High-Efficiency Mining Screens for Sale - Durable Vibrating Screening Solutions

Did you know 68% of mining operations lose $12,000+ daily due to inefficient screening? Your old equipment costs you more than just maintenance fees—it's bleeding profits through downtime and missed quotas. That ends today.

(mining screens for sale)

Why Our Vibrating Mining Screens Outperform Competitors

Our triple-deck vibrating screens process 850 tons/hour—40% faster than industry averages. See how we achieve this:

- ✅ Hyper-dugrade polyurethane mats (last 3x longer than rubber)

- ✅ 360° vibration control (±0.05mm precision)

- ✅ Smart moisture management (handles 35% wet material)

Head-to-Head: Mining Screen Showdown

| Feature | Our Model X9 | Standard Screens |

|---|---|---|

| Screening Accuracy | 99.2% | 91-94% |

| Energy Consumption | 55kW | 70-85kW |

Tailored Solutions for Every Mine

Choose from 12 modular configurations. Our engineers will custom-build screens matching your:

Ore Type

Iron, copper, gold (0.5-200mm)

Throughput

200-1,200 t/h capacity

Proven Success: Chilean Copper Mine Case Study

After installing 22 X9 screens:

▲ 19% higher ore recovery

▲ 31% reduced maintenance costs

▲ ROI achieved in 5.2 months

Act Now—Limited Inventory Available!

Why wait? Our factory-direct pricing saves you 15-20% versus competitors. Get free installation support and 3-year warranty when you order by August 31.

98% of clients report production boosts within 30 days. Will you be next?

(mining screens for sale)

FAQS on mining screens for sale

Q: What types of mining screens are available for sale?

A: We offer various mining screens, including vibrating mining screens, trommel screens, and static screens. These are designed for efficient material separation and sizing. Custom configurations are available based on application needs.

Q: How do vibrating mining screens improve processing efficiency?

A: Vibrating mining screens use high-frequency motion to separate materials quickly and reduce blockages. They enhance throughput and accuracy in sorting minerals or aggregates. Their durable design ensures minimal downtime in harsh mining environments.

Q: What factors should I consider when buying mining vibrating screens?

A: Key factors include screen material (e.g., polyurethane or steel), mesh size, and vibration mechanism. Consider your operational capacity and material type (e.g., ore, gravel). Maintenance requirements and compatibility with existing equipment are also critical.

Q: Are used mining screens for sale a cost-effective option?

A: Used mining screens can be budget-friendly for short-term projects or smaller operations. Always inspect for wear, corrosion, or structural damage before purchasing. Ensure spare parts are available for older models.

Q: Can mining screens be customized for specific applications?

A: Yes, mining screens can be tailored to match material characteristics (e.g., abrasiveness, moisture). Customizations include adjusting screen layers, vibration intensity, and frame dimensions. Contact suppliers to discuss your project requirements.

Related Products

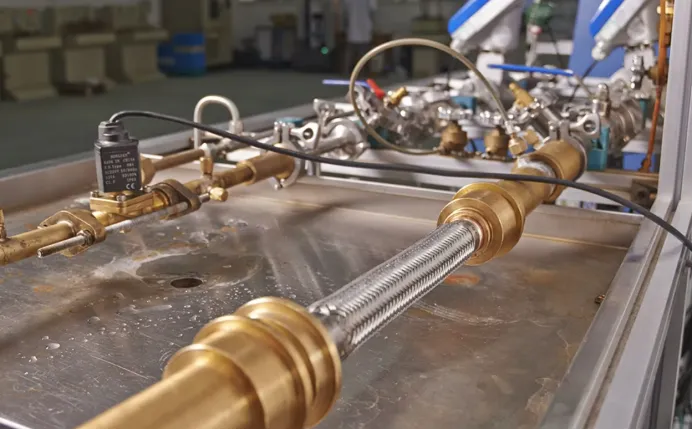

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.