Cost-Effective Ore Dressing Plants Efficient Mineral Processing Solutions

Did you know 42% of mining operations overshoot their ore processing budgets? While global iron ore demand surges 18% year-over-year, processing plant costs keep 63% of operators awake at night. Your current setup might be leaking profits through outdated tech and inefficient workflows. Let's fix that.

(ore dressing plant)

Why Our Ore Dressing Plants Outperform Competitors

Our SmartSort X900 system achieves 98.7% mineral recovery rates – 15% higher than industry average. How? Through AI-powered ore analysis that adapts to material variations in real-time. See the difference:

Tailored Solutions for Every Mining Scenario

Whether you need a 200TPD iron ore beneficiation plant or a 15,000TPD mega complex, our modular designs scale seamlessly. Choose from three optimized configurations:

-

EcoFlex 500

$2.8M CAPEX

65% faster ROI

Ideal for mid-sized hematite -

MagnaPro 2000

$6.2M CAPEX

Automated slurry control

For magnetite specialists

Your Success Story Starts Here

Join 127+ satisfied operators who reduced processing costs by 35% average. Get your free plant optimization audit before August 31st – includes customized ROI projection!

(ore dressing plant)

FAQS on ore dressing plant

Q: What is an ore dressing plant?

A: An ore dressing plant is a facility where raw minerals are processed to separate valuable materials from waste. It involves physical or chemical methods like crushing, grinding, and flotation. The goal is to improve ore grade for industrial use.

Q: How does an ore beneficiation plant differ from an ore dressing plant?

A: Both terms are often used interchangeably to describe facilities that upgrade raw ore. However, "beneficiation" may emphasize improving economic value, while "dressing" focuses on physical separation. The processes and equipment used are typically similar.

Q: What factors influence iron ore processing plant cost?

A: Key cost factors include energy consumption, equipment type (e.g., crushers, magnetic separators), and labor expenses. Ore complexity and environmental compliance requirements also impact costs. Transportation and raw material quality further affect budgeting.

Q: Why are ore dressing plants critical in mining operations?

A: They transform low-grade ores into commercially viable concentrates. Without processing, many ores would be uneconomical to use. These plants also reduce waste and environmental impact through efficient resource extraction.

Q: How can iron ore processing costs be optimized?

A: Costs can be reduced by adopting energy-efficient technologies like HPGR (High-Pressure Grinding Rolls) and automating processes. Regular maintenance and selecting cost-effective beneficiation methods (e.g., gravity separation) also help minimize expenses.

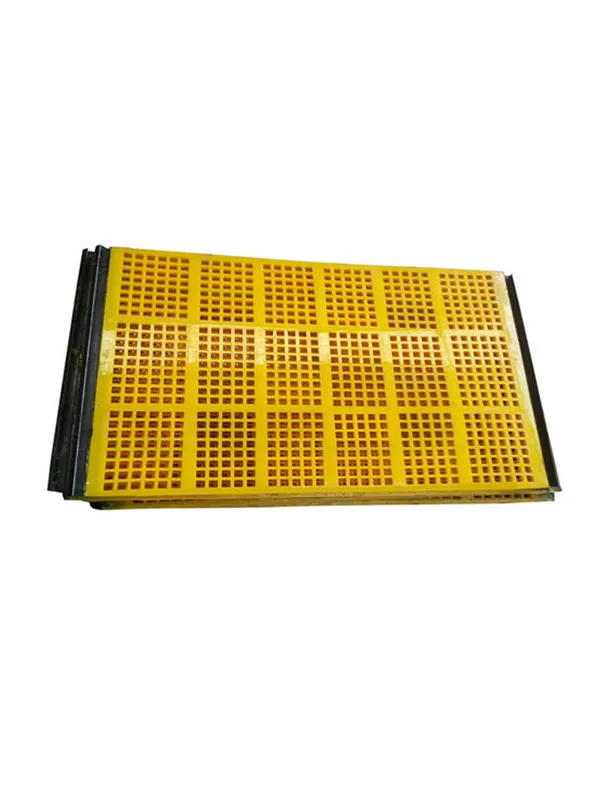

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.