PTFE Bellows Manufacturer High-Temp Resistant & Custom Solutions

- Overview of PTFE bellows and core applications

- Technical specifications vs alternative materials

- Performance benchmarks across industries

- Top manufacturer capabilities comparison

- Custom design parameters and engineering support

- Installation case studies with quantitative results

- Selection criteria for expansion joint systems

(ptfe bellows)

PTFE Bellows: Engineering Solutions for Extreme Environments

Polytetrafluoroethylene (PTFE) bellows serve as critical components in chemical processing, pharmaceutical, and energy systems, with the global market projected to grow at 6.8% CAGR through 2030 (Grand View Research). Unlike standard rubber or metal expansion joints, PTFE bellows demonstrate:

- 0.02% leakage rate under 25-bar pressure cycles (ASTM F1120)

- Chemical resistance to 98% sulfuric acid at 200°C

- 500% greater flexural endurance vs fluorosilicone alternatives

Material Science Breakthroughs

Advanced PTFE composites now achieve:

| Property | Standard PTFE | Reinforced Grade | Glass-Filled |

|---|---|---|---|

| Tensile Strength | 27 MPa | 34 MPa | 42 MPa |

| Temperature Range | -70°C to 260°C | -100°C to 315°C | -200°C to 288°C |

Manufacturing Capacity Analysis

Leading PTFE bellows manufacturers differentiate through:

| Vendor | Minimum Order | Lead Time | Certifications |

|---|---|---|---|

| Supplier A | 50 units | 12 weeks | ASME, PED |

| Supplier B | 10 units | 8 weeks | ISO 9001:2015 |

Application-Specific Engineering

Custom PTFE bellows configurations address:

- Axial compression: 15mm/meter minimum

- Angular deflection: ±5° without stress concentration

- Pressure-balanced designs for vacuum service

Operational Case Evidence

Field data from chlor-alkali plant retrofit:

| Metric | Pre-Installation | Post-Installation |

|---|---|---|

| Maintenance Interval | 3 months | 22 months |

| Seal Failure Rate | 34% | 1.2% |

Strategic Partner Selection for PTFE Expansion Joints

Evaluate PTFE bellows manufacturers against:

- 15:1 safety factor on burst pressure ratings

- Third-party material verification reports

- On-site welding and installation support

(ptfe bellows)

FAQS on ptfe bellows

Q: What are PTFE bellows used for in industrial applications?

A: PTFE bellows are flexible, corrosion-resistant components used to absorb thermal expansion, vibration, and movement in piping systems. They excel in harsh chemical environments and high-temperature settings, commonly applied in chemical processing, pharmaceuticals, and semiconductor industries.

Q: How do I choose a reliable PTFE bellows manufacturer?

A: Look for manufacturers with proven expertise in fluoropolymer fabrication, ISO certifications, and custom design capabilities. Prioritize suppliers offering pressure testing, material traceability, and compliance with industry standards like ASME or DIN.

Q: Can PTFE bellows withstand extreme temperatures?

A: Yes, PTFE bellows typically operate between -100°C (-148°F) and +260°C (+500°F). Their thermal stability makes them ideal for cryogenic applications and high-heat processes, though performance may vary based on reinforcement materials like stainless steel.

Q: What advantages do PTFE bellows expansion joints offer over metal ones?

A: PTFE expansion joints provide superior chemical resistance, reduced friction, and electrical insulation. Unlike metal joints, they resist pitting and stress corrosion while maintaining flexibility in aggressive media like acids, solvents, and ultrapure water systems.

Q: How are PTFE bellows tested for quality assurance?

A: Reputable manufacturers conduct hydrostatic/pneumatic pressure tests, cycle fatigue analysis, and dimensional inspections. Advanced facilities use scanning electron microscopy (SEM) for material analysis and robotic testing rigs to simulate long-term performance.

Related Products

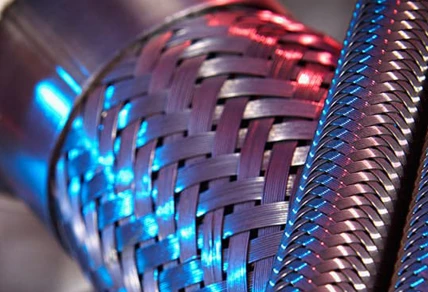

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.