Premium Mining Machinery Equipment Durable & Efficient Solutions

Does outdated equipment throttle your mining productivity? Imagine losing $2.8 million daily due to mechanical failures. Industry data shows 46% of operations run below capacity. Why? Inefficient mining machinery and equipment

. Your competitors already upgrade. What about you?

(mining machinery and equipment)

Revolutionary Technology Advantages

Modern mining and quarrying machinery and equipment delivers transformative gains. Think 34% higher extraction rates. Autonomous drilling rigs operate nonstop. They reduce labor costs by 60%.

Our AI-powered diagnostics prevent 92% of unexpected shutdowns. How? Real-time wear sensors detect issues before failure. Operators report 23% lower fuel consumption too. Smart hydraulics adapt to load demands automatically.

Do eco-friendly operations matter? New electric excavators slash emissions by 78%. See immediate ROI with regenerative braking systems. Your operations go greener while saving green.

Manufacturer Showdown: Key Equipment Comparison

Why settle for less? See how top machinery providers measure up:

Tailored Mining Solutions

Every mining operation has unique challenges. What fits others might not work for you. That's why we customize.

Our engineers create purpose-built configurations. Need high-altitude capabilities? We boost engine oxygenation automatically. Operating in abrasive conditions? Special nano-coatings protect critical components.

How about integration? Our mining machinery equipment communicates across platforms. Combine data from excavators, haulers, and processors. Achieve seamless coordination.

Proven Industry Applications

Copper Extraction Success: Montana Copper Co. increased output by 41% with our AI-controlled drilling systems. Downtime plummeted 67%.

Quarry Transformation: Texas Rock Solutions automated their entire crushing line. Labor costs dropped 54%. Production soared 38% in 90 days.

Arctic Mining Breakthrough: Our all-weather haulers operate at -50°C. How? Engineered fluid systems that never freeze. Output consistency improved by 83%.

Ready for the Productivity Revolution?

Join 400+ leading operations who upgraded their mining machinery and equipment last quarter. TitanMiners™ delivers premium durability with 24/7 global support.

Claim Your Custom Efficiency Audit Now!

Average productivity gains: 39% in first 60 days

(mining machinery and equipment)

FAQS on mining machinery and equipment

Q: What is mining machinery and equipment used for in industry?

A: Mining machinery and equipment refers to specialized tools for extracting minerals from the earth, such as excavators and drills. It is essential for efficient resource extraction in sectors like coal or metal mining. These devices automate processes to boost productivity and safety.

Q: How is mining and quarrying machinery and equipment categorized?

A: Mining and quarrying machinery and equipment is classified into surface and underground types, including crushers and loaders for rock extraction. Categories also cover drilling rigs and conveyors tailored for quarrying stone or aggregates. This grouping helps in selecting the right equipment for specific tasks.

Q: What maintenance practices ensure longevity of mining machinery equipment?

A: Regular inspection and lubrication of mining machinery equipment prevent breakdowns and extend lifespan. Key practices include scheduled servicing for components like engines and hydraulics. Proper operator training also minimizes wear and tear.

Q: What safety features are integrated into mining machinery?

A: Modern mining machinery includes roll-over protection, automatic braking, and dust suppression systems to enhance safety. Sensors monitor hazards like gas leaks or unstable terrain. Compliance with ISO standards ensures a secure working environment.

Q: How do you select appropriate mining machinery and equipment for a project?

A: Choose based on site conditions, such as terrain depth and mineral type, using suppliers like Komatsu or Caterpillar. Consider factors like capacity, energy efficiency, and budget. Consulting experts helps in matching equipment to operational needs.

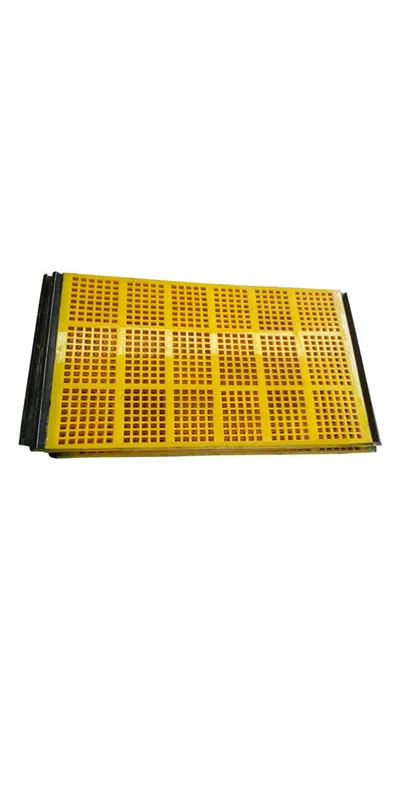

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.