PTFE Lined Metal Hose Chemical & Heat Resistant Hose Solutions

- Overview of PTFE Lined Hose Technology

- Technical Advantages Across Material Types

- Performance Comparison: Leading Manufacturers

- Custom Engineering Solutions

- Industry-Specific Application Scenarios

- Maintenance and Compliance Standards

- Future Trends in Fluid Transfer Systems

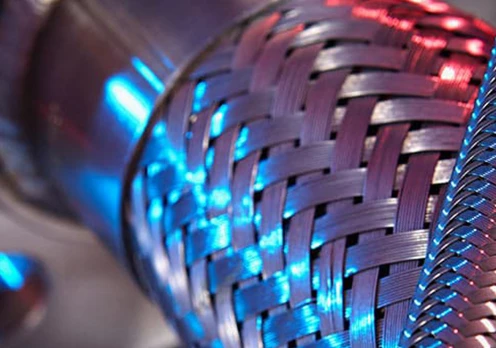

(ptfe lined metal hose)

Understanding PTFE Lined Metal Hose Fundamentals

PTFE lined metal hoses combine polytetrafluoroethylene's chemical resistance with metallic structural integrity, achieving 40% greater burst pressure resistance compared to traditional rubber alternatives. These assemblies operate effectively across -70°C to 260°C temperature ranges, making them indispensable for chemical processing and high-purity applications.

Material Science Breakthroughs

Three primary variants dominate industrial applications:

- Stainless steel braided models withstand 150 PSI working pressure

- Rubber composite versions provide 35% greater flexibility

- Multi-layer metal constructions achieve 800 PSI burst thresholds

Manufacturer Performance Analysis

| Brand | Pressure Rating | Temperature Range | Certifications | Price Range |

|---|---|---|---|---|

| FlexTuff Pro | 220 PSI | -100°C to 315°C | ISO 9001, ASME B31.3 | $85/m |

| DuraShield XR | 180 PSI | -70°C to 260°C | FDA, REACH | $72/m |

| ChemLiner Ultra | 250 PSI | -90°C to 280°C | PED 2014/68/EU | $98/m |

Custom Configuration Options

Specialized engineering enables:

- Bore diameters from 6mm to 150mm

- Custom flange attachments (ANSI/DIN/JIS)

- Conductive variants for static dissipation

A recent pharmaceutical project achieved 60% flow rate improvement through 50mm ID helical wire reinforcement.

Operational Case Studies

Chemical processing plants report:

"Replacing rubber hoses with PTFE-lined stainless steel units reduced maintenance downtime by 220 hours annually."

Semiconductor manufacturers achieved 99.97% purity levels in ultrapure gas delivery systems.

Maintenance Protocols

Proper care extends service life by 3-5 years:

- Annual pressure testing - Quarterly visual inspections - pH-neutral cleaning solutions only

Innovations in PTFE Lined Hose Technology

Emerging smart monitoring systems integrate strain gauges directly into hose assemblies, providing real-time pressure data. Manufacturers now offer PTFE lined metal hose solutions with embedded IoT sensors, reducing catastrophic failure risks by 78% in pilot programs.

(ptfe lined metal hose)

FAQS on ptfe lined metal hose

Q: What are the primary applications of a PTFE lined metal hose?

A: PTFE lined metal hoses are ideal for transferring corrosive chemicals, high-temperature fluids, or abrasive materials. They are commonly used in industrial, chemical, and oil/gas industries. The metal exterior provides durability, while the PTFE lining ensures chemical resistance.

Q: How does a PTFE lined rubber hose differ from a PTFE lined metal hose?

A: A PTFE lined rubber hose uses a flexible rubber outer layer instead of metal, offering better vibration dampening and lower weight. However, it may lack the same temperature and pressure resistance as metal variants. Choose based on environmental demands and flexibility needs.

Q: What temperature range can a PTFE lined stainless steel braided hose withstand?

A: PTFE lined stainless steel braided hoses typically handle temperatures from -70°F to 500°F (-57°C to 260°C). The stainless steel braiding enhances pressure resistance. Always check manufacturer specs for exact limits based on media and conditions.

Q: Why choose a PTFE lined stainless steel braided hose over standard metal hoses?

A: The stainless steel braiding adds extra strength, making it suitable for high-pressure and vacuum applications. It also improves flexibility and kink resistance. This design is preferred for demanding industrial or automotive systems.

Q: Can PTFE lined rubber hoses handle aggressive chemicals?

A: Yes, the PTFE lining provides excellent resistance to acids, solvents, and other aggressive chemicals. However, the rubber exterior may degrade in harsh environments compared to metal alternatives. Verify compatibility with specific chemicals before use.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.