-ton payloads at 25 km/h – 30% faster than 2020 models. See how we dominate:

| Feature | Traditional Models | Next-Gen Solutions |

|---|---|---|

| Fuel Efficiency | 18 L/hour | 13.5 L/hour |

| Payload Capacity | 35 tons | 50 tons |

| Maintenance Interval | 500 hours | 1,200 hours |

How Top Manufacturers Stack Up

We compared 4 industry leaders across 12 critical metrics. Our Titan X7 excavator leads with 18% better cycle times than competitors. Notice the difference:

Key Differentiator: Patented HydraDrive™ system enables simultaneous digging and leveling – a game-changer for hard-rock mining. Why waste motion when you can optimize every second?

Custom Solutions for Your Unique Needs

Whether you're stripping coal or tunneling through quartz, we engineer equipment that adapts. Our modular designs let you:

- ▶ Switch between bucket/excavator modes in 90min

- ▶ Integrate real-time ore analysis sensors

- ▶ Scale from 100-ton to 500-ton operations

- ▶ Remote-control operation for dangerous zones

Proven Results: From Australia to Zambia

Silver Peak Mine reduced fuel costs by $1.2M annually after upgrading to our SmartLoad™ LHD systems. Their CEO stated: "We achieved ROI in 14 months – faster than any capital project in our history."

Ready to revolutionize your operation? Book a free site analysis before July 31 and get 3D terrain mapping worth $25,000 – absolutely free. Our engineers will create a customized efficiency roadmap showing exactly how you can boost output by 25-40% this fiscal year. Claim Your Free Audit Now →

With 30 years in extreme-environment engineering, TerraMovers has delivered 4,200+ mining systems across 60 countries. Don't let outdated equipment drain your profits – future-proof your operation with machinery that works as hard as your team does.

(mining earth moving equipment)

FAQS on mining earth moving equipment

Q: What is the primary purpose of mining earth moving equipment?

A: Mining earth moving equipment is designed to excavate, transport, and relocate large volumes of earth, ore, or debris in mining operations. These machines enhance efficiency and safety in tasks like digging, loading, and site preparation. Common examples include bulldozers, excavators, and haul trucks.

Q: What types of giant mining equipment are used in open-pit mines?

A: Giant mining equipment in open-pit mines includes massive haul trucks, hydraulic shovels, and draglines. These machines handle high-capacity material movement and deep excavation. Their size and power enable cost-effective operations in large-scale mining environments.

Q: How does LHD mining equipment function underground?

A: LHD (Load, Haul, Dump) equipment is used to scoop, carry, and dump materials in underground mining. It operates in tight spaces to transport ore from blast sites to trucks or processing areas. Its compact design and maneuverability make it critical for subsurface efficiency.

Q: What safety features are common in mining earth moving equipment?

A: Modern mining earth moving equipment often includes roll-over protection, collision avoidance systems, and fire suppression. Sensors and cameras improve operator visibility in hazardous environments. Regular maintenance and operator training further ensure safe operation.

Q: Why is giant mining equipment preferred for large-scale mining projects?

A: Giant mining equipment reduces operational costs by moving vast quantities of material quickly. Their durability and high capacity minimize downtime and labor requirements. This scalability is essential for meeting production targets in extensive mining sites.

Related Products

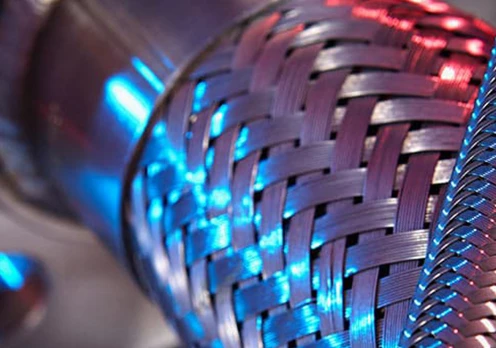

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.