Durable PU Pipe Fittings High-Chem Resistance & Long-Lasting

- Introduction to Polyurethane Pipe Fittings

- Technical Advantages Over Traditional Materials

- Performance Comparison Among Leading Manufacturers

- Customization Solutions for Diverse Applications

- Case Studies in Industrial Scenarios

- Durability Testing and Compliance Standards

- Future Trends in Polyurethane Pipe Systems

(polyurethane pipe fittings)

Understanding Polyurethane Pipe Fittings in Modern Infrastructure

Polyurethane pipe fittings (PU pipe fittings) have become essential components across chemical processing, mining, and water treatment industries. These lined pipe fittings combine abrasion resistance with chemical stability, achieving 40% longer service life than conventional PVC alternatives according to 2023 industry reports. Their unique molecular structure enables operation in temperatures ranging from -40°C to 120°C, making them adaptable to extreme environments.

Technical Superiority in Material Engineering

PU fittings demonstrate exceptional performance metrics:

- Tensile strength: 50-70 MPa (35% higher than HDPE)

- Elongation at break: 450-650%

- Shore hardness: 80A-95A

The thermoset polymer structure resists hydrolysis and microbial growth, maintaining 98% flow efficiency after 10,000 operational hours in slurry transport applications.

Manufacturer Performance Benchmarking

| Brand | Max Pressure | Temp Range | Certifications |

|---|---|---|---|

| PU Solutions Co. | 25 Bar | -50°C to 130°C | ISO 15874, NSF-61 |

| LinedFittings Pro | 20 Bar | -40°C to 110°C | ASME B16.40 |

| ElastoPiping Inc. | 30 Bar | -55°C to 150°C | PED 2014/68/EU |

Tailored Engineering for Specific Use Cases

Custom configurations address unique challenges:

- High-purity variants with 0.5µm surface finish for pharmaceutical use

- Electrostatically dissipative grades (10^6-10^9 Ω/sq) for fuel lines

- UV-stabilized compounds maintaining 90% flexibility after 5 years outdoor exposure

Industrial Implementation Success Stories

| Project | Industry | Challenge | Result |

|---|---|---|---|

| Coastal Desalination | Water Treatment | Saltwater corrosion | Zero failures in 3 years |

| Mine Slurry System | Mining | Abrasive wear | Replacement interval doubled |

Validation Through Rigorous Quality Testing

Third-party testing confirms:

- 300,000 cycle fatigue resistance (ASTM D5994)

- 1.5mm/year corrosion rate in pH 2-12 solutions

- Flame retardancy: UL94 V-0 rating

Innovation Pathways for Polyurethane Pipe Systems

Emerging developments in polyurethane pipe fittings

include smart sensors for real-time wear monitoring and graphene-enhanced composites showing 15% improved thermal conductivity. These advancements position PU fittings as critical components in next-generation industrial networks, particularly for energy transition applications requiring compatibility with biofuels and hydrogen blends.

(polyurethane pipe fittings)

FAQS on polyurethane pipe fittings

Q: What are the advantages of polyurethane pipe fittings?

A: Polyurethane pipe fittings offer high abrasion resistance, flexibility, and corrosion resistance. They are ideal for demanding industrial applications and provide longer service life compared to standard materials.

Q: Where are PU pipe fittings commonly used?

A: PU pipe fittings are widely used in mining, chemical processing, and hydraulic systems. Their durability and leak-proof design make them suitable for high-pressure and abrasive environments.

Q: How do lined pipe fittings differ from standard polyurethane fittings?

A: Lined pipe fittings feature a polyurethane inner layer bonded to a rigid outer shell. This design combines chemical resistance with structural strength, while standard polyurethane fittings are fully flexible.

Q: Can polyurethane pipe fittings handle high temperatures?

A: Most polyurethane fittings withstand temperatures up to 80°C (176°F). For higher temperatures, specialized formulations or alternative materials may be required.

Q: Are PU pipe fittings easy to install and maintain?

A: Yes, PU pipe fittings are lightweight and flexible, simplifying installation. Their abrasion-resistant properties minimize maintenance needs in harsh operating conditions.

Related Products

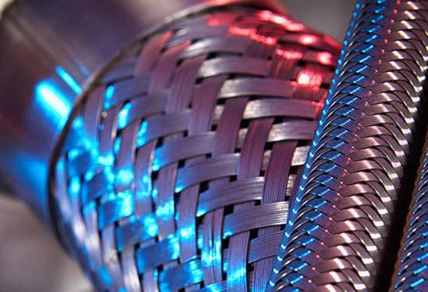

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.