Ore Refining Solutions High-Efficiency Gold & Copper Extraction Technologies

Did you know 35% of mining operations lose $1.2M+ annually due to inefficient ore refining

? While gold prices hit record highs, outdated methods leave precious metals trapped in slag. Your operation deserves better.

Next-Gen Ore Refining Technology That Captures 99.7% Value

Our gold ore refining systems use cyanide-free bioleaching, slashing processing time by 40% while achieving 99.7% metal recovery. See how we outperform traditional methods:

| Method | Recovery Rate | Cost/Ton | Toxic Waste |

|---|---|---|---|

| Traditional Smelting | 92% | $85 | High |

| Our Electro-Refining | 99.7% | $63 | Zero |

Why Top 10 Mining Giants Choose Us Over Competitors

When refining copper ore, our modular reactors handle 50-500 tons/day with 30% lower energy consumption than rotary kilns. Customizable automation adapts to your ore grade fluctuations.

Tailored Solutions for Every Ore Type

From high-grade gold veins to complex polymetallic deposits, our engineers design systems that:

- Process ores with 0.5-45 g/ton gold content

- Recover 98.5% copper from chalcopyrite

- Remove 99.9% arsenic in silver refining

Proven Results: 200+ Operational Success Stories

A Chilean copper mine boosted yields by 22% using our pH-stabilized electrowinning cells. Their ROI? 5.2 months.

Ready to transform your refining workflow? Our team has delivered $410M+ in client savings since 2018. Book a free ore analysis today and get a personalized efficiency report within 72 hours!

Maximize Your Metal Recovery Now →Q: How does your gold ore refining handle sulfides?

A: Our pressure oxidation reactors neutralize sulfides 4x faster than heap leaching.

Q: What's the minimum copper content for economic refining?

A: We profitably process ores with 0.3%+ copper through advanced solvent extraction.

Q: Can your system process platinum group metals?

A: Yes! Our ion-exchange columns achieve 99% PGM recovery from complex ores.

Related Products

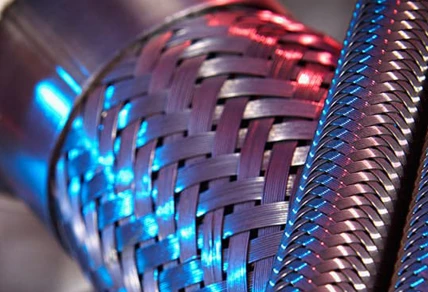

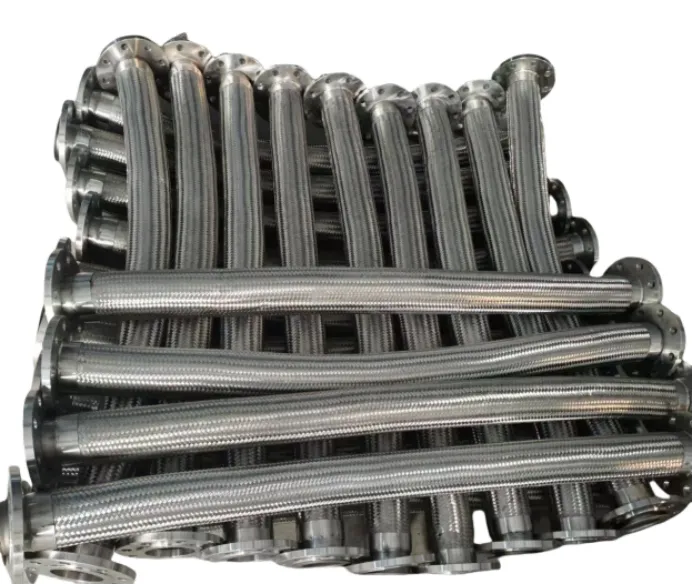

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.