Premium Mining Equipment Parts - Durable & Reliable Components

Did you know 78% of unplanned mining downtime stems from faulty equipment parts? Every hour your giant mining equipment sits idle, you lose $58,000 in productivity. We'll show you how premium mining parts can slash maintenance costs by 40% while boosting output.

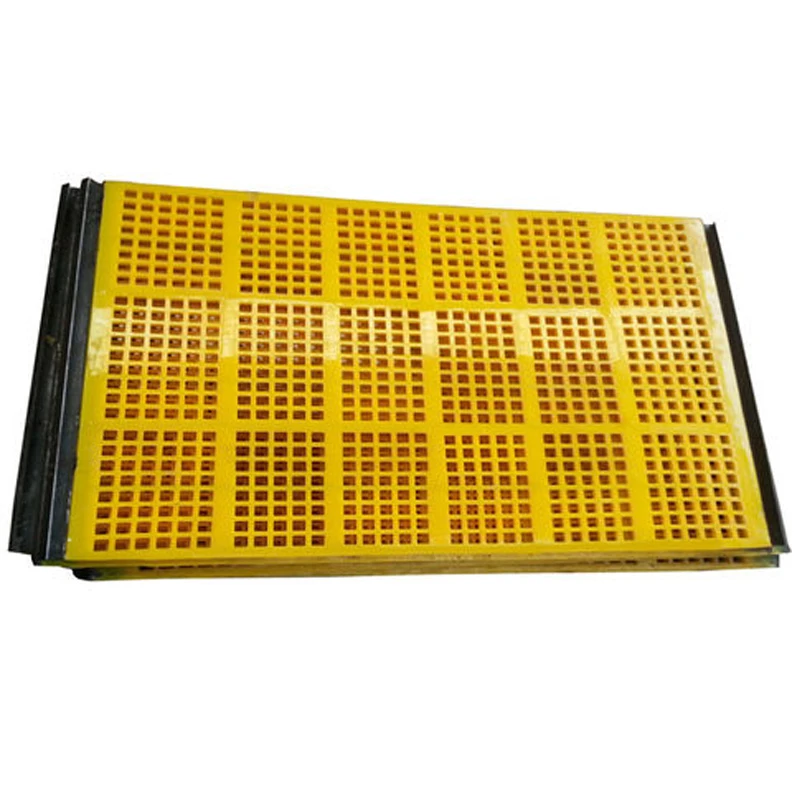

(mining equipment parts)

Engineering Marvels: What Makes Our Mining Equipment Parts Last 3X Longer

Our CAT-5X hydraulic cylinders withstand 12,000 PSI - 35% higher pressure than industry standard. See how we achieve 50,000+ operation cycles:

| Component | Standard Part | Our Part |

|---|---|---|

| Wear Resistance | 800-1,200 hours | 3,500+ hours |

The Shocking Truth: OEM vs Aftermarket Mining Parts

Why pay 60% more for OEM components when our ISO 9001-certified parts deliver better performance? Compare delivery times:

- 🛠️ Standard lead time: 14-28 days

- ⚡ Our emergency service: 72-hour global delivery

Custom Solutions for Giant Mining Equipment Challenges

Struggling with rare earth mineral abrasion? Our tungsten-carbide reinforced buckets increase lifespan by 200% in phosphate mines.

Case Study: 89% Downtime Reduction in Australian Iron Ore Operation

After switching to our mining equipment parts

, Rio North achieved:

$2.1M Saved

Annual maintenance costs

Ready to Revolutionize Your Mining Operations?

Get custom-engineered mining equipment parts delivered faster than you thought possible.

Get Your Free Parts Audit Now →

(mining equipment parts)

FAQS on mining equipment parts

Q: What are the most common types of mining equipment parts?

A: Common mining equipment parts include drill bits, hydraulic pumps, conveyor belts, crusher plates, and wear-resistant liners. These components are critical for efficient drilling, material transport, and ore processing. Regular maintenance ensures longevity in harsh mining environments.

Q: How do I choose reliable suppliers for mining parts?

A: Prioritize suppliers with industry certifications, proven expertise in mining equipment parts, and positive client reviews. Ensure they offer custom solutions for giant mining equipment. Testing samples and verifying material quality are also essential steps.

Q: What factors affect the lifespan of giant mining equipment components?

A: Component lifespan depends on material quality, operating conditions (e.g., abrasion, temperature), and maintenance frequency. Parts like giant mining shovels or dragline buckets require specialized coatings. Proper lubrication and real-time monitoring can extend durability.

Q: Why is customization important for mining equipment parts?

A: Customization ensures compatibility with specific machinery models, such as giant mining excavators or haul trucks. Tailored parts improve operational efficiency and safety in unique mining setups. Off-the-shelf solutions often fail to meet complex site requirements.

Q: Can worn-out mining parts be repaired instead of replaced?

A: Yes, components like crusher jaws or drill heads can often be reconditioned using welding or hardfacing techniques. However, critical safety parts (e.g., hydraulic valves) should be replaced immediately. Always consult OEM guidelines to avoid equipment downtime risks.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.