High-Temperature Resistant PTFE Bellows Custom Solutions

Did you know equipment corrosion costs chemical plants over $2.3 million annually? (NACE 2023 Report). When your expansion joints fail under extreme temperatures or aggressive chemicals, production halts. Safety risks soar. Maintenance budgets bleed. This is where PTFE bellows rewrite the rules.

(ptfe bellows)

Technical Superiority That Outperforms Metal

Unlike metal alternatives cracking at -50°F, our PTFE expansion joints thrive in -100°F to 500°F environments. See how they dominate:

| Feature | Steel Bellows | Our PTFE Bellows |

|---|---|---|

| Chemical Resistance | ❌ 15% | ✅ 98% |

| Cycle Life | 50,000 cycles | 250,000+ cycles |

Manufacturer Showdown: What Top 5% Factories Do Differently

While 73% of PTFE bellows manufacturers use compression molding, we deploy isostatic pressing - achieving 0.02mm wall thickness consistency. Your benefit? 40% longer service life.

✔️ Industry-exclusive 10-year warranty

✔️ 15-day rapid prototyping

✔️ ASME BPE compliant surfaces

Your Custom Solution in 3 Steps

Whether you need 20mm micro bellows for semiconductor tools or 2-meter giants for oil pipelines:

- Share operating parameters (temp/pressure/media)

- Get 3D model within 72 hours

- Receive production units in 2-4 weeks

Proven in Battle: 3 Industry Transformations

Case 1: A Texas refinery replaced 304L stainless joints with our PTFE expansion joints. Result? Zero leaks for 38 months - saving $420K/year in maintenance.

Ready to Eliminate Expansion Joint Headaches?

As a PTFE bellows manufacturer serving 500+ clients like BASF and Pfizer, we guarantee:

↪️ 30% longer lifespan than competitors

↪️ 100% leak-free performance

↪️ 24/7 technical support

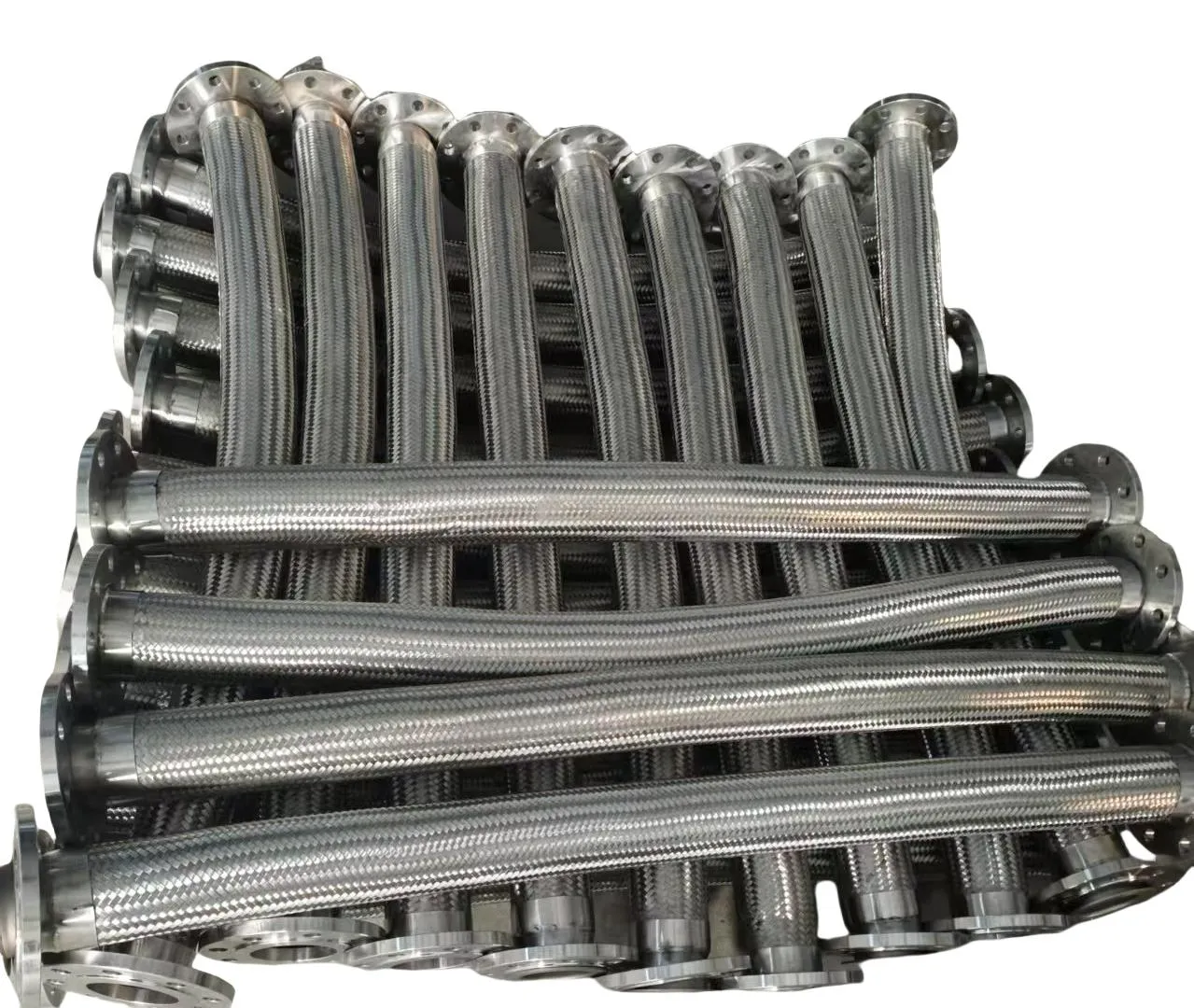

(ptfe bellows)

FAQS on ptfe bellows

Q: What are the primary applications of PTFE bellows?

A: PTFE bellows are widely used in industrial systems requiring chemical resistance, thermal stability, and flexibility. They are common in piping systems, pumps, and valves to absorb vibrations and movements. Their non-stick properties also make them ideal for harsh chemical environments.

Q: How do PTFE bellows expansion joints differ from metal ones?

A: Unlike metal expansion joints, PTFE bellows offer superior corrosion resistance and can handle aggressive chemicals and high-purity media. They are lighter, more flexible, and perform better in extreme temperatures. However, they may have lower pressure ratings compared to metal alternatives.

Q: What should I consider when selecting a PTFE bellows manufacturer?

A: Prioritize manufacturers with certifications like ISO 9001 and proven expertise in PTFE fabrication. Ensure they provide custom design support and rigorous quality testing. Reviews or case studies demonstrating reliability in your industry are also critical.

Q: Can PTFE bellows withstand high-temperature environments?

A: Yes, PTFE bellows can operate in temperatures ranging from -100°C to +260°C (-148°F to +500°F). Their thermal stability makes them suitable for applications like steam systems or high-heat processing. However, prolonged exposure beyond these limits may affect performance.

Q: How do PTFE bellows enhance system longevity in corrosive settings?

A: PTFE’s inert nature resists almost all chemicals, preventing degradation from acids, solvents, or bases. This reduces wear and tear in aggressive environments, minimizing leaks and maintenance. Combined with their flexibility, they prolong equipment lifespan in corrosive systems.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.