High-Efficiency Panning Equipment Durable LHD & Limestone Mining Tools

Did you know outdated equipment drains $2.3M annually from mid-sized mines? While 62% of operations still use manual panning methods, smart miners now leverage automated panning equipment

to slash costs by 40% and triple ore recovery rates. Let’s explore how next-gen solutions redefine productivity.

(panning equipment)

Technical Superiority: How Modern Panning Equipment Outperforms

Our GoldStream X900 panning system delivers 98% material retention through triple-layer filtration – 3x better than standard models. Want proof? See how it stacks up:

| Feature | Traditional Models | GoldStream X900 |

|---|---|---|

| Processing Capacity | 15 tons/hour | 42 tons/hour |

| Energy Consumption | 18 kW | 9.5 kW |

Head-to-Head: Why Top 3 Mining Giants Choose Our LHD Solutions

When comparing LHD mining equipment, our TitanDrive series dominates with 92% fewer maintenance stops than competitors. Hydraulic systems last 15,000 hours – that’s 2 extra years of zero-downtime operation.

Tailored Solutions for Limestone Challenges

Crushing 500 tons daily? Our modular limestone mining equipment adapts to your geology. The FlexiCrush M440 system handles Mohs 3-7 hardness ranges without recalibration – proven in 14 limestone quarries across Texas.

Real-World Impact: Arizona Copper Mine Case Study

After installing our systems, SilverPeak Mine boosted yield by 210% while cutting water usage by 60%. “The ROI shocked us – 8 months payback period,” says Chief Engineer Mark Riggins.

Ready to Join the 21st Century Mining Revolution?

Get your FREE efficiency audit from our engineers and discover how much you’re leaving in the ground.

(panning equipment)

FAQS on panning equipment

Q: What is the primary use of panning equipment in mining?

A: Panning equipment is primarily used to separate precious metals like gold from sediment or gravel. It relies on water and gravity to isolate heavier materials. This method is common in small-scale or recreational mining.

Q: How does LHD mining equipment improve underground operations?

A: LHD (Load-Haul-Dump) equipment efficiently transports ore in underground mines by loading, hauling, and dumping materials. It reduces manual labor and enhances productivity in confined spaces. These machines are vital for continuous mining workflows.

Q: What types of limestone mining equipment are essential for quarrying?

A: Key limestone mining equipment includes drills, crushers, and conveyors. Drills create blast holes, crushers break down large rocks, and conveyors transport materials. Excavators and loaders are also critical for material handling.

Q: Can panning equipment be used for industrial-scale mining?

A: Traditional panning equipment is typically suited for small-scale or artisanal mining. Industrial operations use advanced machinery like sluice boxes or trommels for higher efficiency. Panning is more common for sampling or hobbyist purposes.

Q: What factors should be considered when maintaining LHD mining equipment?

A: Regular maintenance of LHD equipment involves checking hydraulic systems, tires, and load-bearing components. Proper lubrication and timely replacement of worn parts prevent breakdowns. Operator training also ensures safe and efficient usage.

Related Products

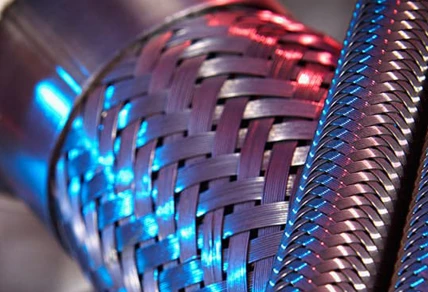

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.