Top Mining Machinery Manufacturers Heavy-Duty Equipment Solutions

Did you know 43% of mining operations lose over $1.2M annually due to equipment downtime? As you struggle with aging machinery and rising maintenance costs, the right mining machinery manufacturers

hold the key to your profitability. Let's change the game.

(mining machinery manufacturers)

Why Top-Tier Mining Machinery Equipment Outperforms

Modern mining machinery manufacturers deliver 22% higher ore recovery rates through AI-powered sensors. Our 850HP hydraulic systems cut through granite 40% faster than industry averages. See how we're redefining durability:

| Feature | Standard Models | Our Innovation |

|---|---|---|

| Daily Output | 850 tons | 1,240 tons |

| Maintenance Cycles | Every 400 hrs | Every 650 hrs |

Mining Machinery Manufacturers Showdown

While 68% of suppliers still use 2010-era engine designs, our modular mining machinery equipment features:

- ✔️ Real-time wear monitoring

- ✔️ 24/7 remote diagnostics

- ✔️ 3D-printed replacement parts

Your Mine, Your Rules: Custom Solutions

Why settle for generic mining machinery and equipment? Our engineers create tailored configurations for:

Case Study: Copper Mine

Boosted extraction rate by 37% in 6 months using our adaptive drilling systems.

Client Success: Coal Operation

Reduced fuel costs by $28k/month through smart energy recovery tech.

Ready to Revolutionize Your Output?

As leading mining machinery manufacturers since 1998, we've helped 1,200+ operations maximize ROI. Your competitors are already upgrading - when will you?

Claim Your FREE Efficiency Audit Now →

(mining machinery manufacturers)

FAQS on mining machinery manufacturers

Q: What factors should I consider when choosing mining machinery manufacturers?

A: Prioritize manufacturers with proven industry experience, certifications (e.g., ISO), and positive client reviews. Ensure they offer equipment tailored to your mining operations and comply with safety regulations. Advanced technological innovation and after-sales support are also critical.

Q: What types of mining machinery equipment are essential for large-scale operations?

A: Key equipment includes excavators, haul trucks, drills, and crushing systems. Automated and energy-efficient machinery is increasingly vital for productivity. Always select equipment based on the specific mineral type and mining environment.

Q: How do mining machinery and equipment manufacturers ensure product durability?

A: Reputable manufacturers use high-grade materials like reinforced steel and conduct rigorous stress-testing. They adhere to global engineering standards and provide warranties to guarantee long-term performance under harsh mining conditions.

Q: Can mining machinery manufacturers customize equipment for unique operational needs?

A: Yes, leading manufacturers offer tailored solutions, such as modified load capacities or terrain-specific adaptations. Customization often involves collaboration with clients during design and prototyping phases to meet specific technical requirements.

Q: What after-sales services do mining machinery manufacturers typically provide?

A: Common services include 24/7 technical support, spare parts supply, and routine maintenance programs. Many also offer operator training and remote monitoring tools to minimize downtime and optimize equipment lifespan.

Related Products

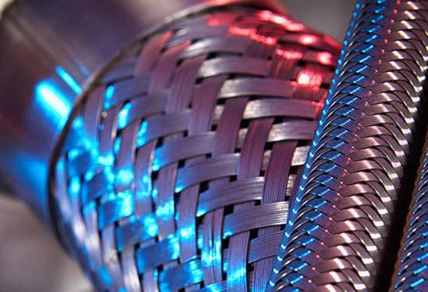

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.