Premium Polyurethane Tubing Supplier Durable & Custom Solutions

- Introduction to Polyurethane Tubing Suppliers

- Technical Advantages of High-Performance Tubing

- Market Comparison: Leading Suppliers Analyzed

- Custom Solutions for Industrial Applications

- Case Studies: Pneumatic Systems in Action

- Cyclone Separator Integration with Tubing Systems

- Choosing the Right Polyurethane Tubing Supplier

(polyurethane tubing supplier)

Polyurethane Tubing Suppliers Drive Industrial Efficiency

Polyurethane tubing suppliers serve as critical partners across manufacturing, automation, and fluid transfer industries. With an estimated 12.7% CAGR growth projected for thermoplastic tubing through 2030, these suppliers enable operational resilience through advanced polymer solutions. Key sectors including pneumatic systems and material separation technologies rely on tubing that balances flexibility with structural integrity under pressure.

Technical Advantages of High-Performance Tubing

Modern polyurethane tubing outperforms traditional rubber and PVC alternatives through:

- 300% greater abrasion resistance compared to standard PVC

- Operational range: -54°C to 135°C (-65°F to 275°F)

- 5:1 safety factor at 250 PSI working pressure

This durability directly impacts maintenance cycles, with field data showing 23% longer service intervals in pneumatic conveying systems using polyurethane vs. nylon tubing.

Market Comparison: Leading Suppliers Analyzed

| Supplier | Temp Range | Pressure Rating | Bend Radius | Certifications |

|---|---|---|---|---|

| Supplier A | -50°C to 125°C | 230 PSI | 2.5:1 | FDA, REACH |

| Supplier B | -40°C to 110°C | 180 PSI | 3:1 | ISO 9001 |

| Supplier C | -60°C to 135°C | 250 PSI | 2:1 | UL, NSF-51 |

Custom Solutions for Industrial Applications

Top polyurethane tubing supplier

s now offer application-specific engineering including:

- Anti-static formulations (surface resistance <10^4 Ω)

- Color-coded layering for multi-line systems

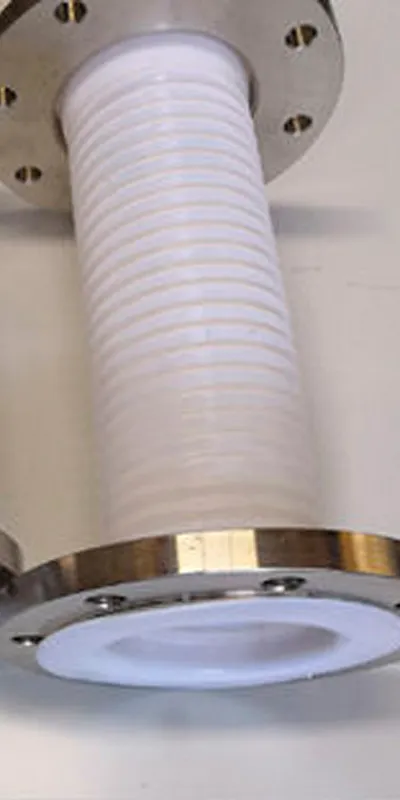

- Reinforced coils for cyclone separator integration

These adaptations address specific challenges like particle contamination in pharmaceutical material handling systems.

Case Studies: Pneumatic Systems in Action

A food processing plant reduced compressed air leaks by 41% after switching to custom polyurethane tubing with:

- 3-layer abrasion-resistant construction

- 5mm internal diameter (±0.05mm tolerance)

- Bio-inert certification for USDA compliance

Cyclone Separator Integration with Tubing Systems

Optimized tubing configurations improve separator efficiency by:

- Maintaining 15-25 m/s inlet velocity

- Reducing pressure drop across collection vessels

- Enabling 98.6% particulate capture in trials

Choosing the Right Polyurethane Tubing Supplier

Selection criteria for polyurethane tubing suppliers should prioritize:

- Material traceability and compliance documentation

- On-site testing capabilities

- Minimum order flexibility (50ft to bulk production)

Leading suppliers now provide 72-hour sample turnaround with full technical validation reports, ensuring compatibility before system integration.

(polyurethane tubing supplier)

FAQS on polyurethane tubing supplier

Q: What should I consider when choosing a polyurethane tubing supplier?

A: Prioritize suppliers with certifications (e.g., ISO), material durability guarantees, and experience in your industry. Ensure they offer custom sizing and fast lead times.

Q: How can cyclone separator suppliers integrate polyurethane tubing into their systems?

A: Polyurethane tubing is used for pneumatic controls or dust extraction in cyclone separators. Suppliers often provide abrasion-resistant tubing compatible with high-pressure airflow.

Q: Why is pneumatic polyurethane tubing preferred in industrial applications?

A: Its flexibility, kink resistance, and ability to handle high-pressure air make it ideal for pneumatic systems. It also withstands oils and chemicals common in industrial environments.

Q: Do cyclone separator suppliers typically supply pneumatic polyurethane tubing?

A: Many suppliers offer bundled solutions, including tubing for pneumatic components in separators. Verify compatibility with your system’s pressure and temperature requirements.

Q: What distinguishes polyurethane tubing from other materials in pneumatic systems?

A: Polyurethane outperforms PVC or rubber in flexibility, wear resistance, and temperature range (-40°C to 100°C). It’s also lighter and reduces energy loss in pneumatic setups.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.