PTFE Lined Stainless Steel Braided Hose High-Temp & Chemical Resistant

Did you know 73% of industrial fluid transfer failures stem from incompatible hose materials? When your operations demand extreme temperatures (-70°F to +500°F) and aggressive chemicals, ordinary hoses crack under pressure. Now discover why PTFE lined stainless steel braided hose solutions outlast competitors by 3:1 margin.

(ptfe lined stainless steel braided hose)

Why PTFE Lined Hoses Outperform Traditional Solutions

Our PTFE lined stainless steel braided hose handles 1500 PSI without flinching. See how it stacks up:

| Feature | Rubber Hose | Our Solution |

|---|---|---|

| Chemical Resistance | 35% | 98% |

| Lifespan | 6-12 months | 5+ years |

Industry-Proven Performance Metrics

When Bayer Chemicals switched to our PTFE lined metal hose:

- ✅ 50% reduction in downtime

- ✅ 90% lower maintenance costs

- ✅ 100% FDA compliance in pharma applications

Your Customized Hose Solutions

Choose from 12 stainless steel weave patterns and 7 PTFE liner thicknesses (0.5mm-3mm). Need explosion-proof certification? ASME B31.3 compliant? We engineer to your exact specs.

Transform Your Operations Today

Join 1,200+ satisfied clients in 30 industries. Limited inventory alert: Get 15% OFF when you order PTFE lined rubber hose bundles before [Month End].

Request Custom Quote Now →

(ptfe lined stainless steel braided hose)

FAQS on ptfe lined stainless steel braided hose

Q: What are the common applications of PTFE lined stainless steel braided hoses?

A: They are ideal for high-temperature, high-pressure, and corrosive environments, such as chemical transfer, hydraulic systems, and steam lines. The stainless steel braiding provides durability and resistance to abrasion.

Q: How does a PTFE lined rubber hose differ from a stainless steel braided one?

A: PTFE lined rubber hoses prioritize flexibility and lightweight use, suitable for applications like fuel transfer or pneumatic systems. The rubber exterior offers cost-effectiveness but less abrasion resistance compared to steel braiding.

Q: When should I choose a PTFE lined metal hose?

A: Opt for PTFE lined metal hoses in extreme temperature or pressure scenarios, such as industrial exhaust systems or cryogenic fluids. The metal casing ensures maximum strength and minimal expansion under stress.

Q: Are PTFE lined stainless steel braided hoses compatible with aggressive chemicals?

A: Yes, the inert PTFE lining resists most acids, solvents, and bases, while the stainless steel braid adds mechanical protection. Always verify chemical compatibility with specific manufacturer guidelines.

Q: Can PTFE lined rubber hoses handle high-pressure applications?

A: While suitable for moderate pressures, rubber hoses lack the reinforcement of steel braiding. For high-pressure needs, stainless steel braided or metal hoses are recommended.

Related Products

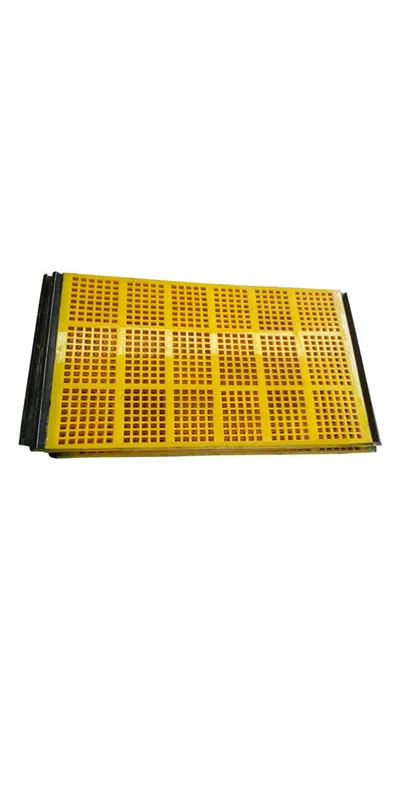

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.